For farm women, especially, the times have brought about significant changes in lifestyles and the nature of responsibilities many have assumed in the operation of the farm business. In a growing number of instances grandmothers, wives, mothers and daughters are being called upon to assist in areas of the farm operation that were traditionally viewed as "man's work." In addition to their already taxing and challenging responsibilities in the home, more faun women appear to be taking on the roles of part-time truck drivers, grain haulers, tractor drivers, and machinery operators.

These new roles, many of which are extremely hazardous, are often assumed by farm women with little or no previous experience or training which greatly increases the risks and likelihood of personal injury. Farming is already one of Indiana's most dangerous occupations and for the inexperienced or untrained part-time worker, man or woman, carrying out hazardous farm operations, regardless of how good the intentions are, can result in tragedy. Therefore, it is the purpose of the Farm Women's Safety Workshop to better equip farm women to safely and efficiently deal with areas of the farm operation that they might be unfamiliar with and that can present special hazards to them. It is also hoped that farm women who participate in the workshop will become more effective at influencing the men in their lives, (husbands, sons, fathers, etc.), who operate farm machinery and perform other hazardous farm tasks to become more safety conscious.

Topics to be covered in the workshop through the use of presentations, demonstrations, publications and audio-visual materials will include:

I. REVIEW OF THE FARM ACCIDENT PROBLEM IN INDIANA

In 1976 Purdue University carried out a survey1 of counties to learn more about the circumstances surrounding non-fatal, farm--related accidents. According to the survey findings:

Besides slips and falls the study also found that the leading accident-causing items around the farm ware:

If the information gathered from the 10 counties were projected over the state's approximately 95,000 farms, the survey suggests that more than 10,500 non-fatal, farm-related accidents occurred during 1976. Of this number it is further estimated that more than 6,000 of the accident victims required emergency medical treatment because of broken bones, internal injuries, burns and lacerations.

Even though the majority of the accidents investigated in the study were work related, a farm family's participation in recreational activities, on and off the farm, contributed to a significant number of serious accidents. As leisure time is used in more sophisticated ways with snowmobiles, motor boats and motorcycles, the possibility of an accident increase. Also, the figures suggest that once a farm family is away from the hazards found on the farm, they may relax and neglect the hazards associated with play.

One encouraging finding of the 1976 farm accident study was the reduction in the accident rate or number of farm accidents per million hours worked between 1970 and 1976. A continued decline in farm population, modern, safer farm equipment, and effective safety education programs, all contributed to the lower accident rate.

II. THE COST OF NON-FATAL FARM ACCIDENTS

Again using the 1976 farm accident study, an estimate of costs of non-fatal farm accidents was computed. Using the average of the approximate costs reported in the survey, it was estimated that a farm accident cost the farm family $373.00 in 1976. Taking into consideration a modest inflation rate of 10 percent per year this figure approaches $550.00 today. This cost includes only direct expenses for medical care, repair or replacement of property and replacement labor. Indirect costs for such items as travel to obtain medical treatment, increased insurance rates, and lost productivity can significantly increase the cost of a farm accident.

Projecting the accident cost figures over the entire state the findings suggest that non-fatal farm accidents cost Indiana farmers nearly $4,000,000 in direct costs during 1976, which potentially might be as high as $6,000,000 today.

III. FUNDAMENTAL CAUSES OF FATAL FARM ACCIDENTS

For more than 15 years an arrangement has been maintained with the Indiana State Board of Health whereby copies of death certificates reporting farm-related fatalities have been provided to the Extension safety specialist at Purdue for analysis. Between 1973 and 1976, 199 death certificates were received and cataloged.

This four-year summary of fatalities does not include those deaths caused by automobile, truck or other highway vehicle accidents, accidents away from the farm resulting from leisure activities and deaths resulting from mishaps in the home. Furthermore, because of present reporting techniques, deaths that could have been attributed to un-diagnosed pesticide poisoning, exposure to silo gas, heart attacks and strokes caused by over exertion and heat, and sicknesses caused by exposure to livestock are not reported in the manner they possibly should be.

Indiana Farm-Related Fatalities, 1973-1976.

