Good safety practices and good management go hand in hand.

We, as tobacco producers, realize that at busy times of the

year every minute counts. We do not need to be losing time

because an accident has occurred and we need to find a replacement

worker.

We need to remember that ACCIDENTS HURT, ACCIDENTS COST,

AND ACCIDENTS CAN BE AVOIDED. In 1995, there were 166

lost time injuries reported to the Workers' Compensation Board

in Ontario from tobacco farms. Many of these injuries could

have been avoided by taking the time to ensure that equipment

and facilities were safe and that proper instruction was given

to employees. "Lack of time" is no excuse to be lax with safety.

When we are stressed and preoccupied with the work at hand,

safety practices often suffer both on the farm and on the

roadways.

When we all work together, accidents and costs can be reduced

along with your stress levels.

The purpose of these guidelines is to remind producers of their

responsibility as it applies to the health and safety on the

farm. These guidelines will offer reminders of items to consider

prior to each operation so that safety becomes a priority. These

guidelines will also provide you with references and other sources

of information which you may use to comply with accepted safety

standards.

Examples used in these guidelines are actual accidents, some

of which have occurred on tobacco farms.

FARM

TRACTORS

The farm tractor is one of the most used pieces of equipment

on today's tobacco farm. Most farms will have more than one

tractor, often of different sizes and used for different tasks.

It is also the

most dangerous piece of machinery you

will encounter. Farm tractors have killed 250 people on Ontario

farms in a recent fifteen year period. Many of the deaths have

involved rollovers to the side or rear, extra passengers falling

from the tractor and bystanders being run over. There are a

number of basics that you must know about if you are to keep

yourself, your family and your employees safe.

Tractor

Rollovers

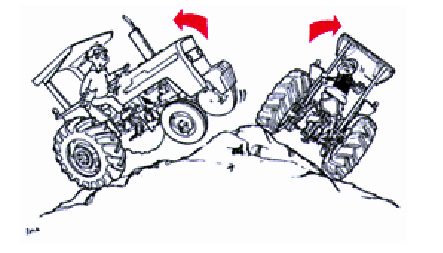

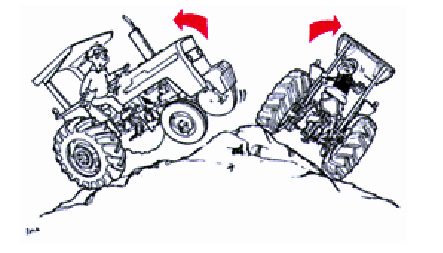

Rollovers account for about one-half of all tractor fatalities

on our farms. The chief causes of these rollovers include:

- Driving

too fast for conditions

- Striking

surface irregularities such as rocks, stumps and holes

- Short

turns at high speeds

- Running

into ditches

- Hitching

high for extra traction

- Driving

on steep slopes

- Improper

operation of front-end loaders

You can

avoid tractor rollovers to the side by:

- Setting

your wheels at the widest spacing possible for the job at

hand.

- Don't

attempt to cross excessively steep slopes.

- Watch

constantly for depressions and obstacles. If stability becomes

uncertain on sloping land, turn downhill!

- Match

your speed to conditions and loads. Don't let your tractor

bounce.

- Lock

brake pedals together before high speed travel, and slow

down before turning.

- Use

engine braking when going downhill.

- Stay

at least as far away from ditches and streams as they are

deep.

- Keep

a front-end loader bucket as low as possible.

You can

avoid tractor rollovers to the rear by:

- Never

hitching a load higher than the drawbar.

- Use

proper weights to increase tractor stability.

- Start

forward motions slowly and increase speed gradually.

- If

possible, avoid backing downhill.

- Drive

around ditches not across them.

- Back

your tractor out when mired in mud. If this won't work,

the only safe way is to tow the stuck machine out with another

tractor that has rollover protection.

If

your tractor has a loader attached

to it, lower the loader to the ground when not in use. Workers

can walk into a raised loader while carrying items or while

having vision obstructed.

