When you operate a tractor and other farm equipment on public roads,

you must obey all traffic rules. When pulling an implement that blocks

your view of traffic, ask another worker to escort you with a truck with

flashing lights. An escort warning other drivers is especially important

around bayous and turns where trees grow up near the road and on heavily

traveled roadways.

When you operate a tractor and other farm equipment on public roads,

you must obey all traffic rules. When pulling an implement that blocks

your view of traffic, ask another worker to escort you with a truck with

flashing lights. An escort warning other drivers is especially important

around bayous and turns where trees grow up near the road and on heavily

traveled roadways.

Make sure no one is passing before making a left turn. Turning left is

particularly dangerous if a driver attempts to pass you from behind at a high

speed. Look again, just before you

turn, to avoid a serious crash. If

necessary to be able to see behind

you, slow and pull over to the right

road shoulder, then cut back

sharply; look for passing and

oncoming traffic before pulling into

the  left lane. Fasten a "Slow Moving Vehicle" emblem securely to the rear. Keep the emblem and flashing lights clean and bright.

left lane. Fasten a "Slow Moving Vehicle" emblem securely to the rear. Keep the emblem and flashing lights clean and bright.

Don't speed. Towed equipment can "fish tail" or swerve back and forth. Extra weight on the toolbar may cause you to lose control of the tractor and crash or turn over. Poorly hitched equipment can come loose and crash into other people or vehicles. If implements swing from side to side, you are traveling too fast! Slow down using gradual braking to regain control.

Hard braking often whips the trailed implement forward like a jack-knifed trailer truck. A tractor should never tow a trailer or other trailed implement weighing more than the tractor.

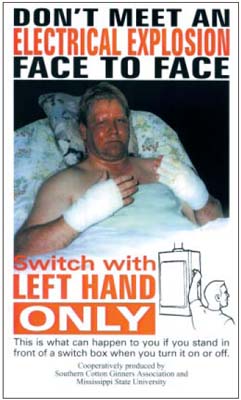

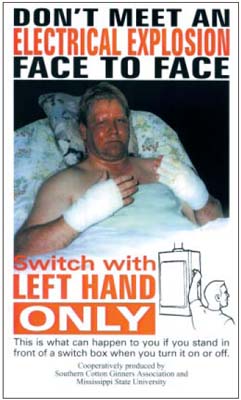

Electricity burns as it

enters the body and may

tear flesh as it leaves. The

human body is a better

conductor of electricity

than air, tires, soil, grass or

trees. Electricity will take

the easiest path to the

ground which could be

through your body. Know

what you are doing, be

purposeful, always being

very cautious when

working around power lines

or any electrical wires.

Live Power Lines

High voltage power lines are extremely dangerous. Make sure that you maintain at least 10 feet of clearance when working near or passing under power lines. This is a federal law that is for your safety. If you are unsure of power line clearance, always ask a helper, standing where he has a good angle to judge whether clearance is adequate, to guide you.

Do not leave the boom truck or tractor if it contacts a live wire. Move the vehicle or equipment out of contact with the electric wire if it isn't hooked. Never move electric lines with a pipe or pole. Wood and PVC pipe will conduct electricity, especially when damp and dirty.

Tires may be the only insulator that prevents you from becoming electrocuted.

Do not step down to the ground. Don't touch the soil and the equipment at the same time or you may be electrocuted.

Leave only if the equipment is entangled in the electric lines and a fire or explosion is likely. The only acceptable escape is to jump clear of the vehicle, landing with your feet equally far from the vehicle, or if possible, jump and roll away from the equipment.

Downed Power Lines

Always assume downed power lines are hot. Soil can transmit voltage

and you can be electrocuted by a downed "hot" wire without even touching it. Stay at least 20 feet from a downed wire.

Call your electric supplier to disconnect power and fix downed lines or storm-damaged transformers and service entrances before working near them.

If you are in a pond when a power line is contacted or knocked down, leave the pond immediately and remain as far away from the line as possible.

Always report broken or poorly insulated wires to your supervisor or an electrician. If in doubt about electrical circuit safety, turn off the electricity or disconnect the circuit breaker controlling the line. Always make sure that all circuits and equipment you are using are properly grounded and in good working order.

