Farm machinery uses power to do work. This creates a number of possible hazards for both operators and bystanders. Even though manufacturers take many steps to make machinery safe, all hazards cannot be removed.

Most accidents with machinery are the result of human error. The operator either forgot something, took a shortcut or a risk, ignored a warning, wasn't paying close attention or failed to follow safety rules.

In many cases, accidents with farm machinery are very serious, even fatal. It is important to recognize and be alert for machine hazards and to take precautions to avoid injury.

There are many different kinds of farm machinery--mowers, tractors, shredders, harvesters, grinders, blowers, augers, balers, etc.--but they all have similar characteristics and similar hazards. You can be cut, crushed, pulled in or struck by an object thrown by these machines. They have cutting edges, gears, chains, revolving shafts, rotating blades, levers and similar hazards. You can also be injured if you fall while working from or near any of these machines.

Another problem with machinery is that some machine parts cannot be completely shielded and still do their job. For instance, a cutting blade cannot be totally enclosed, or it could not cut. In addition, guards which can be removed for maintenance often don't get replaced.

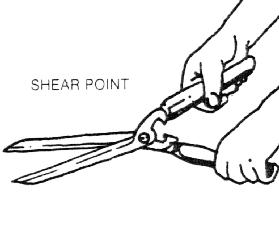

Shear points are created when the edges of two objects are moved closely enough together to cut a soft material, as in the case of a pair of shears or an auger. Cutting points are created when a single object moves forcefully or rapidly enough to cut, as in the case of a sickle blade.

Both shear and cutting points are created on machinery designed to cut, as in harvesters, and on those that are not designed to cut, as in an auger. They are hazards because of their cutting force, and because they often move so rapidly that they may not be visible, so it is easy to forget that it is operating.

Because some cutting and shearing points cannot be guarded, it is important to be aware of their hazard and to be especially alert when they are operating. It is also important to warn others and to look out for their safety, because of the danger of thrown objects while using cutting-type equipment.

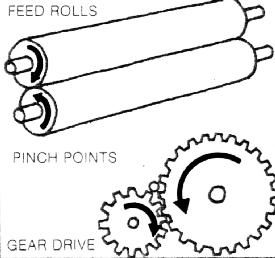

Pinch Points

Another hazard of farm machinery is the pinch point. Pinch points are formed when two rotating objects move together and at least one of them moves in a circle. For example, the point at which a belt runs onto a pulley is a pinch point. Belt drives, chain drives and gear drives are other sources of pinch points in power transmission devices. Feed rolls, gathering chains and similar equipment to draw crops into the machine also create pinch points.

Fingers, hands and feet can be caught directly in pinch points,

or they may be drawn into the pinch points by loose clothing

that becomes entangled. Contact may be made by just brushing

against unshielded parts or by falling against them. You can

become entangled in pinch points if you take chances and reach

or work near rotating parts. Machines move too fast to get

out of a pinch point once you become caught in it.

Fingers, hands and feet can be caught directly in pinch points,

or they may be drawn into the pinch points by loose clothing

that becomes entangled. Contact may be made by just brushing

against unshielded parts or by falling against them. You can

become entangled in pinch points if you take chances and reach

or work near rotating parts. Machines move too fast to get

out of a pinch point once you become caught in it.

To avoid injury from pinch points, be aware of the areas where pinch points occur and avoid them. Wear clothing that fits well and is not loose or floppy. Never reach over or work near rotating parts. Turn off machinery to work on it. Always replace shields if you must remove them for maintenance.

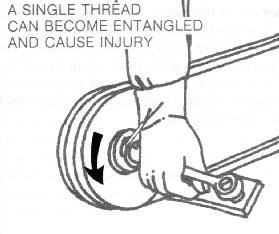

Wrap Points

Rotating shafts are the most common source of wrap point accidents, although any exposed machine part that rotates can be a wrap point. A cuff, sleeve, pant leg or just a thread can catch on a rotating part and result in serious injury. Entanglement with a wrap point can pull you into the machine, or clothing may become so tightly wrapped that you are crushed or suffocated. In other cases, you could be thrown off balance and fall into other machine parts.

Even a perfectly round shaft can be a hazard if there is enough pressure to hold clothing against the shaft. Shafts that are not round increase the hazard significantly. Clothing is more likely to catch if there is a little mud or dried manure, or a nick on the shaft. Ends of shafts which protrude beyond bearings are also dangerous. Universal joints, keys and fastening devices can also snag clothing.

Check all equipment for potential wrap points, and shield those that can be shielded. Place warnings on those that cannot be covered, or paint them a bright color, perhaps with wide stripes. Be aware of wrap points and be alert to their danger.