Training new operators thoroughly in tractor operation

is a must! Even if your tractor operator has used tractors

before, they may have been different makes or models with

controls in different locations. Take the time to review the

safety rules and hazards associated with tractor operation.

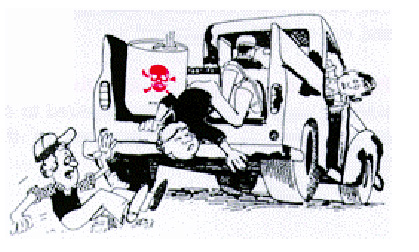

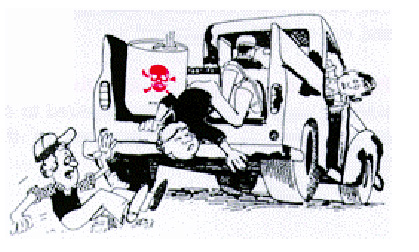

Pesticides are not only toxic to humans, they can be even more

toxic to fish, birds and other wildlife. Follow instructions

to protect yourself and the environment.

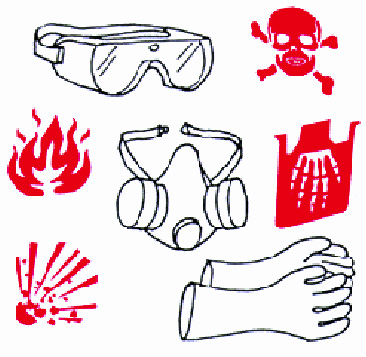

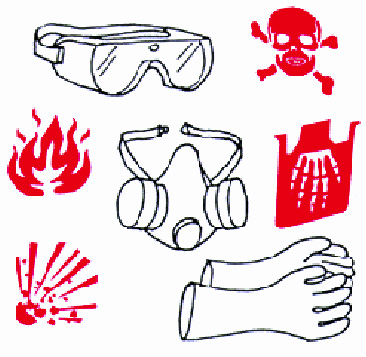

When using

any farm chemicals you must read the label

thoroughly to determine what safety equipment you need for handling,

mixing, and applying the chemical. Always follow safety precautions

in accordance with the label.

When applying

chemicals, wear a respirator if required as well as other prescribed

equipment. Pay attention to spray drift and take necessary precautions.

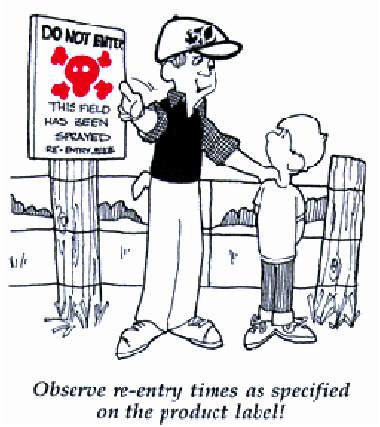

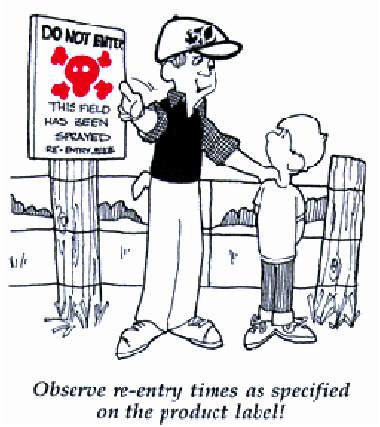

Do not apply chemicals when workers are in the fields or

greenhouses and observe re-entry times according to label

instructions. Greenhouses are confined spaces and chemical concentrations

can be higher than in open fields.

Chemical containers should be triple rinsed with water added

to the spray tank. This is because as much as 3% of the original

formulation can be left in a container. It could be dangerous

to other people if left without rinsing. The rinsed containers

should be recycled where possible. Check with your chemical

supplier or Ministry of the Environment to determine the nearest

drop off site near you. Where allowable, paper or cardboard

containers may be burned, ensuring that people and animals are

kept away from the smoke and that the smoke is not directed

towards buildings, highways, roads or public outdoor areas.

Chemical

storage locations must be posted with a warning sign!