Number Percent

Cause reported of total

------------------------------------------

Tractors 97 48.8

Farm machinery 40 20.1

Falls 15 7.6

Smothering or

asphyxiation 13 6.5

Cutting or

trimming trees 11 5.5

Electrocution 4 2.0

Fires and burns 4 2.0

Drowning 3 1.5

Train crossing 1 0.5

Livestock 1 0.5

Other 10 5.0

----------------------------------------

TOTAL 199 100%

---------------------------------------

Of real concern should be the finding that of the 154 tractor and machinery-related deaths which happened between 1973 and 1976, 25 were children under the age of 14 including 9 under 4 years. As long as the practice of carrying an "extra rider" on farm machinery continues to be accepted by many Indiana farm families there undoubtedly will be little reduction in this type of accident. Even tractor cabs, which appear as safe places to babysit small children or to provide an older child with a place to ride along, presents risks which a family should carefully consider before permitting the practice. For there is probably nothing that can destroy or tear apart a farm family quicker or more permanently than the tragic loss of a little one because of a needless farm accident.

IV. SAFE OPERATION OF FARM TRACTORS

A. Audio-Visual presentation on Safe Tractor Operation

As you watch the film, "Agricultural Tractor Safety"2, which is to be presented at this time, see if you can correctly answer the following questions. At the completion of the film showing, the questions will be used as a basis for further discussion. Circle TRUE or FALSE:

1. TRUE or FALSE: Most fatal farm machinery accidents involve tractors.

2. TRUE or FALSE: The majority of farm machinery accidents are

caused by improper machine design.

3. TRUE or FALSE: Accidents cause more deaths to young people

between the ages of 15 and 24 than all other

causes combined.

4. TRUE or FALSE: ROPS on tractors help prevent tractor roll overs.

5. TRUE or FALSE: Loads being towed by a tractor should only be

attached to the drawbar.

6. TRUE or FALSE: All new farm tractors and machinery are designed

so that hearing protection for the operator

is not required.

7. TRUE or FALSE: Tractor engines should never be run in an enclosed

area such as a machinery building with the doors

closed.

8. TRUE or FALSE: Then operating a tractor on the highway both brakes

should be locked together.

9. TRUE or FALSE: The SMV emblem can be used on farm equipment to

replace other warning devices such as reflectors

and tail lamps.

10. TRUE or FALSE: The primary reason for shutting off a tractor

engine while refueling is to conserve fuel.

See last page for answers.

B. Tractor Activity Checklist

Using the assigned tractor work stations, complete the following

activity checklist which is designed to assist you in identifying

potential hazards and to batter understand the safety aspects of each

tractor. If you have any questions ask the resource person located at

each work station.

1. On the tractors at each work station inspect for the following hazards

which have the potential for causing a personal injury.

blkb

Tractor Tractor Tractor

#1 #2 #3

______ _______ _______ 1. Trash or tools on platform

______ _______ _______ 2. Fuel system leaks

______ _______ _______ 3. PTO master shield missing

______ _______ _______ 4. Faulty muffler

______ _______ _______ 5. Unevenly adjusted brakes

______ _______ _______ 6. Dirty or faded SMV emblem

______ _______ _______ 7. Improper tire inflation

______ _______ _______ 8. Broken or non-functioning

headlights, tail lights and

reflectors

______ _______ _______ 9. Missing hazard-alert sym-

bols and safety decals

______ _______ _______ 10. Key left in the ignition

Others (describe): _________________________________________

___________________________________________________________

___________________________________________________________

2. Locate the following safety items on the tractor at each of the work stations. (In the process of completing this activity, compare the number of safety items found on the newest tractor with the number found on the oldest tractor)

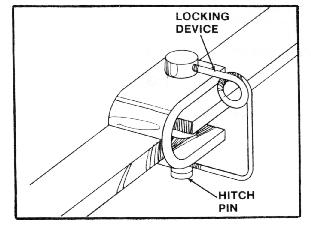

Tractor Tractor Tractor #1 #2 #3 ______ _______ _______ 1. ROPS ______ _______ _______ 2. SMV emblem ______ _______ _______ 3. Hazard-alert symbols and safety decals ______ _______ _______ 4. PTO master shield ______ _______ _______ 5. Protective PTO shaft shield ______ _______ _______ 6. Neutral start switch ______ _______ _______ 7. Tail lights and reflectors ______ _______ _______ 8. Hand holds and steps ______ _______ _______ 9. Fire extinguisher ______ _______ _______ 10. First-aid kit ______ _______ _______ 11. Adjustable seat ______ _______ _______ 12. Safety hitch pin