Damaged Power Lines & Wires

Lightning often damages outside electric control devices and motors. Many times there will be no apparent damage visible to the outside of the device, yet the control box or motor may be energized and/or shorted, posing a serious electrical shock. Always be extra cautious following lightning storms and test with a circuit tester before touching a control box.

Equipment used to cut grass and weeds may also destroy ground wires. If you have doubts about a control box, contact your supervisor.

Always make sure the electricity is off at the circuit breaker and padlocked before entering the pond to work on electric wires, pumps or aerators. Never assume the electricity is off. Make a check with a circuit tester before beginning other maintenance. If an electric motor doesn't start, notify your supervisor immediately or call an electrician.

Never disengage and hold the clutch with the engine running and

transmission in gear. Before starting a tractor engine where any co-workers

may be near, sound out a loud "CLEAR?" and wait a few seconds for a response from anyone who may be out of visibility. Do the same before raising or lowering implements or moving the tractor if other workers may be present.

Do not operate machinery without first replacing all power takeoff, or PTO, guards and shields following maintenance. Make sure rolling PTO shields have not been damaged and operate freely. If equipment was delivered without proper shielding, you can sometimes construct relatively inexpensive shields out of sheet metal or pipe. The time and expense is well worth the knowledge that someone will not get caught in a sprocket and chain, belt and sheave or a revolving shaft.

Do not operate machinery without first replacing all power takeoff, or PTO, guards and shields following maintenance. Make sure rolling PTO shields have not been damaged and operate freely. If equipment was delivered without proper shielding, you can sometimes construct relatively inexpensive shields out of sheet metal or pipe. The time and expense is well worth the knowledge that someone will not get caught in a sprocket and chain, belt and sheave or a revolving shaft.

Setting an aerator is the only time you should leave the tractor seat while the PTO is engaged.

Always put the tractor in park, lock both brakes, and if necessary, put substantial blocks behind the rear wheels when parking it. When you dismount, stay well clear of a powered aerator; walk around the front of a tractor, not the back. Never try to cross over a rotating PTO shaft! The route around the front of the tractor is much shorter than a trip to the hospital or funeral home.

Remember - do not get too close to a moving PTO shaft. Your clothes can get caught and cause a serious, permanent injury!

Many people are killed or

seriously injured each year when

run over by tractors or equipment.

A driver or rider may slip and be

run over by his tractor and

crushed or cut up by a disc or

mower. A victim is often in the

driver's blind spot and may be run over. Or you may start a tractor that someone unintentionally left in gear and be run over and crushed.

Many people are killed or

seriously injured each year when

run over by tractors or equipment.

A driver or rider may slip and be

run over by his tractor and

crushed or cut up by a disc or

mower. A victim is often in the

driver's blind spot and may be run over. Or you may start a tractor that someone unintentionally left in gear and be run over and crushed.

A driver need only use common sense and safe driving practices to prevent these accidents.

- Wear your seat belt.

- Never allow passengers.

- Start the tractor only from the seat. If it won't start from the seat, make repairs.

- Never try to start a tractor by bypass starter or jump-starting without an operator in the seat.

Never remove a roll-over protective structure, seat belt, lights or other safety devices.

Removing safety devices could result in an accident and cause injuries or potential lawsuits. Some ROPS telescope or fold to allow operation inside of low-ceiling buildings and under limbs. If it is necessary to fold a ROPS, always return it to its upright position immediately when that operation is completed.

When approaching an operating tractor, approach from the front and side at about a 45 degree angle to the direction of travel so that the operator can see you. Never approach through tall weeds or from behind equipment that obstructs the operator's view. Stand beside the rear wheel when talking to the operator; never in front of or behind the wheels, between the tractor and implements or between the wheels.

If you are approached while operating a tractor, stop the tractor, disengage power to and lower any implements that you are operating, place the tractor in park or neutral and stop the engine.

|

|

Incorrect jump start: Driver not in seat. |

Correct jump start: Driver seated, with foot on brake. |

Distribution and circuit breaker boxes are extremely dangerous when

hot. Power may be available at 120, 240 or 480 volts.

