To know how to correctly use jacks for equipment repairs.

Serious crushing accidents can result from the improper use of jacks. Demonstrate

the correct way to use a jack when working on equipment. Let teams of workers practice the

correct method for using a jack with various pieces of equipment.

The following recommendations are important for the safe use of jacks. Compare the rated capacity of

the jack to the weight of the load to be lifted to ensure that the jack can safely do the job. Keep jacks

lubricated as recommended. Do not use a jack that is leaking fluid.

Handle jacks carefully. Dropping or throwing them may distort or crack the metal, and the jack may

fail under the load. Position the jack properly at a point that can carry the lifted weight.

The lift point should be flat, level with the floor or the ground, and able to support the base of the jack.

Lift should be straight up and down. If working on the

ground, place a long wide block under the base of the

jack to keep it from sinking, shifting or tipping when

weight is applied. If the jack will not lift high enough,

place additional blocking under the jack. Never put extenders

for height between the jack saddle and the load.

Stabilize the equipment. If the machine is self-propelled,

place the transmission in gear or in the park position,

and set the brakes. Block at least one of the wheels remaining

on the ground. When lifting pull-type equipment,

hitch it to a tractor drawbar to keep it in place.

Always check the position of the jack after it has started

to lift. If it leans, lower the jack and reset. Lift no higher

than is necessary. Beware of the jack handle. Some

mechanically operated jacks can pop up and kick when

the load is lifted or lowered. Stand to one side while

jacking equipment to avoid being struck by the handle.

Never straddle a jack handle and always remove the

handle when it is not being used.

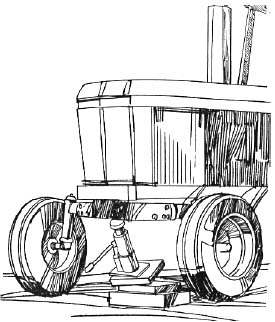

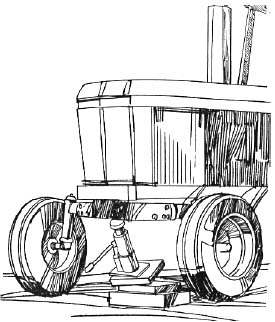

Avoid this happening! Reset the jack

if it starts to lean,

and block the equipment

more securely.

Support the load that is being jacked with blocks or stands. Never allow raised equipment to remain supported by jacks alone. Jacks can fail and tip, causing the equipment to fall unexpectedly. Place solid blocks or stands under the equipment immediately. Do not use cement or cinder blocks because they may shatter under the load.

When Using Jacks:

- Stabilize equipment, then set brakes and/or block wheels.

- Do not overload the jack.

- Lubricate with recommended oil as directed.

- Do not drop the jack.

- Discard damaged jacks.

- Position the jack properly and discontinue lifting if the load shifts.

- If working on the ground in the outdoors, place a heavy block under the base of the jack.

- Recheck the jack before completing the lift.

- Remove jack handle when lift is completed.

- Lift only as high as necessary.

- Support the lifted load with blocks or a stand.

- Check jack before use to ensure that it can carry the load.

- Do not use leaking jacks.

- Stand to the side while jacking to avoid being struck by the handle.

- Support load with blocks or stands.

- Cement or cinder blocks should not be used because they may shatter under the load.

True or False

| 1. Dropping and throwing jacks may distort or crack the metals causing the jack to fail under the load. |

T |

F |

| 2. Always place the vehicle in park and set the brakes before jacking. |

T |

F |

| 3. Do not check or adjust the jack position once it has started to lift the weight. |

T |

F |

| 4. Support the load that is being jacked with blocks or stands. |

T |

F |

| 5. A cement or cinder block should be used to block and support the machinery during the lift. |

T |

F |

Answer Key

1. T, 2. T, 3. F, 4. T, 5. F

Disclaimer and Reproduction Information: Information in

NASD does not represent NIOSH policy. Information included in

NASD appears by permission of the author and/or copyright holder.

More