3. Locate the following gauges and meters on the tractor at each of the assigned work stations.

Tractor Tractor Tractor

#1 #2 #3

_______ _______ ________ 1. Fuel level indicator

_______ _______ ________ 2. Coolant temperature gauge

_______ _______ ________ 3. Engine oil pressure gauge

_______ _______ ________ 4. Electrical ammeter or generator light

_______ _______ ________ 5. Transmission oil temperature

gauge

_______ _______ ________ 6. Air cleaner restriction light

_______ _______ ________ 7. Engine hour meter

_______ _______ ________ 8. Engine RPM indicator

4. On the tractor at each work station locate and operate each of the following controls.

Tractor Tractor Tractor

#1 #2 #3

_______ _______ ________ 1. Start switch

_______ _______ ________ 2. Engine throttle lever

_______ _______ ________ 3. Fuel shut-off control on diesel tractors

_______ _______ ________ 4. Light switches

_______ _______ ________ 5. Seat adjustments

_______ _______ ________ 6. Clutch petal

_______ _______ ________ 7. Brakes and brake locks

_______ _______ ________ 8. PTO activating lever

_______ _______ ________ 9. Three-point lift control

lever

_______ _______ ________ 10. Remote hydraulic ram control

levers

_______ _______ ________ 11. Differential lock mechanism

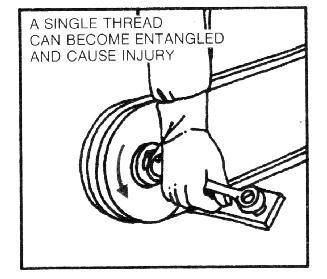

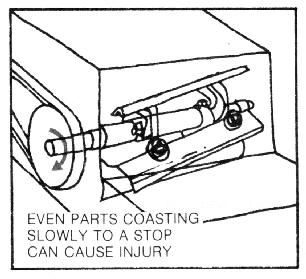

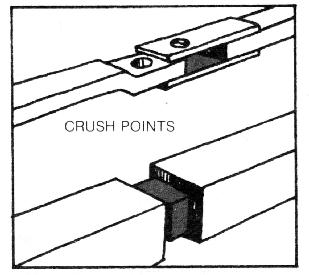

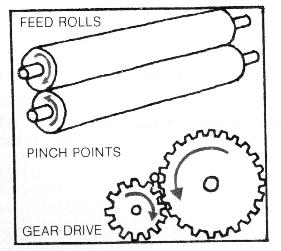

V. IDENTIFYING AND AVOIDING HAZARDS ON SELECTED PIECES OF FARM MACHINERY The moving parts of any machine, whether they are on a baler, combine, manure spreader or even a lawnmower, are faster and more powerful than you are. These crushing, pinching and cutting parts are also no respector of age, sex or income bracket. A high speed blade on a sickle bar can slice off a finger faster than you can think about it. The power shaft on a forage harvester can grab loose clothing and with a force hundreds of times greater than all your physical strength entangle you into a certain death trap.

It is tremendously important that all who work with farm machinery develop and continually maintain a conscious respect for its potential of causing injury. The Scriptural reference to "pride coming before the fall" is truly applicable to those who work with farm machinery. For as soon as the user lets down their guard or becomes over confident, trouble is certain to be on the way.

As you are assisted in identifying potential hazards on the various pieces of farm machinery at each of the work stations, be on the alert for the following items:

1. Safety

Decals

2. Safety

Hitch Pins

3. Moving Parts That Can Entangle

4. Moving Parts That Can Shear

5. Moving Parts That Can Pinch

VI. GRAIN HANDLING SAFETYA considerable number of suffocations end entrapments in flowing grain have taken place during the last few years. A recent Purdue study3 identified 61 separate incidences of flowing grain entrapment or suffocation in which 38 Indiana farmers or members of their families died. Over 40 percent of the suffocations involved young children.

While viewing the slide-tape presentation4 on the hazards of flowing grain make an attempt to answer the following questions. The questions will be used as a basis for discussion following the presentation. Circle TRUE or FALSE:

1. TRUE or FALSE: There is no good excuse for entering a grain

bin with the unloading equipment operating.

2. TRUE or FALSE: Entrapment in flowing grain can occur in as

little as 2 or 3 seconds.

3. TRUE or FALSE: The only hazard caked or spoiled grain presents

is from inhalation of mold and dust.

4. TRUE or FALSE: Illness caused by inhalation of moldy grain dust

is only temporary and should not be considered

serious.

5. TRUE or FALSE: Dust masks that are effective for providing

protection from grain dust are readily

available in most farming communities.

6. TRUE or FALSE: Grain bins should be "off-limits" to children

at all times.

7. TRUE or FALSE: Grain wagons and grain hauling trucks are an

unlikely place for a flowing grain accident

to happen.

8. TRUE or FALSE: The use of ropes and ladders suspended from the

ceilings of grain bins have been proven as

effective safety devices to prevent grain bin

accidents.