Waders or farm boots and rubber gloves will not insulate you from those

voltages.The contacts can arc and flash with enough force to blow the door

off the box and burn your face.

Make it a habit

to stand off to the

side of the box,

facing away from

it, and switch the

power on or off

with the hand

nearest to the

power disconnect

on the box.

Be especially

careful when

moving tall ladders,

pipes, antennas and

other objects

around overhead

power lines.

Disconnect

electrical power

and locate buried

lines before digging.

Any electrical

cables near or

below ground level

should be inside

electrical conduit

for their protection.

Never use

temporary cables

that are not

protected with

conduit.

Always be careful not to damage equipment or break a ground when

cutting grass and weeds near power poles, ground and guy wires. Never try

to drive or mow over an electric cord or line, unless it is protected in

conduit and buried to a sufficient depth.

Operations become more hazardous at night. Vision and judgment may

be poor. Stay off narrow, slick levees at night. Become familiar with feeding

levees and the best pond access routes during the day. Check all lights at the

shop before dark. All tractors need good rear and front lights in order for

one person to safely move equipment and spot aerators at night. When

possible, work in pairs when moving aeration equipment at night.

If you are having problems, don't wait - GET HELP!

Practice backing aeration equipment into the pond during the daytime until you can do it well. When backing an aerator into a pond at night be sure to:

- Use the tractor lights and, if possible, have someone assist with a hand-held light.

- Go slowly to make sure you do not damage the drive shaft.

- Position the tractor with the PTO shaft joints as straight as possible.

- Put the tractor in park and apply the brakes.

- Idle the tractor down, engage the PTO and slowly increase the throttle until the aerator is turning at the proper speed.

- Do not get too close to a moving PTO shaft. Your clothes can get caught and seriously injure you!!

It is always a good idea to keep extra lights, chains, booster cables, a mobile phone and first aid supplies in your truck.

Do not be in a hurry! Go slow, arrive safely and complete your task.

|

| Nighttime operation in bad weather can result in serious accidents like the one above. |

Routines to Stay Alert

Get plenty of sleep when not on the job. Drink hot drinks, take

frequent breaks, walk or exercise to keep alert and awake during night work

periods.

When possible, use the buddy system and establish regular check points.

It is always best to check regularly with someone working elsewhere on the

farm or at home. Know the procedure and who to call for extra help during

critical times.

Mobile phones and radios are for business. Don't tie up a means of communication with personal or frivolous chatter!

If tall grass must be cut on the slope away from the pond, choose a slow

gear first and then continue, driving slowly while watching ahead for holes,

ditches and obstacles.

Tractors can pull heavy loads without a backward overturn - if used properly. Always hitch to the drawbar and keep it at the height recommended by the manufacturer. When the hitch point on a tractor is too high, the risk of rear overturn is great.

If equipment gets stuck or the front end of the tractor begins to leave the ground, stop until sufficient front weights are added! The tractor can flip backwards in less than three-fourths of a second.

Never stand between a tractor and implement while the driver backs up to hitch. The slightest distraction - a foot slipping on the clutch or brake pedal or a jerky clutch - may cause you to be run over or crushed.

Before hitching to the tractor's 3-point hitch, ensure that the lift arm extensions are working well. Before hitching, adjust the stationary drawbar to the short, high position, swing it to the extreme left side and pin it in place. Align the tractor squarely with the implement to be hitched. Back the tractor so that the lift ends are within 2 to 3 inches of the implement hitch pins. Raise or lower the lift arms and adjust the lift height with the lift adjustment crank as needed for good alignment. Release the lift arm telescoping locks, extend the lift arm extensions and fasten both swivel ball sockets to the implement with the proper pins. Back the tractor while raising and lowering the hitch until the lift arm extensions lock firmly in the operating position. Then attach the top link, adjusting its length to attach the implement.

Always use hardened hitch pins of the correct size and secure them with quick lock pins, not bolts or wire that may break or slip out! Don't forget to return the jacks and jack stands to a safe position for operating the implement.