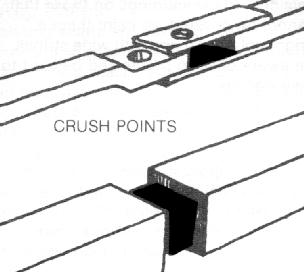

Crush points are created when two objects move toward each other or one object moves toward a stationary one. For example, hitching tractors to implements may create a potential crush point.

Failure to block up equipment safely can result in a fatal crushing injury. A jack may slip, a hose or overhead support may break, or the equipment may roll. Be sure to take extra precautions when working with machinery that is raised for any reason.

Crushing injuries most commonly occur to fingers that are

crushed at the hitching point. Wait until the tractor has

stopped before stepping into the hitching position. If possible

arrange the hitch point so that the tractor can be backed

into position without anyone between. Always know what the

other person is doing.

Crushing injuries most commonly occur to fingers that are

crushed at the hitching point. Wait until the tractor has

stopped before stepping into the hitching position. If possible

arrange the hitch point so that the tractor can be backed

into position without anyone between. Always know what the

other person is doing.

The head or chest of an operator may be crushed between the equipment and a low beam or other part of a farm building. Usually, these accidents occur when operating the machine in reverse Tree limbs are also potential hazards when working with tractors and other machinery.

To prevent being crushed or pinned, first, recognize the potentially dangerous situations. Then, avoid them whenever possible. Block all machinery securely if you must work under it. If an implement can roll freely, block its wheels so it cannot roll.

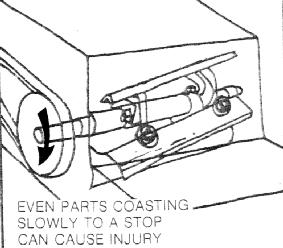

Free-Wheeling Parts

Many machine parts continue to spin after the power is shut off; for instance, cutter heads of forage harvesters, hammer mills of feed grinders, rotary mower blades, fans, flywheels, etc. Never touch these parts until they have stopped moving completely. This may take as long as 2 - 2 1/2 minutes.

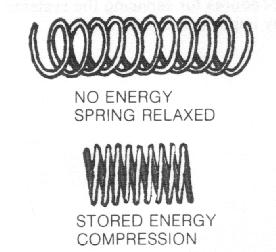

Springs

Springs under compression will expand with great force when released, and springs that are stretched will contract rapidly when released. Know what direction a spring will move and how it might affect another machine part when released, and stay out of its path.

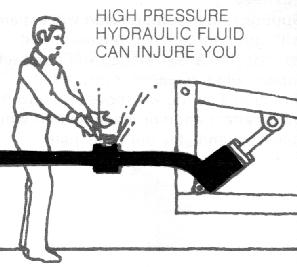

Hydraulic Systems

Hydraulic systems contain fluid under very high pressure. Before loosening, tightening, removing or otherwise working with any fittings or parts, relieve this pressure. Jet streams from even pin-hole leaks can penetrate flesh. In addition, the liquid is often hot. Before attempting any service on hydraulic systems, shut off the engine which powers the hydraulic pump. Lower the implement to the ground and relieve the pressure. Follow the instructions in your operator's manual, because the specific procedures for servicing the systems are very important to your safety.

If You Are Under 16 ....

A federal child labor law affects you. Unless you are working for your parent or guardian on a farm owned or operated by that person, you are not permitted to operate a tractor over 20 pto hp and certain other farm machines, although some of these jobs can be started at age 14 if you have special training. Check with your county Extension office for further details.

Young people under 14 may be employed to do any job that is not classified as particularly hazardous if they have the written consent of their parent or guardian. There is one exception: children under 12 are not permitted to work on farms that used 500 or more man-days of labor during any quarter of the preceding calendar year.

New 1/77

Publication #: S-73

Purdue University Cooperative Extension Service

West Lafayette, IN 47907

Prepared by F. R. Willsey, former Purdue staff member in Agricultural Engineering

Approved for reprinting by Bill Field, Extension Safety Specialist

For more information, contact Bill Field, Agricultural and Biological Engineering, phone: 317-494-1191 or e-mail: field@ecn.purdue.edu

Cooperative Extension work in Agriculture and Home Economics, state of Indiana, Purdue University, and U.S. Department of Agriculture cooperating; HA. Wadsworth, Director, West Lafayette. IN. Issued in furtherance of the acts of May 8 and June 30, 1914. Purdue University Cooperative Extension Service is an equal opportunity/equal access institution

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More