9. List four reasons why flowing grain accidents occur on modern Indiana farms.

a.

b.

c.

d.

10. List four possible preventive measures a farm family could take to reduce the possibility of a flowing-grain accident.

a.

b.

c.

d.

See last pages for answers.

VII. HANDLING FARM CHEMICALS SAFELY (optional, depending upon time)

In one respect, farm chemicals are similar to farm women in that it is common to see men who work with both quickly take each for granted. In both cases this situation can lead to a pile of trouble. (Since this workshop is dealing primarily with farm safety and not interpersonal or marital relationships we'll attempt to keep our focus on the safe use of farm chemicals.)

Farmers use thousands of chemicals to control a wide variety of pests that reduce the productivity of agricultural crop land and livestock and to protect farm products once they are produced. The risk to health and life may be substantial if these farm chemicals are handled carelessly.

Even though there have been very few deaths from the use of farm chemicals it is believed that many non-lethal reactions to farm chemicals go unreported or are ignored by farm families. In some cases accidental exposure to certain farm chemicals can result in symptoms that could easily be passed off as a stomach upset or a "bad case of nerves" during a busy planting period. It is most important that members of farm families, especially farm wives, be keenly aware of not only the symptoms of acute exposure to certain toxic chemicals but also the chronic or long term effects that chemicals may have.

One chemical that is widely used in Indiana as a fertilizer is anhydrous ammonia. This chemical can present some real hazards to the uninformed user. Accidents involving anhydrous ammonia can result in serious injury, blindness or even death. Because of the tremendous amount of anhydrous ammonia used in Indiana and it's potential to cause injury, information on its safe handling and use is included in the Farm Women's Safety Workshop.

As you view the next film presentation5 covering anhydrous ammonia safety be alert for tips that you could pass along to those in your family who might be involved with the use of this chemical. Use the following questions as a guide.

1. Why is anhydrous ammonia hazardous to handle?

2. Why is an emergency supply of water so important?

3. What personal protective equipment should be used at all times when handling anhydrous ammonia?

4. What are the proper first-aid procedures for victims injured by anhydrous ammonia?

VIII. CONCLUSION

No one program, regardless of how well it is carried out, will make you safe and proficient at handling all hazardous farm related tasks. Hopefully today's workshop allowed you to develop a few new skills, become aware of hazards that you didn't realize existed before and sharpened your desire to encourage your family to become more safety conscious.

There are a number of safety publications available on a wide variety of topics which you might find useful in assisting your family members to become inure aware of specific farm hazards. Feel free to inquire about them at your county Extension office or contact the Extension Safety Specialist, Department of Agricultural and Biological Engineering, Purdue University, West Lafayette, Indiana, 47907.

Answers

IV.-A. Audio-Visual Presentations on Safe Tractor Operations

1. (TRUE), 2. (FALSE), 3. (TRUE), 4. (FALSE), 5. (TRUE),

6. (FALSE), 7. (TRUE), 8. (TRUE), 9. (FALSE), 10. (FALSE).

VI. Audio-Visual Presentation on Hazards of Flowing Grain

1. (TRUE), 2. (TRUE), 3. (FALSE), 4. (FALSE), 5. (TRUE),

6. (TRUE), 7. (FALSE), 8. (FALSE).

9. (harvesting, handling and storing of shelled corn), (more

on-farm storage) , (larger bins), (greater handling capacity)

and (year-round storage of grain)

10. (warn all family members of the hazards of flowing grain)

(put warning signs on bins and wagons) , (prohibit children

from entering bins and riding in grain wagons), and (have

two people present when grain is being unloaded from bins)

VII. Audio-Visual Presentation on Anhydrous Ammonia

1. (anhydrous ammonia is a strong alkali which is transported,

stored and handled under pressure)

2. (water is the only effective first-aid treatment for

exposure to anhydrous ammonia).

3. (chemical-type goggles) and (rubber gloves).

4. (Flood affect areas with water for 15 minutes), (remove

contact lens if present) , (remove contaminated clothing)

and (seek medical attention)

Footnotes

RR 5/81

Publication #: S-83

Purdue University Cooperative Extension Service

West Lafayette, IN 47907

Bill Field

Extension Safety Specialist, Department of Agricultural Engineering

Cooperative Extension work in Agriculture and Home Economics, state of Indiana, Purdue University, and U.S. Department of Agriculture cooperating; HA. Wadsworth, Director, West Lafayette. IN. Issued in furtherance of the acts of May 8 and June 30, 1914. Purdue University Cooperative Extension Service is an equal opportunity/equal access institution

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More