Reverse this procedure for unhitching. Never lift or drag an implement by hand in order to hitch or unhitch the tractor. Always use implement jack stands and tongue jacks to keep the implement in the proper position for easy hitching and unhitching. If the implement does not have jack stands built in, set the implement on good solid wooden blocks when unhitching.

If a tractor

begins slipping

sideways or feels

unstable on a

pond bank, turn

toward the

bottom of the

slope. A sliding

tractor can

suddenly hit a

hole or abruptly

regain traction

and turn over.

Steering in the direction the tractor is moving will regain control. It is

better to nose a tractor into a pond than turn it over in water.

Avoid overturns by driving forward down a steep grade or levee. Back

the tractor up steep slopes to prevent rearing and flipping the tractor

backwards. Remember that 3-point hitched implements change the balance

of the tractor. If the front end is light, add weights to improve control.

Stay off slopes too steep for safe operation. If available, use a tractor with

a wide wheel base and dual wheels. When mowing levees, set wheels as wide

as possible and start on the levee, working toward the pond bank.

Do not cut where you cannot see. If there are spots that may hide a hole

or unstable bank, walk and inspect the area, flagging dangerous sites before

mowing. Pond banks may cave in from the tractor weight, especially when

passing over animal burrows or areas where wave action has undercut

the bank.

Keep your tractor

away from the edge

of the pond. Sidemounted

rotor or

sickle bar mowers are

best for cutting grass

near pond edges or

on slopes away from

the pond. Watch for

holes or ruts caused

by erosion in the

tractor path.

A good rule of thumb is to keep the tractor a distance of at least the

depth of the ditch or pond away from the edge of the bank or water. With

the mower extended, the weight of the tractor can be kept a safe distance

from an unstable bank or steep slope.

Whenever it is possible, cut slopes with a side-mounted mower, keeping

the mower on the uphill side. Bumps or unused equipment hidden in grass

may cause an overturn if the upslope wheels strike them.

Do not use drugs or alcohol

during work hours. If you must use

prescription drugs, notify

your manager so he understands

your needs and limitations and

supports you.

Working around a seine reel

tractor can be dangerous. The

tractor must be backed and

repositioned often. All crew

members should be alert to assure

that the driver does not back over

or into someone. Keep hands and

arms clear of the net and reel while

pulling in the seine. You could

easily get caught and pulled into

the reel or crush your hand or arm

between the reel and its metal frame.

Always set the truck up on dry, level ground. Place thick oak blocks

under each outrigger and put the outriggers down prior to swinging the

boom off the truck.

When working in the loading area, always wear a hard hat! Never stand

under or in the path of the boom while loading. The boom could break,

dropping the boom, basket, scales and fish.

The loading basket door can come open dropping the 1,200 to 2,400

pounds of fish on workers below. The basket might swing into workers on

the ground. Workers

dumping the basket into

the hauling truck can be

knocked off the truck.

If you are working a

critical job like dumping

the basket into the truck

or filling the basket in

the pond, arrange hand

signals with the boom

truck operator to permit

good communication.

Do not distract the

operator with unnecessary signals or horseplay.

Keep the boom truck in good operating shape.

Keep the tires properly

inflated, check the hydraulic oil and lines regularly and check the boom and

truck bed for signs of strain such as fractured paint, hairline cracks or bows.

Report any unsafe conditions to your supervisor.

Serious boating accidents can occur during fish harvesting.

Never place your hands between the boat and net when pushing on the

seine with the boat. Always shut the motor off when untangling net from

the propeller.

Accidents often occur as boats are loaded onto trailers. Your fingers,

hands, legs or back can be injured if you stand by the trailer trying to pull a

moving boat up to the winch. Select a position where your footing is firm.

Don't climb on the boat trailer frame while loading a boat. Wet grass and mud become slick, resulting in serious injury when you slip and fall.

Every new boat operator should be taught boat and motor safety before being allowed to run a boat during harvesting. Never refuel a hot engine. Extinguish all cigarettes before handling gasoline. Clean up any gasoline spills immediately for your safety.

Always keep the boat and motor clear of other workers who may be in the water. If you fall out of the boat, do not panic, remember that the pond is only 3 to 5 feet deep!

Catfish barbs can cause

serious injuries.