Chemicals

must be stored in accordance with the regulations set out in

the Pesticides Act. Chemicals should be locked in a secure storage

area vented to the outside atmosphere. A placard bearing the

words "CHEMICAL STORAGE WARNING - AUTHORIZED PERSONS ONLY" must

be affixed to the entrance. There should be no floor drain that

goes into any sewer or water course. Pesticides must be stored

in their original containers and off the ground if the possibility

of flooding exists.

Safety information on farm chemicals is contained in the

Tobacco

Production Recommendations published by OMAFRA.

Other safety information is available from your pesticide certification

program or the Farm Safety Association.

You can obtain

Material Safety Data Sheets from your supplier

for each chemical when you purchase it.

Be extremely careful when working with fumigants.

Fumigant

gases are highly toxic.

When using

fumigants wear the appropriate protective

equipment to prevent skin and inhalation exposure.

When using formaldehyde follow the recommended procedures

on the label including the use of proper protective equipment.

Formaldehyde is used to control moss and pole rot. Remember

that a closed kiln or greenhouse is a

confined space!

When using formaldehyde to dip sticks make sure that people

carrying out this operation wear sufficient protection against

splash or vapors.

Sprayer

equipment should be in top shape. Use caution with high clearance

sprayers as their stability can change with terrain, speed and

quick turns. These have been known to flip over.

For Chemical

Safety Precautions in the Greenhouse, please refer to the chemical

safety section in this booklet.

Before seeding the greenhouse, you should perform a detailed

inspection taking notes on items which need immediate attention.

Some of these will include:

Replacing greenhouse glass:

Gloves and eye protection are a must for this operation. Any

ladders that you use should be inspected and in good condition.

Housekeeping and cleanup: Make sure that areas in and

around the greenhouse are free of debris and other items which

can cause hazards.

Water lines and pipes: Inspect your water supply lines for

wear and tear and replace worn out hoses and taps if necessary.

If overhead pipes have created a hazard where employees have

walked into them or bumped their heads often, consider moving

them higher or elsewhere, if possible.

Electrical cords and outlets: Have your wiring checked

before starting up. Any extension cords that you use should

be inspected and repaired if necessary. Check for cracks in

insulation and wear at the connecting ends.

Consider the wet environment they will be in.

Electricity

and water are a deadly mixture. Installing ground fault

circuit interrupters in your system is a good safety measure.

They could save a life if equipment shorts out. Check the electrical

system

before start-up.

The victim was doing general maintenance when the aluminum ladder

the victim was using came into contact with hydro wires. Cause

of death was electrocution.

Fans should be guarded: Employees or children should

be protected from coming into contact with fan blades. Make

sure that some form of shield or guard is in place on

both

sides of the fan. The mesh on any screen guard should be

small enough to prevent fingers from going through and contacting

fan blades. Regular maintenance will reduce wear and the noise

produced while operating.

Use care when steaming with plastic! As you lift the

plastic, steam can escape and hit you causing severe burns.

Anticipate this, and don't rush!

Steamers should be thoroughly inspected: Use caution

around steamers at all times. Burns can be common, so use gloves.

Cold weather can lead to icy conditions around the steamer.

Correct these conditions or slips and falls could result. Check

all electrical connections, quick couplers, condition of hoses

and pans, gauges and valves. Steam pans and lifters may need

maintenance and alignment. Plan your steaming. Ask yourself,

what didn't go right last year?

Check power floats: Check the electrical system on the

power float before work starts. Make employees aware of potential

pinch points and place warning decals on areas which cannot

be guarded and which present a hazard to workers. All workers

should be taught how to reverse or shut off power floats.

Make

sure that you stop the float before getting on or off.

Manually operated floats: Check the condition of the boards,

centering, alignment for floats, surfaces traveled on for smoothness,

condition of wheels and guide wheels as well as lubrication

for easy, quiet use.

When spreading vermiculite: Make sure that workers are protected

with dust masks and eye or face protection.

Post warning signs or re-entry times: Post warning signs

where you are required to do so according to label instructions

of the chemicals used.

Store and transport planting chemicals safely!

