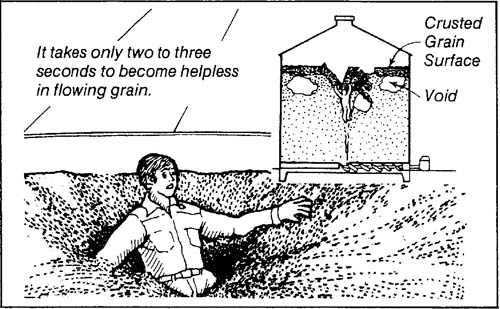

It takes only two or three seconds to become trapped in flowing grain. Within another 10 seconds, you can be completely submerged!

Innocent-looking grain storage bins have provided settings for hundreds of deaths and entrapments across North America. Victims are most commonly engulfed while walking across the grain surface during bin unloading. This is a simple way to avoid this tragedy — never enter a grain bin while the the unloading auger or suction tube is running.

How Grain Entrapment Incidents Happen

1. Engulfment in a Flowing Grain Column

Grain flows in a funnel-shaped path to the unloading auger. This vortex of grain behaves very much like a water whirlpool. Velocity increases as grain flows from the bin wall at the top of the grain mass into a small vertical column at the centre of the bin.

The vertical column flows down through the grain mass at close to the rate of the unloading auger. Essentially no grain flows in from the surrounding mass.

Rate of inflow at the centre top of a grain bin is so great that escape is impossible. Once engulfed in the grain flow, a victim is rapidly drawn down toward the bin floor.

The few survivors of this type of entrapment say they deliberately covered their mouths and noses with their hands and did not panic. All expressed amazement at the tremendous speed of their engulfment.

2. Entrapment in Grain Transport Vehicles

Many entrapments and suffocation have occurred in high capacity grain transport equipment. Victims are either buried during loading from combine or storage, or drawn into the flow of grain as a vehicle is being unloaded. Most victims of this type of accident are under 16 years of age — don’t allow youngsters to enter grain transport equipment.

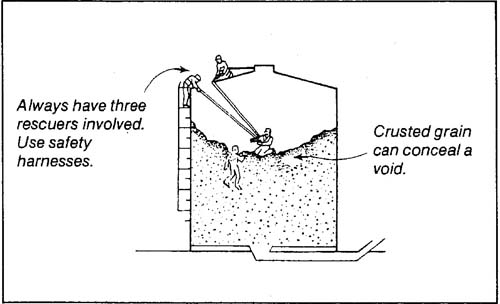

3. Collapse of Horizontal Crusted Grain Surfaces

A thin layer of crusted, spoiled grain can conceal voids beneath the surface. A victim who breaks through this crust is quickly covered as an avalanche of grain collapses into the cavity.

4. Collapse of Vertical Crusted Grain Surfaces

Spoiled or caked grain can stand almost vertically. As grain is removed from the base of a caked mass, the potential for avalanche and engulfment increases dramatically.

5. Suction Equipment Hazards

Recently, an Ontario transport driver was buried in an avalanche of grain as he attempted to empty a bin from the inside with conventional suction equipment. All bins should be equipped with properly designed doors o permit suction unloading from the exterior only.

Precautions for Rescuers

1. Always assume that an entrapped victim is alive.

2. Under no circumstances should you start an unloading auger or open a gravity flow gate. The victim could be drawn into the auger or become wedged in the opening.

3. If bin entry is required, the rescuer who goes into the structure should wear a body harness and be tied with a safety rope to at least two rescuers on the roof of the bin.

Rescue Situations

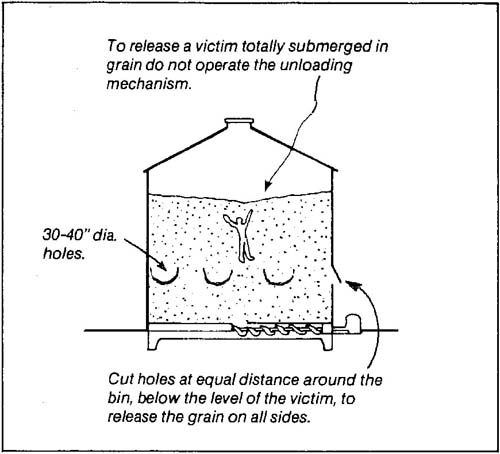

A. Victim Completely Submerged

1. First turn on bin aeration fans to provide as much air as possible to the victim. The extra air has been credited with saving several lives in grain bin rescues. Next, call the local rescue squad to get experienced help to the accident site.

2. Remove grain from the bin in the most rapidly and orderly manner possible. Attempts to ‘dig’ a buried victim free are generally fruitless, because of the massive amount of material involved and the tendency for grain to backflow.

Large openings should be cut uniformly around the base of the bin. Cut with an abrasive saw, air chisel, or cutting torch. These openings will greatly speed up grain removal. (If a torch is used, be alert for fire.) If suitable cutting equipment isn’t available, use the corner of a tractor bucket to ram holes in the bin wall.

3. Cut emergency openings four to six feet above ground to reduce the potential for a grain build-up around the outside of the bin — this would block the flow. Ideally, you should make semi-circular of V-shaped cuts 30 to 40 inches across to form valves, which when bent up, allow grain to flow freely. When bent back into place, they slow or stop the flow. This type of control protects rescue workers inside of the bin, who otherwise might be drawn in to a rapid, uncontrolled flow of grain.

4. Space openings uniformly around the bin to reduce the risk of structural collapse and to make it easier to remove grain from around the base. Once the victim has been uncovered, the bin openings can be closed to allow safe access by rescuers.

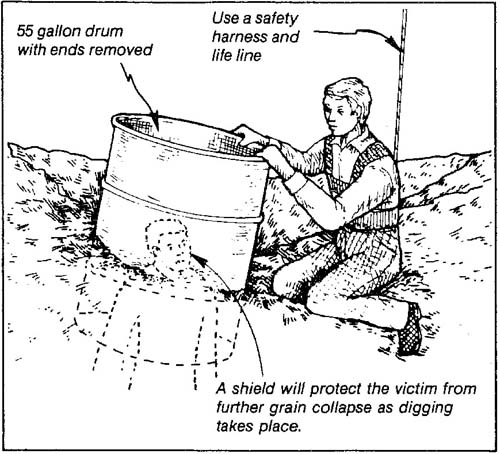

B. Partially Submerged Victim

1. If possible, lower a rescue squad member into the bin to reassure the victim and to attempt to attach a body harness or life line. Don’t try to pull the victim free with the line. The tremendous drag of the grain could cause further injuries. The life line is only intended to prevent further sinking.

2. Check the victim’s airway for grain. If he/she is experiencing breathing difficulties, administration of oxygen will help. Panic and struggle may be the chief reasons for respiratory problems, so try to calm the victim.

3. Construct a shield if there is further danger of grain collapse. A steel drum with both ends removed, plywood and pieces of sheet metal formed into a circle have all been used successfully.

You may need to remove a portion of the bin’s roof to get material inside. Once the shield is in place, it may be possible to free the victim by scooping grain from the inside of the shielded area. Use a board or sheet of plywood as a work platform.

You can avoid entrapment by making it a policy never walk on a stored grain surface. If entry is essential, use the life line and ‘buddy’ system!

Publication #: F-004

The information and recommendations contained in this publication are believed to be reliable and representative of contemporary expert opinion on the subject material. The Farm Safety Association Inc. does not guarantee absolute accuracy or sufficiency of subject material, nor can it accept responsibility for health and safety recommendations that may have been omitted due to particular and exceptional conditions and circumstances.

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More