Handle fish carefully. Do

not kick a fish back into the

pond or off a truck. Barbs can

pierce your shoe or boot and

lodge in your foot. Because

catfish fins have serrated edges,

they are difficult to remove

and can leave large lesions.

Fingerlings have small,

sharp fins that break off easily

like a wood sliver. Removal

may require minor surgery. If

left untreated, they can cause

serious infections, including

blood poisoning.

If you get stuck, remove

the fin as soon as possible,

wash the wound with soap and

water and apply a disinfectant.

See a doctor if you have any

swelling, fever or other

symptoms of infection.

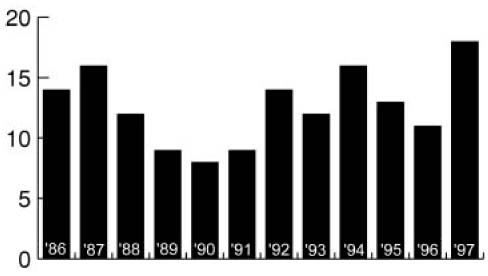

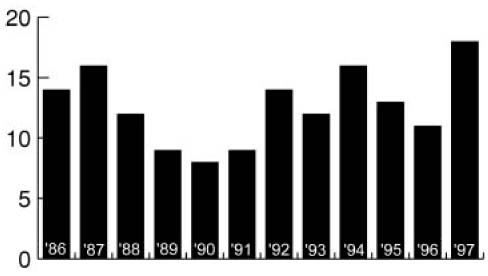

Many farmers are killed or injured in tractor accidents each year.

Improper operation of a tractor or equipment causes most of the accidents.

The most important point of tractor safety is to know your tractor. Know

how the tractor handles and be alert to avoid an accident. Always drive at a

moderate speed and pay attention to what you are doing and where you

are going.

Mississippi Tractor Deaths 1986-1997

To avoid accidents, less-experienced drivers should get training in safe

practices from more-experienced drivers. Always ask questions if you are not

sure. If you are not familiar with the operation of a machine, say so! Select a

good, safe, experienced driver to imitate and work hard to eliminate bad

driving habits. Remember, your life and limbs are at risk!

Tractor overturns are the leading cause of fatalities and serious injuries.

All tractors used on fish farms should have roll-over protective structures

(ROPS or roll-bars) and seat belts. You should always fasten your seat belt

when using a tractor with a roll-bar. Don't use a seat belt if the tractor doesn't have a roll-bar.

Fish farm workers must be particularly careful mowing levees, driving in and out of ponds or ditches, working close to ditches or pond banks and making fast turns. Doubling your forward speed increases your chance of overturning four times.

Each year fish farm workers have serious accidents, resulting in

equipment damage, injuries and even death. These accidents often involve

tractors and machinery; electric shock and burns; feeding, harvesting and

handling fish; pond levee maintenance and night and limited visibility

operation.

Carelessness is the No. 1 cause of farm accidents. Many accidents occur

when a risky task is attempted because "I am good enough to get away with it." You may get away with it - most of the time. The time you don't may cost you your life or limbs. Taking such chances, even if you are very good at what you do, is not worth the risk to you or to your employer. Even if you don't get hurt, a co-worker may copy your actions and be injured.

Most accidents can be prevented if you will take a few seconds to think about the whole task, plan your actions, get needed equipment or help and exercise good judgment every day.

Mower blades, PTOs, fans, chains, gears, belts and other moving parts

can be very dangerous.

Hands, fingers, hair and loose-fitting clothes can snag and pull you

along into the machine with them. Pinch points of gears, chain and V-belt

drives, rollers, crimpers and augers are fast, powerful and may be impossible

to stop once you get caught.

You can easily lose a limb or your life. Always stop the equipment, lower

it and kill the engine to avoid contact with moving parts or pinch points.

Always replace shields after removing them for maintenance.

Batteries can explode in your face. Charging and discharging a lead-acid

battery generates hydrogen and oxygen gas. It can be very explosive,

especially in a confined area where hydrogen gas can reach an explosive

concentration. A spark can cause an explosion that ruptures the battery and

sprays acid. Never use an open flame for a light source near a battery

because it might cause an explosion.