Perform pre-planting maintenance: Carry out an inspection

of all equipment and machinery you will be using during planting

including planters, wagons, water tanks, tractors, etc. Pay

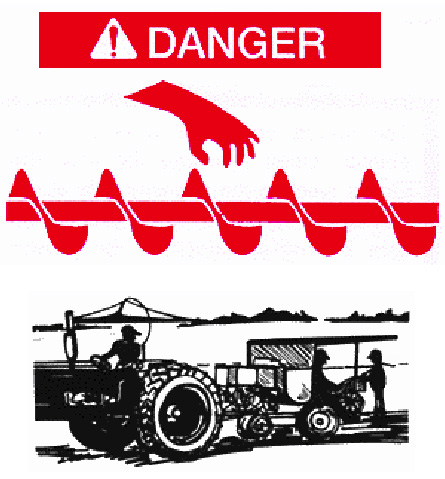

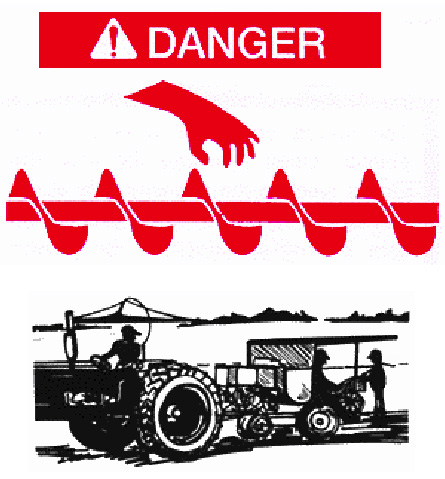

attention to any sharp edges, corners or projections which can

cause injury and correct them. Place warning decals on machinery

where hands can become caught in augers, chain drives, belts

and pulleys.

Proper clothing is a must! This applies to both you and

your employees. Dangling scarves, loose long hair, shoe laces,

frayed clothing and tie cords can become caught in moving parts

of machinery such as planters, and fertilizer augers.

Get your signals straight. Communication is very important

to safety, especially around noisy equipment.

Make sure that

everyone knows what signals mean for stopping, starting, etc.

Make sure that everyone knows the rules: no one gets on or off

of a piece of equipment while it is moving!

Watch for bystanders: Before starting to move any piece

of equipment, make sure there is no one near it, especially

small children who can be run over. Do a quick walk around if

necessary. It only takes a few seconds.

Ensure that water tanks are secure: This applies to tanks

on both trucks and wagons. Check tires for wear and their ability

to hold a heavy load

before filling the tank. If wagons

will be traveling on public roadways make sure they have adequate

safety chains and a slow moving vehicle sign on the rear. When

wagons are parked, block the wheels to keep them from rolling.

Make sure you use safe lifting techniques: Employees

should be instructed in safe lifting techniques to prevent possible

back injury. When lifting plant boxes or fertilizer bags,

bend

at the knees and use your legs for lifting...don't stoop!

Turn your feet before walking, don't twist with your lifted

load.

Use team work: assign specific tasks to each worker for

re-filling planter with plants, fertilizer, water, etc. An organized

team operates more efficiently and safely!

When handling fertilizers consider wind conditions before

filling the planter. A dust mask and eye protection may be appropriate.

A supply of fresh water should be available for washing or to

use as an eyewash if needed.

Use caution when operating fertilizer

augers.

The victim had been working on a planter. Upon finishing the

row, the victim went to the opposite side at the rear of the

machine, and could not be seen by the operator. As the planter

was backed up, it knocked the victim down and its wheel passed

over the victim's entire right side.

Tag your equipment if parts are worn or need to be replaced

before next season. These tags act as reminders to fix it before

using it. Remember, breakdowns cost time and money!

Is your pond fenced?: If your farm pond is easily accessed

by the public or if small children can wander near it, you should

consider some form of fencing which will prevent a tragedy from

occurring on your farm.

