Transporting grain and silage from fields to farmsteads and from farmsteads to markets has changed over the years from strictly tractor and wagon units to a variety of large trucks and trailers. This change has occurred as farms have increased in size and become more geographically dispersed, and as farmers maximize harvesting and transportation efficiencies while holding down labor costs. Included among the types of large trucks and trailers found now on farms are semi-trailer end-dump trucks, pup trailers, truck and grain trailers, and regular and long-bed straight trucks. Hereafter, these units will be referred to as large farm dump trucks and trailers. All farm dump trucks and trailers use a hydraulic hoist to dump their loads. These same vehicles and trailers may also be used to transport and dump sand, gravel, firewood, debris or other similar materials. This fact sheet will examine large farm dump truck and trailer safety issues relating to the use of these units on farms.

What happens?

Three situations present the most potential for a fatal injury involving on-farm use of large farm dump trucks and trailers. One situation involves trucks and/ or trailers tipping over while emptying loads. This can happen for a variety of reasons and will be discussed in more detail later. A second situation is when a person works under a raised truck or trailer bed. Usually the person has not physically blocked the bed from coming down unexpectedly. The third scenario is when the truck or trailer bed comes into contact with overhead electrical lines and the driver or an on ground person is electrocuted. This usually happens when a driver pulls away after emptying the load without lowering the bed. In all three scenarios, a person can be crushed to death or electrocuted within seconds. There have been at least eight incidents in Pennsylvania involving farm dump trucks and trailers resulting in on-farm fatalities over the last twenty years. Five of these cases involved the victim being crushed between the bed and frame of the vehicle.

Figure 1: Raised beds of large farm dump trucks and trailers present several possible hazards.

Raised Dump Bed Hazards

Raising the bed of farm dump trucks and trailers may expose workers to potential hazardous conditions. All of these potentially hazardous conditions can be controlled or eliminated by applying known solutions before, during and after dumping loads. Identified below are several potential hazardous conditions relating to raised dump beds and how these conditions may be controlled or eliminated.

Instability. A dump truck or trailer becomes less stable as its bed is raised, particularly when the ground is less than perfectly flat. The greater the length of the truck or trailer bed, or the greater a slope, the greater is the hazard of tip over. As the bed is raised, it is important that the load center of gravity stay between the frame rails of the bed, preferably right in the center. Even when the ground is relatively flat, a slight slope can be created by one set of tires setting in a hole or deep set of ruts, low tire pressure on one side, or a ground depression that is created on one side as an off-center load is unloaded on soft ground. Often it is a combination of these conditions that result in instability and a tip over. Figure 2 shows the tip over hazard from raised beds on sloped ground. A longer bed presents a greater risk of tip over than a shorter bed.

Figure 2: Raising a bed on sloped ground increases the tip over hazard. A longer trailer increases this risk.

Wind, off-center loads and jack-knifed trailers add to instability hazards. Longer trailers provide more surface area for high winds to create lateral pressure on the trailer increasing the chance of a tip over. Jack-knifed rigs often leave the cab in a position to be crushed if the trailer does tip. This hazard is increased if the ground is uneven, there is high wind, and/or the load is not centered or shifts off-center while being unloaded. Off-center and shifting loads can occur for a variety of reasons including the load not distributed properly when it was loaded (e.g., top-heavy or too much on one side), material not flowing evenly out of the bed (e.g., wet or frozen material may stick to a side), or again, if the ground is uneven or tires are low on one side.

Unexpected Bed Lowering. Workers can be crushed to death almost instantly by dump beds that come down unexpectedly, either from an inadvertent lowering of the bed, failure of bed lift components (e.g., pins, bushings), or the collapse of the hoist cylinder. A worker most often places him or herself between a raised dump bed and truck or trailer frame to check on unexpected noises or possible malfunctions, and to perform routine maintenance (e.g., greasing) and repairs. A bed can be lowered inadvertently by a co-worker or by a worker inadvertently tripping a remote control lever. Bed lift components, such as hinge pins, bushings and structural arms, are most likely to fail when under pressure from a raised bed, especially if there is a load in the bed.