If battery acid splashes on you, flush your skin or eyes with plenty of

water. See a doctor.

When removing the battery, always disconnect the grounded terminal

first. When replacing the battery, connect the grounded terminal last.

Always turn a battery charger off before connecting or disconnecting it from

a battery.

Never short across battery terminals. Remember "Red Is Positive" on all automotive equipment. If in doubt about the polarity of the post, look for a "+", red cable or the larger of the two posts.

When boosting a battery, connect first to the positive

terminal of the charged battery; then connect the other end of the booster cable to the positive terminal of the battery to be boosted. Then, connect to the negative terminal or the equipment frame of the vehicle with the charged battery, followed by the last connection to the equipment frame of the vehicle with the battery to be boosted. Allow the battery to charge for a few minutes before attempting to start the engine.

Once the engine is operating, disconnect the booster cables in the reverse order; ground first, followed by the positive cable. Never allow cable clamps to contact each other if they are connected to a battery.

Scalding and

severe burns can

result from taking

the cap off a hot

radiator. Always

allow radiator

liquid to cool first.

Place several layers

of thick cloth over

the cap, stand to

the side and

slowly turn the

cap until pressure

begins to escape.

After pressure is

released, you can safely remove the cap.

Remove or relieve the pressure from hydraulic system components

before servicing them. Never break a hydraulic coupling or line while it is

under pressure.

Use a piece of cardboard or stiff paper to check for leaks by holding near

the suspected line or fitting. Do not use your hand. High-pressure hydraulic

oil may be injected under the skin and could result in the loss of the hand.

Prolonged exposure to hydraulic oils, gasoline or diesel fuels may cause

skin irritations and rashes. Always wash with soap and water or a good hand

cleaner on any areas of skin that might come in contact with petroleum

products.

When the outer coating on a hydraulic hose becomes damaged, replace

the hose. Hose failure will probably soon follow.

Think about what you are about to do. Try to anticipate dangerous

situations and take precautions to avoid an accident.

Well-maintained equipment is more dependable, lasts longer and is safer

to operate. Always check tires for breaks, knots and proper inflation.

Blowing a tire at high speed is dangerous.

Check oil, fuel and water levels and bring each up to proper operating

levels prior to starting the equipment.

The front end should not shake when a tractor is driven. If wheel

bearings, ball joints or steering arms are worn, a loss of control, or possibly,

a wreck, could occur. Check the wheel lugs periodically to be sure all are in

place and tight. If you must repair a piece of equipment, especially in the

field, be very careful and don't rush.

Consider ways to avoid serious accidents while servicing equipment.

- Before servicing, disengage electric power to paddle wheels, pumps, feeders and other equipment. Shut off the engines and disconnect PTOs when greasing or servicing.

- Use a lock on the electric disconnect or lock the tractor cab. Place the tractor key in your pocket to prevent anyone from accidentally powering equipment on which you are working.

- Lower any equipment, such as mowers, backhoe buckets and aerators to the surface so it cannot accidentally fall and crush someone. When handling heavy objects, wear steel-toed shoes.

- Use gloves to protect your hands from fish, heavy cables, sharp, rough or hot objects. Keep your work area clean and clear of obstructions, water or other liquids to prevent falls.

- Protect your eyes. Always wear shatterproof safety glasses when grinding, welding, cutting or using hammers, punches, chisels or power tools. When working around engines, blowers, guns and hammers, wear ear plugs to protect your ears from loud noises.

- When using compressed air through a blow nozzle or operating pressure washers or steam cleaners, wear safety glasses. Never direct compressed air or pressurized and/or heated water against your skin or in the direction of your eyes and ears.

Improper use of jacks or the use of undersized jacks can cause crushing

injuries or death. Handyman jacks are very useful and very dangerous. They

can lift very heavy equipment which is low to the ground, but the handle

can spring back and strike you in the face or head, causing serious injury.

Equipment being raised can suddenly slip

sideways off a jack.

Check hydraulic capacity and the

weight of the machine. If the jack has the

lifting capacity, position the jack under the

machine on a thick piece of wood resting

on a solid footing. If the jack leans or the

equipment shifts, let the jack down slowly

and start again. Lift no higher than

necessary.