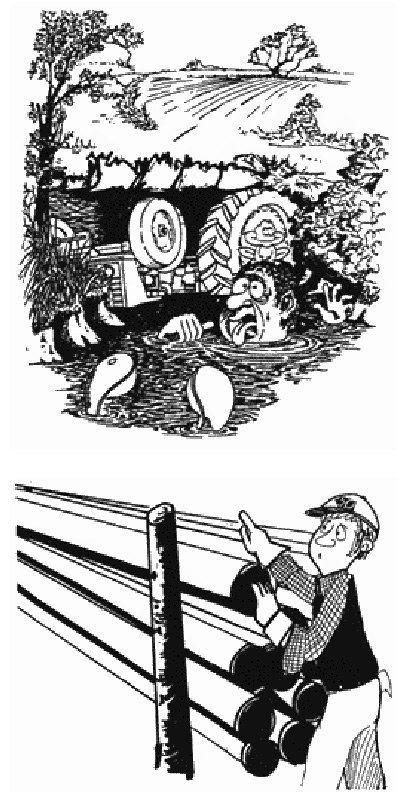

Machinery access to ponds, or creeks: Some ponds or creeks

are located in areas where it is difficult to get machinery

in and out. If possible, try to design a safe access point,

particularly if employees or contractors will be operating the

equipment.

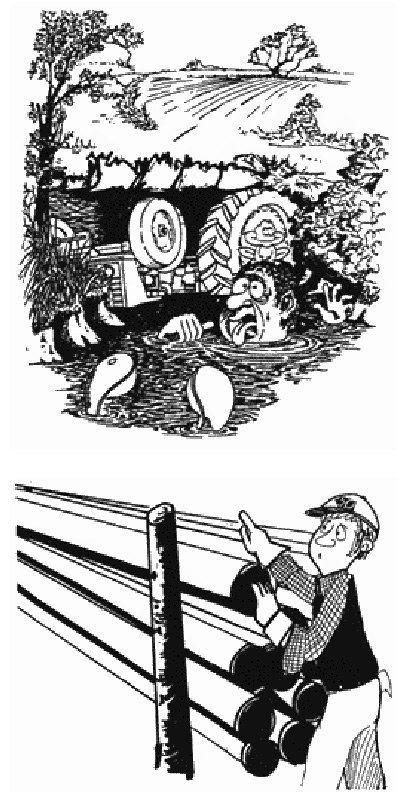

The victim was operating a farm tractor and while reversing,

drove over the edge of the bank and into a pond. The victim

was pinned underneath the tractor in the pond.

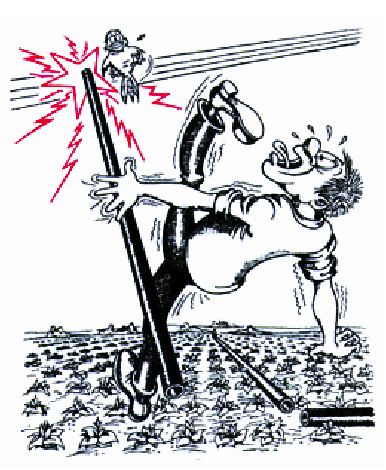

Inspect all pipes and irrigation equipment: This should

be done prior to using it.

Gloves and work boots are a must

for handling pipes. Use caution when moving or raising pipes

-- always look for overhead powerlines to prevent electrocution.

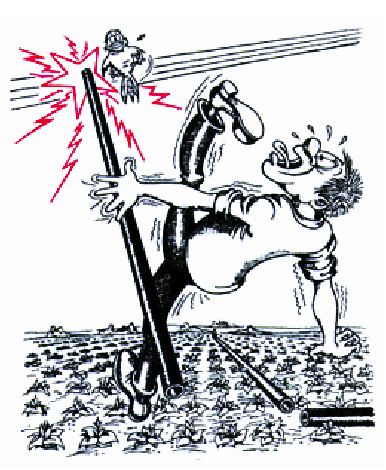

The victim and another person were laying irrigation pipes from

one farm to another. They were attempting to put a 30 foot pipe

into a culvert under the road. Since the culvert had filled

with sand they kept pulling the pipe out to clear the sand.

While doing this, the pipe came into contact with a 4800 volt

hydro line and electrocution resulted.