Hydraulic hoists may lower suddenly from the cylinder(s) losing pressure. This may happen when cylinder components (hoses, valves, rings) fail or leak from wear or too much pressure. Too much pressure can occur if an original lift cylinder system has been repaired or replaced with a smaller system, or if the truck or trailer bed is either significantly or constantly overloaded. Truck and trailer beds should be outfitted with a lift arm support that can mechanically block the bed from coming down. Figure 3 illustrates how to safely approach the underneath of a raised bed.

Figure 3: Always engage the lift arm support before placing yourself beneath a raised bed.

Contact with Overhead Wires. Overhead power lines are always a hazard on farms. Contact between overhead lines and grain augers or hay and grain elevators may be more familiar, but the same possibility of electrocution exists with raised truck and trailer beds. Contact between a raised dump bed and a power line is most likely to occur when the truck is pulled forward with the dump bed still raised. This may happen because of forgetfulness by the driver but is more likely to happen because of haste or impatience: the driver doesn’t want to wait for the bed to completely lower before pulling away.

In such cases, the driver is normally protected from electrocution because he or she is insulated from the electrical charge by the truck tires. Only if the driver leaves the cab and is simultaneously in contact with the ground and the truck will he or she be electrocuted. Unfortunately, some drivers, either from panic or lack of knowledge, attempt to leave the cab and become electrocuted. If a person, for example a helper, is on the ground touching any part of the truck or trailer when contact with an overhead power line is made, the person may be electrocuted instantly.

Additional Hazards

There are a number of additional hazards associated with using large farm dump trucks and trailers on farms that may or may not involve a dump bed in a raised position. For instance, slips and falls may occur when climbing on and off trailer beds. Crushed fingers and hands may result from opening and closing the latches of tailgates, or from tailgate hinges. Helpers may be crushed between a trailer dump bed and building or other structure, or even runover, while helping a driver back into a tight or close-quarters unloading location. Injuries from these types of incidents may range from minor, such as a pinched finger, to life threatening, such as being completely crushed between a backing trailer and building. Additionally, there is another hazard involving stability to be identified.

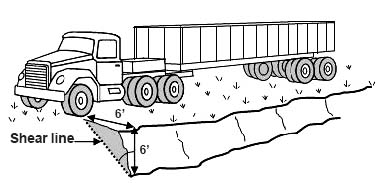

Collapsing Lane Shoulders and Ditch Banks. Large farm dump trucks and trailers can exert considerable pressure on the banks of ditches and shoulders of lanes that run along fields. For example, a 28 foot semi-trailer end-dump truck with a legal road travel Gross Vehicle Weight (GVW) of about 76,000 lbs. (38 tons) is much heavier than a large combine, which may be closer to 20-25 tons. If soil is weakened from freezing and thawing (heaving), or prolonged wet weather, and the truck is driven on the shoulder or too close to the ditch, the weight may be enough to collapse the soil, resulting in a tip over. This same hazard, usually referred to as the shear line hazard, exists when any large tractor or combine operates near a ditch bank. Figure 4 identifies the shear line of a six foot ditch bank.

Figure 4: The shear line distance is typically equal to the height of the drop off.

Controlling and Eliminating Hazards

There are many different ways to decrease the hazards associated with using large farm dump trucks and trailers. These include design features of the truck and trailer, actions associated with loading and unloading, maintenance of bed lift components and the bed itself, and driver training. These are listed below by each type of consideration.

Design Features

Publication #: E-44

The Pennsylvania State University is committed to the policy that all persons shall have equal access to programs, facilities, admission, and employment without regard to personal characteristics not related to ability, performance, or qualifications as determined by University policy or by state or federal authorities. It is the policy of the University to maintain an academic and work environment free of discrimination, including harassment. The Pennsylvania State University prohibits discrimination and harassment against any person because of age, ancestry, color, disability or handicap, national origin, race, religious creed, sex, sexual orientation, or veteran status. Discrimination or harassment against faculty, staff, or students will not be tolerated at The Pennsylvania State University. Direct all inquiries regarding the nondiscrimination policy to the Affirmative Action Director, The Pennsylvania State University, 328 Boucke Building, University Park, PA 16802-5901, Tel 814-865-4700/V, 814-863-1150/TTY.

PSU

First Edition 07/05

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More