Put jack stands under the equipment as

soon as it is raised to the desired height.

Sometimes it is wise and possible to use a

jack stand or blocks to crib as you lift the

equipment. Never leave equipment

supported by jacks alone. Never work under equipment that has not been

securely blocked, even equipment that is raised on a hitch.

Hoists also can be very dangerous. Overloading a hoist or failing to

secure the lifting chain to keep it from slipping are two common hoistrelated

accidents.

Use a grade 80 or System 10 alloy chain of adequate strength to lift the

load for overhead lifting. Chains with deformed, stretched or welded links

are not suitable for lifting.

Chain hooks should also match the chain's strength. Avoid using cables with clamps for lifting or towing. Never twist or knot a chain to take up slack.

Use a spreader bar to keep chains pulling in a straight line with the load and hoist. Don't overload the hoist. If possible, use a chain hoist instead of a cable "come-along." Keep your hands clear. Stand aside as you raise the equipment. Never stand under hoisted equipment unless it is securely blocked or on stands.

Remember: Be careful, be alert, be

thoughtful, and above all, be safe!

PREPARED BY

C. Douglas Minchew, Assistant Fishery Biologist

Mississippi State University

Thad Cochran National Warmwater Aquaculture Center

Stoneville, MS

MAJOR FUNDING PROVIDED BY

USDA/Cooperative State Research, Education

and Extension Service

PARTICIPATING UNIVERSITIES AND

GOVERNMENT AGENCIES

Mississippi State University

Thad Cochran National Warmwater Aquaculture Center

Stoneville, MS

Aquaculture/Fisheries Center

University of Arkansas, Pine Bluff

Cooperative Extension Service, Auburn University

Cooperative Extension Service, Texas A&M University

Cooperative Extension Service, University of Arkansas

U.S. Dept. of Agriculture, Southern Regional

Aquaculture Center

INDUSTRY PARTNERS

Catfish Farmers of America

Aquacenter, Inc. - Leland, MS

Arkansas Bait and Ornamental Association

Arkansas Farm Bureau

Entergy Corporation

Farm Equipment - Portland, AR

National Aquaculture Association

Southern Aquaculture

Supply - Lake Village, AR

The primary purpose of this booklet is to encourage those working on fish farms to work safely. Hopefully, we have provided information on many safety risks and methods of risk reduction. This booklet is not intended to be all-inclusive, but rather to highlight those practices which are responsible for most of the deaths and serous injuries around fish ponds. We hope that farm owners and managers find this booklet useful in working with their employees to help develop an effective safety program on their fish farms.

-

C. Douglas Minchew

Disclaimer and Reproduction Information: Information in

NASD does not represent NIOSH policy. Information included in

NASD appears by permission of the author and/or copyright holder.

More

When you operate a tractor and other farm equipment on public roads,

you must obey all traffic rules. When pulling an implement that blocks

your view of traffic, ask another worker to escort you with a truck with

flashing lights. An escort warning other drivers is especially important

around bayous and turns where trees grow up near the road and on heavily

traveled roadways.

When you operate a tractor and other farm equipment on public roads,

you must obey all traffic rules. When pulling an implement that blocks

your view of traffic, ask another worker to escort you with a truck with

flashing lights. An escort warning other drivers is especially important

around bayous and turns where trees grow up near the road and on heavily

traveled roadways.

left lane. Fasten a "Slow Moving Vehicle" emblem securely to the rear. Keep the emblem and flashing lights clean and bright.

left lane. Fasten a "Slow Moving Vehicle" emblem securely to the rear. Keep the emblem and flashing lights clean and bright.

Do not operate machinery without first replacing all power takeoff, or PTO, guards and shields following maintenance. Make sure rolling PTO shields have not been damaged and operate freely. If equipment was delivered without proper shielding, you can sometimes construct relatively inexpensive shields out of sheet metal or pipe. The time and expense is well worth the knowledge that someone will not get caught in a sprocket and chain, belt and sheave or a revolving shaft.

