Those big round bales weigh 1,000 to 2,000 pounds. Developing

safety awareness begins with the operator's manual. Take time

to read through it when the machine is new, and make sure each

operator reads or reacquaints himself with the manual at the

beginning of each season. Make sure that all employees are trained

and know how to operate the equipment.

- Before starting, inspect the tractor-baler combination.

Make sure all shields are in place, especially the Power

Takeoff (PTO) shields. Pull hard on the PTO shaft to ensure

it is properly locked on the splined shafts. Check the PTO

speed range to be certain 1,000-RPM isn't used where 540

may be specified.

- Check the maintenance records of the baler prior to starting

a new baling season. Excessive grease or grass buildup on

moving parts may cause a fire hazard that should be removed

periodically.

- A 5 lb. A: B: C fire extinguisher is recommended as part

of your tractor equipment.

- When working on this equipment, chock the baler wheels,

lock the tractor brakes, and remove the ignition key. Removing

the key may prevent a hasty helper from starting something

he shouldn't have.

- Thoroughly clean the baler to remove any accumulated

field trash or other debris.

- Lubricate all parts according to manufacturer's recommendations.

Proper lubrication can reduce unnecessary wear on parts

and prevent overheating that could cause a fire.

- Carefully check for loose or missing nuts, bolts, screws,

guards or bent teeth.

- Replace missing guards to prevent accidental contact

with the components they guard.

- Replace bent or missing pickup teeth to ensure effective

feeding of material into the feed rolls.

- Inspect all belts or chains for evidence of wear or breakage.

- Maintain belt tension according to the manufacturer's

recommendations.

- Belt lengths should be matched to prevent slippage that

can cause plugging and heat buildup.

- Belts that must be spliced should be trimmed and laced

squarely.

- New belts should be checked periodically until they are

broken in and length has stabilized.

- Before replacing a belt or chain, consult the operator's

manual for instructions on securing the upper chain or moving

load from the belt tension springs.

- Make sure the hydraulic hoses are clean and in good repair

and hooked up correctly.

- Check the twine feeding and cutting mechanisms to see

that they are working properly and that your twine is in

good condition.

- Also check the slip clutch, roll scraper and rear gate

latch to make sure they are adjusted and functioning according

to the manufacturer's recommendations.

- Finally, check all lights and warning reflectors, and

clean your slow-moving vehicle emblem. Check your fire extinguisher

to see that it is in proper operating condition.

The terrain and the density of the crop determine the windrower

speed.

- When operating over rough terrain or on hillsides, take

care to avoid holes or obstacles that can tip a windrower

or throw you from the machine. Crop density also affects

the speed at which you operate the windrower.

The more often you must unplug the machine, the higher the chances

for an accident.

- If clogs must be removed, always turn off the machine.

Repeated plugging of the baler may tempt the operator to try

unplugging the baler while it is running.

- Never try to unplug the baler until you have disengaged

the power takeoff and shut off the tractor engine.

- Also, never attempt to feed the material into the baler

by hand or feet. One slip could be deadly.

- Never attempt to hand feed or remove twine from the machine

while it is running.

You've completed your preliminary safety checks, and now you're

ready to make hay.

- Before transport to the field, make sure the two independent

brake pedals are joined together.

- Pump the brakes lightly to be certain the brakes are

working.

- Clean the SMV symbol.

- Make sure the baler and tractor tire pressures are correct.

Remember, when loaded, soft tires cause equipment to drift

on slopes.

Children should be kept away from the baling operation at all

times.

- Riders should never be allowed on the tractor or baler.

- Moving machinery is much faster than human reaction time,

so keep your body and clothing away.

- Do not hand feed any material into the baler, for your

natural tendency is to grasp harder as the machine pulls.

- Never leave the tractor seat with the engine running,

even if the PTO is disengaged. PTO's have been known to

self-engage due to vibration, or mechanical problems.

- When ejecting a bale, always make sure the area behind

the baler is clear before raising the tailgate and don't

eject on a downward slope as the bale may continue to roll.

- If the tailgate must be opened for maintenance or repair,

install a mechanical hydraulic cylinder lock out device

to prevent accidental gate closing.

The center of gravity is important in handling large round bales:

- The load should be kept as low as possible to prevent

backward or side overturn of the tractor.

- When traversing even slight embankments with a heavy

load, tractors can overturn, so brake gently when necessary.

- As you transport the bale down a steep grade, never push

in a tractor clutch pedal.

- Disengaging the clutch often causes the tractor to speed

ahead, then engaging the clutch or braking may cause a load

shift or overturn.

- When picking up a bale on a steep hillside, work on the

downhill side.

- Lifting round bales with a front-end loader is discouraged

unless proper bale restraining devices are used.

Movement of agricultural equipment on highways and roads requires

special care. Moving a number of large bales at one time can

cause braking problems.