High voltage power lines: Consider the location of these

lines when setting up your irrigation system and determining

where water is to be sprayed. Contact can sometimes lead to

electrocution.

Pipes loaded for transport should be secured before moving

onto the highway.

It's the law!

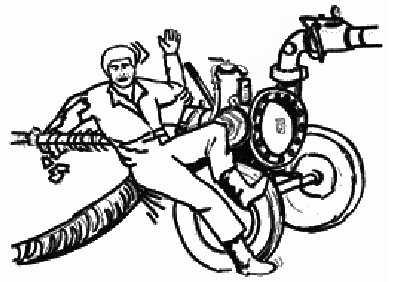

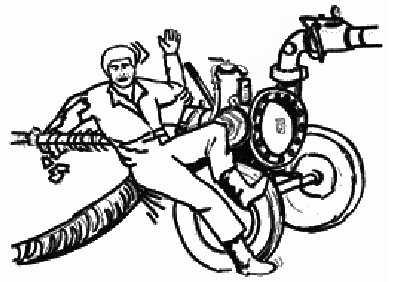

For pumps operated by a power takeoff: Make sure that

there is a PTO safety shield in place and this includes the

master shield on the tractor.

Never, never step over the

PTO shaft!

Use caution around 'travelers' or self-moving irrigation

systems: Mechanical hazards such as chain drives, revolving

shafts, etc., can pose hazards too. Cables on equipment should

be checked for wear and replaced if needed. Plan your adjustments

and repairs to account for the movement and pressure.

When

the irrigation head reverses, the force of its momentum can

cause injuries. Again, watch for powerlines and use caution

around them.

The individual was repairing a traveler while it was running

and got caught in the system and was killed.

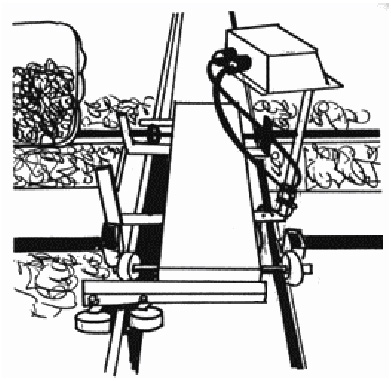

Before harvest, perform detailed inspections on all harvest

equipment and buildings and make repairs where necessary.

Inspect all baskets: Examine both baggy and traditional

baskets for broken steel, cracks, and other hazards which can

cause cuts or other injury.

Shields and guards must be over chain drives, belts and pulleys,

etc. Affix warning decals in these areas as reminders to

employees.

Tobacco rash can be a problem for some workers depending

upon their sensitivity. This reaction to contact with tobacco

should be treated early. Stress the importance of keeping clothing

clean and skin protected to employees. Some have been known

to use the same clothing day after day while harvesting the

crop.

Proper clothing is a must on the priming machine. Loose

clothing, laces and suspenders can all become caught in moving

parts of the machine. Bump caps and proper footwear must be

worn.

No bare feet! Employees should come prepared with

rain suits.

Lightning can be deadly. If a sudden severe storm comes

up, get away from open areas; go into a building or car. Keep

away from water or anything such as metal fences, irrigation

systems, etc. If you sense your hair or skin beginning to tingle,

you may be about to be struck. Crouch low to the ground with

feet together, making you a small target.

Do not lie on the

ground especially if it is wet.

Employees should receive proper job instruction: Explain

to your employees how and why something is done as well as the

safest way to accomplish the task. Point out that the

safe

way is the quickest way!

Priming machine operators must always be aware of conditions

such as ditches. Proper procedures for refueling should be communicated

to workers so that an accident doesn't happen such as refueling

a hot engine with the potential for explosion.

While priming tobacco, the victim's head apparently hit the

tobacco priming machine and as a result death occurred due to

a brain hemorrhage.

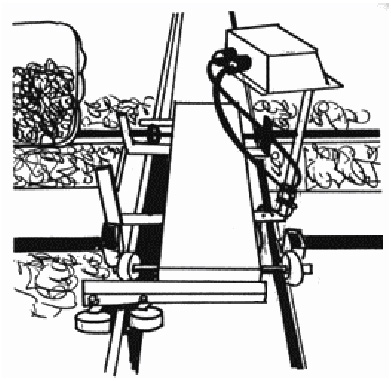

Mechanical Harvesters: Both full and semi-automatic harvesters

have their own risks. Proper instruction to the operator is

critical to safety.