Do not operate machinery without first replacing all power takeoff, or PTO, guards and shields following maintenance. Make sure rolling PTO shields have not been damaged and operate freely. If equipment was delivered without proper shielding, you can sometimes construct relatively inexpensive shields out of sheet metal or pipe. The time and expense is well worth the knowledge that someone will not get caught in a sprocket and chain, belt and sheave or a revolving shaft.  Many people are killed or

seriously injured each year when

run over by tractors or equipment.

A driver or rider may slip and be

run over by his tractor and

crushed or cut up by a disc or

mower. A victim is often in the

driver's blind spot and may be run over. Or you may start a tractor that someone unintentionally left in gear and be run over and crushed.

Many people are killed or

seriously injured each year when

run over by tractors or equipment.

A driver or rider may slip and be

run over by his tractor and

crushed or cut up by a disc or

mower. A victim is often in the

driver's blind spot and may be run over. Or you may start a tractor that someone unintentionally left in gear and be run over and crushed.

Distribution and circuit breaker boxes are extremely dangerous when

hot. Power may be available at 120, 240 or 480 volts.

Distribution and circuit breaker boxes are extremely dangerous when

hot. Power may be available at 120, 240 or 480 volts.

Tractors can pull heavy loads without a backward overturn - if used properly. Always hitch to the drawbar and keep it at the height recommended by the manufacturer. When the hitch point on a tractor is too high, the risk of rear overturn is great.

Tractors can pull heavy loads without a backward overturn - if used properly. Always hitch to the drawbar and keep it at the height recommended by the manufacturer. When the hitch point on a tractor is too high, the risk of rear overturn is great.  Operating

on Slopes

Operating

on Slopes Stay off slopes too steep for safe operation. If available, use a tractor with

a wide wheel base and dual wheels. When mowing levees, set wheels as wide

as possible and start on the levee, working toward the pond bank.

Stay off slopes too steep for safe operation. If available, use a tractor with

a wide wheel base and dual wheels. When mowing levees, set wheels as wide

as possible and start on the levee, working toward the pond bank.

Working Safely

Around

Seine Reels

Working Safely

Around

Seine Reels The loading basket door can come open dropping the 1,200 to 2,400

pounds of fish on workers below. The basket might swing into workers on

the ground. Workers

dumping the basket into

the hauling truck can be

knocked off the truck.

The loading basket door can come open dropping the 1,200 to 2,400

pounds of fish on workers below. The basket might swing into workers on

the ground. Workers

dumping the basket into

the hauling truck can be

knocked off the truck. Handling

Catfish

Handling

Catfish

Each year fish farm workers have serious accidents, resulting in

equipment damage, injuries and even death. These accidents often involve

tractors and machinery; electric shock and burns; feeding, harvesting and

handling fish; pond levee maintenance and night and limited visibility

operation.

Each year fish farm workers have serious accidents, resulting in

equipment damage, injuries and even death. These accidents often involve

tractors and machinery; electric shock and burns; feeding, harvesting and

handling fish; pond levee maintenance and night and limited visibility

operation.

terminal of the charged battery; then connect the other end of the booster cable to the positive terminal of the battery to be boosted. Then, connect to the negative terminal or the equipment frame of the vehicle with the charged battery, followed by the last connection to the equipment frame of the vehicle with the battery to be boosted. Allow the battery to charge for a few minutes before attempting to start the engine.

terminal of the charged battery; then connect the other end of the booster cable to the positive terminal of the battery to be boosted. Then, connect to the negative terminal or the equipment frame of the vehicle with the charged battery, followed by the last connection to the equipment frame of the vehicle with the battery to be boosted. Allow the battery to charge for a few minutes before attempting to start the engine.  Check hydraulic capacity and the

weight of the machine. If the jack has the

lifting capacity, position the jack under the

machine on a thick piece of wood resting

on a solid footing. If the jack leans or the

equipment shifts, let the jack down slowly

and start again. Lift no higher than

necessary.

Check hydraulic capacity and the

weight of the machine. If the jack has the

lifting capacity, position the jack under the

machine on a thick piece of wood resting

on a solid footing. If the jack leans or the

equipment shifts, let the jack down slowly

and start again. Lift no higher than

necessary.