- Always make sure that the load being pulled is no heavier

than the pulling unit. Also, use the same gear going down

a hill as you would go up a hill.

Keep in mind that most tractors have only two wheel brakes.

Five or six bales on a trailer may weigh 9,000 to 10,000 pounds.

- Make sure the load you are moving is not too wide.

- Finally, be sure that your slow moving vehicle emblem,

reflectors, and lights are in proper working order and meet

legislated requirements.

- For your own protection, check with the local police

force or Ministry of Transportation concerning the movement

of agricultural equipment and bale loads on public roads.

The flywheel maintains the uniform momentum of a baler's working

parts. It also keeps the machine operating for a considerable

time after power is disengaged.

-

Never attempt to work on a baler until the flywheel has completely

stopped.

-

The flywheel can be turned manually to permit slow motion

observation of knotter function. However, it should never be

turned while someone else is working on the knives, knotter

or other moving parts.

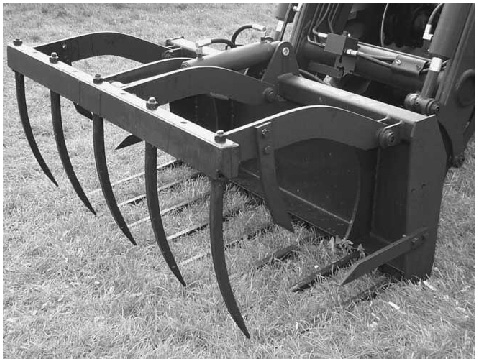

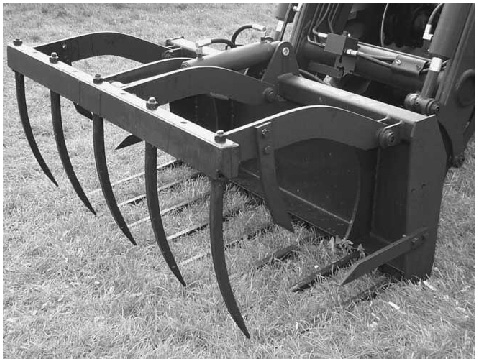

Big round bales can weigh over 1000 pounds. There are some key

points to consider when harvesting and handling large round

bales.

- Equipment used to handle the big bales should be fitted

with rollover protective structures.

- Never attempt to carry a round bale in a loader bucket.

- All loaders should be equipped with a spear or grapple

that is specifically designed for the size of the round

bales being handled.

- Loaders should be equipped with a restraining device

that will prevent a loose bale from sliding backwards.

- Loaders must be large enough and equipped with sufficient

counterweight to handle bales safely.

- Set wheels at maximum width to increase stability.

- Avoid steep slopes and rough terrain when moving bales

with a loader. If it is impossible to avoid sloping land,

approach bales from the downhill side.

- Avoid sudden stops, starts or changes of direction. Be

very cautious and travel at low speed when carrying a bale.

- Always keep bales as low as possible for maximum stability.

The risk of a bale breaking free is greater when loader

arms are raised because the load is less stable.

- Wagons used to haul bales should be of sufficient width

and have end racks to prevent bales from moving off the

ends and sides during transport. There are wagons designed

specifically for transporting round bales.

- Use good judgment when stacking bales in storage. High

stacks make efficient use of available space, but removing

the bales could be hazardous.

- Carefully transport round bales from the field to storage.

- Do not travel too fast and make sure that there is adequate

ballast on the front and rear to counter balance the load.

-

Always disengage the PTO and shut off the tractor before working

on equipment.

The flywheel supplies a uniform momentum for operating parts

and will continue to turn even after the PTO is disengaged.

-

Always allow time for it to stop turning before working on

the baler.

Knotter operation can usually be viewed by a hand turning the

flywheel.

- Be watchful for coworkers when two or more are working

on/adjusting equipment.

-

Extra caution is needed when bale throwers are used because

of potential energy in the unit.

As always, caution is needed when loading small bales by hand

onto wagons. The experience of the stacker and the person driving

the tractor or truck pulling the wagon are important elements

for safely loading and hauling wagons from the field. The newer

large square balers pose an even greater risk because of the

larger tractors needed for operation and the weight of the bales

produced.

The

information and recommendations contained in this publication

are believed to be reliable and representative of contemporary

expert opinion on the subject material. The Farm Safety Association

Inc. does not guarantee absolute accuracy or sufficiency of

subject material, nor can it accept responsibility for health

and safety recommendations that may have been omitted due to

particular and exceptional conditions and circumstances.

Copyright © 2002 Farm Safety Association Inc.

22-340 Woodlawn Road West, Guelph, Ontario (519) 823-5600.

Disclaimer and Reproduction Information: Information in

NASD does not represent NIOSH policy. Information included in

NASD appears by permission of the author and/or copyright holder.

More