Make sure that

all employees know that

only those

people you assign to operate equipment, can operate it.

The truck or tractor operator (boat driver) must be constantly

aware at all times of conditions, location of bystanders, etc.

If the driver is traveling on the roadway with farm machinery

he/she must be at least 16 years old. If they are operating

a licensed vehicle they must possess a driver's license.

The victim was driving a tractor on a highway. A truck came

up behind the tractor and attempted to pass. Without warning,

the victim started a left turn and struck the side of the truck.

The deceased was thrown from the tractor and died later in the

hospital of severe brain damage.

Establish slow down zones for the truck or tractor operator

(boat driver) and operators of other equipment in the kiln yard,

around buildings, etc. The rule for the driver should be

NO

RIDERS ON A LOADED TRUCK! Transport workers safely to

and from the field.

Consider protecting gas meters in the kiln yard to prevent

a vehicle from accidentally backing into one or hitting one.

The result could be tragic.

Use caution when moving ladders around the kiln yard.

They can contact power lines and lead to electrocution.

Be

Aware!

The teenager was working with an elevator, lowering it by turning

the crank at the side of the elevator. The elevator slipped

down and the crank continued to turn, hitting the teenager on

the head several times, resulting in death.

Check electrical cords and hookups for wear and to ensure

that insulation is intact and there is a good ground plug. Use

of ground fault circuit interrupters with electrical equipment

in the kiln yard is a good safety measure.

A ground fault

circuit interrupter protects you or your employees from

potentially fatal electric shock. Wear rubber boots in wet conditions.

Check the condition of tying machines: Pay attention

to shielding and guarding. The tying machine should always have

the wheels blocked to prevent sudden movement which could result

in injury while the equipment is operating.

When

moving equipment such as tying machines, elevators,

etc., plan the move, communicate and move slowly. Someone should

be placed in charge of moving equipment safely.

Conventional kilns should be checked for their condition,

especially tiers and kiln hanger boards. It is much easier to

replace tiers than kiln hangers.

Kiln burners should be serviced and operating properly

before they are needed. Check lines for leaks (e.g. oil spots

on the ground, pressure gauges for gas).

Bulk kilns have their own hazards: Watch for sharp edges

on racks and use care when around the pegs which can puncture

hands and fingers. Bump caps should be worn when filling the

kilns. Equipment which can swivel around should have sharp corners

removed or rounded to prevent catching the workers.

Any defective equipment at the end of harvest that you

will have to fix at a future time should be tagged. This will

act as a reminder to you that repairs should be made before

using it next year. It is easy to forget.

When unloading kilns, safety is a priority. Fast is not

always safe!

GRADING/BALING

ACTIVITIES (STRIPROOM)

Have dust masks available for employees when conditions

require them such as grading sand leaves.

Consider anti-fatigue mats on concrete floors to prevent

problems created from standing all day. The mats reduce fatigue

and sore backs.

Safe lifting techniques should be shown to and used by

all employees.

During the operation of a forklift, it is believed that the

victim was not seen by the operator and was run over by the

rear wheels.

Hot surfaces can burn. Make employees aware of hot surfaces

such as steamers and boilers.

Hand injuries are common when operating the press.

Use

caution!

It is important to make sure that their living quarters are

safe and that they are aware of potential hazards there.

Have a first aid kit on hand for workers.

Make sure a working smoke alarm is in sleeping quarters.

Mount appropriate fire extinguishers, especially near cooking

areas. For example, a multi-purpose ABC fire extinguisher.

Have Ground Fault Circuit Interrupters installed to prevent

electric shock.

Have a good ventilation fan in the cooking area.

Keep your bunkhouse safe and clean.

Check with proper authorities for regulations for housing labour

on your farm.

