The power take-off (PTO) drive, found

on most farm tractors, is a major power

source for agricultural equipment. The

PTO system efficiently transfers

mechanical power from the tractor to the

implement, but it may present serious

hazards to persons who are unfamiliar

with its operation.

PTO Components

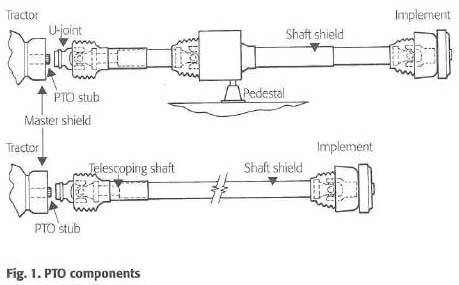

When hooked up to a piece of

equipment, the complete PTO system or

implement input driveline may connect

either directly to the tractor spline or stub, or indirectly through a

pedestal connection as illustrated in

figure 1. Coupling devices are used to

attach the shaft to the tractor and to the

implement.

A spline collar slides over the tractor's

spline, which extends from the tractor

differential. The collar is held in place by

a spring-loaded pin that latches into a

recess on the spline. The telescoping

feature of the shaft allows the collar to

slide easily onto the spline. Together with

the universal joints, the telescoping shaft

allows the PTO system to flex and adjust

when the tractor turns or travels over

uneven terrain.

When operated at full recommended

speed, a PTO shaft will rotate clockwise

at 540 revolutions per minute (rpm),

which equals 9 revolutions per second, or

at 1,000 rpm (16.7 revolutions per

second). As shown in the Table 1, a 540

rpm shaft travels 7.1 feet per second,

while a 1,000 rpm shaft turns 13.1 feet

per second. A person caught in a

revolving PTO shaft has little chance to

escape.

Shielding

Shields are essential to the safe

operation of the PTO system. To prevent

operators from coming in contact with

spinning parts, every component of the

PTO system should have guards,

including a shaft shield, a master shield,

and an implement shield.

Most modern shaft shields are tubular,

although older equipment may have

inverted U-shaped shielding devices.

Tubular shields are recommended

because U-shaped shields

guard against contact only from the sides

and top of the shaft. Metal or plastic

tubular shields completely enclose the

shaft. Bearings prevent the shield from

spinning when contact is made. Some

models use a chain connected to a

stationary part of the machine to prevent

the shield from spinning constantly. Even

if tubular guards are in place, a hazard

may exist if the shield is damaged and

cannot spin independently from the shaft.

A damaged guard can be as hazardous

as an unguarded shaft.

The tractor's master shield and the

implement shield are particularly

important because they prevent

equipment operators from getting

entangled in the system's dangerous

rotating connections. The master shield

extends over the top and around the

sides of the spline and protects the

operator from the rotating spline and front

universal joint. People become entangled

in this area when boot laces or other

articles of clothing catch on the locking

pin, bolt, or grease fitting. The implement

shield is similar in appearance to the

master shield and offers protection from

the rear universal joint and implement

connection.

One or more of these shields are

frequently missing. Operators sometimes

remove shields because they make

hitching up equipment inconvenient or

impossible. They may remove damaged

shields and not replace them. Shields

may be missing when used tractors or

equipment are purchased.

PTO Accidents

Most PTO accidents and injuries occur

when a person's clothing or hair becomes

entangled with a part of the spinning PTO

system. Protruding components such as

the locking pin, bolt, cotter pin, grease

fitting, nails, universal joint, and tractor

spline readily hook and grab loose or

dangling clothes or hair. Boot laces, pant

legs, coat or shirt cuffs and tails,

drawstrings on windbreakers or hooded

sweatshirts, and scarves frequently get entangled. Cases have

also been reported of long hair getting

caught in PTOs.

Table 1: Lapsed Time vs. Distance Traveled

And how it relates to a tractor PTO turning at 540 and 1000 rpm-shaft/shield diameter of 3 inches

540 RPM |

1000 RPM |

|||

Lapsed time in seconds |

Revolutions Turned |

Distance Traveled (ft.) |

Revolutions Turned |

Distance Traveled (ft.) |

0.15 |

1.4 |

1.1 |

2.5 |

2.0 |

0.25 |

2.3 |

1.8 |

4.2 |

3.3 |

0.33 |

3.0 |

2.4 |

5.5 |

4.4 |

0.40 |

3.6 |

2.8 |

6.7 |

5.2 |

0.50 |

4.5 |

3.5 |

8.3 |

6.5 |

0.60 |

5.4 |

4.2 |

10.0 |

7.9 |

0.70 |

6.3 |

4.9 |

11.7 |

9.2 |

0.80 |

7.2 |

5.7 |

13.3 |

10.5 |

1.00 |

9.0 |

7.1 |

16.7 |

13.1 |

1.50 |

13.5 |

10.6 |

25.0 |

19.6 |

3.00 |

27.0 |

21.2 |

50.0 |

39.3 |

5.00 |

45.0 |

35.3 |

83.3 |

65.5 |

10.00 |

90.0 |

70.7 |

166.7 |

130.9 |

60.00 |

540.0 |

424.1 |

1000.0 |

785.4 |

Once clothing or hair is caught, the PTO's speed of rotation, combined with the power exerted by the tractor, makes escape unlikely and injury almost certain. Following are some typical outcomes:

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More