CAUTION: Make sure that electric generators are properly

hooked up before engaging them, AND PROPER STARTUP PROCEDURES

ARE FOLLOWED! (Check your operator's manual, or contact the

manufacturer, your retailer, or local electrician.)

DO NOT ALLOW HORSEPLAY AT ANY TIME!

A safe work environment reduces accidents and thus

STRESS

at the busiest of times.

Keep a supply of

extra equipment such as rain suits, boots,

etc., for those employees who sometimes forget to bring them.

The victim hooked a cable from a tractor driven generator to

a junction box at a hydro pole in order to provide electricity

to a barn. The victim was found between the tractor and the

generator. Investigation revealed that the cable was improperly

wired, which allowed power to cycle back to the source through

wet ground. The victim was electrocuted by touching either the

tractor or the generator.

Observe

re-entry times after spraying chemicals -- don't

send employees into recently sprayed fields.

Insist that employees wear proper footwear on the farm--

no

bare feet!

Keep

children away from the workplace! One in five deaths

on the farm in Ontario involves a child being in the workplace.

Lightning

can be a very deadly and destructive force. If you become caught

in an open area during a storm or around the farm yard, keep

these pointers in mind:

Go away from open areas; go into a building, or car/pickup truck.

Keep away from anything that conducts electricity. This includes

fences, irrigation pipes, water, faucets, appliances, etc.

Do not lie on the ground. Crouch low with your feet together

to minimize contact with the ground.

Don't be the tallest object in an area or anywhere near the

tallest object or structure.

If you must seek shelter among trees, keep away from the tallest,

crouching in a low area or ravine.

There is always a need to boost or jump-start batteries on the

farm There is great potential for injury if done improperly.

Concentrated sulphuric acid can cause severe burns.

Eye

protection is recommended when boosting the battery.

Batteries produce

combustible gas. Eliminate potential

fire starters.

It is important to connect the cables in the following order:

- Positive (red) terminal to the dead battery.

- To positive (red) terminal of the good battery.

- Negative terminal of the good battery.

- To engine block of stalled vehicle, away from

the battery.

- Start the vehicle with the good battery first, then

start the stalled vehicle. Cables should be removed in reverse

order from 4 through to 1. which could cause sparking as

a result of electrical contact.

Each worker when starting a new job should receive some training

for the task that they will be doing. Even those who claim to

be

experienced at a job should be monitored to make sure

that they are doing the job correctly and safely.

The following are the basics that should be considered when

training workers:

Explain how and why you want a particular job done.

Personally demonstrate how to do the job, the right way.

If the

job has hazards, make certain that they are pointed

out.

Before leaving workers on their own, make sure that they

can

demonstrate to you how to do the your way, and do

not leave the workers until you are certain that they will do

it right.

Make

frequent checks on new workers!

BE A GOOD MANAGER!

ARE YOU

READY FOR AN EMERGENCY?

POST EMERGENCY TELEPHONE NUMBERS by each telephone on

the farm. You should include police, ambulance, fire, doctor,

hospital, neighbors etc.

USE 911 WHERE AVAILABLE.

Make sure that you post the

FARM LOCATION number where

available and the county road, township, lot and concession.

You may also want to have a short description of how to get

there from the main roads. Remember, in an emergency, it is

hard to think straight, and easier to read directions.

What do you tell to

EMERGENCY PERSONNEL? Describe the

emergency in detail and how to get to the location of the emergency.

Make sure that you give the telephone number that you are calling

from.

STAY ON THE PHONE until you are told to hang up.

DO YOU HAVE FIRE EXTINGUISHERS in key locations on the

farm such as bunkhouse, strip room, workshop, kiln yard, tractors,

etc.? Does everyone know how to use them?

Has anyone on your farm taken

FIRST AID TRAINING COURSES?

Do you have first aid kits at work locations?

Make sure your first aid kit contains

latex gloves, for

administering first aid.

The FARM SAFETY ASSOCIATION has information on many safety topics

and can assist you in developing a safety plan for your farm.

Disclaimer and Reproduction Information: Information in

NASD does not represent NIOSH policy. Information included in

NASD appears by permission of the author and/or copyright holder.

More