The Power Take Off (PTO) shaft is an efficient means of transferring

mechanical power between farm tractors and implements. It is

also one of the oldest and most persistent hazards associated

with farm machinery.

Typical injuries resulting from getting caught in an open power

takeoff shaft are amputations, severe lacerations, multiple

fractures, spine and neck injuries or complete body destruction.

Broken arms, broken legs and severe facial lacerations are common.

Spine and neck injuries are common if a person is rotated around

the shaft.

All it may take for a person to become entangled in an open

power takeoff shaft is one single thread, string from a hooded

parka or strand of loose hair. As the items begin to wrap extremely

fast around the power takeoff shaft they pull the victim directly

into the PTO unit.

The following parts of the PTO have been found to be hazardous:

Power Take-Off (PTO) Stub: Most incidents involving

PTO stubs stem from clothing caught by an engaged but unguarded

PTO stub.

The reasons a PTO stub may be left engaged include:

The operator forgetting or otherwise not being aware the PTO

clutch is engaged. Seeing the PTO stub spinning but not considering

it dangerous enough to disengage, or, where the operator is

involved in a work activity requiring PTO operation.

Boot laces, pant legs, coveralls, sweat shirts, and windbreakers

are clothing items that can become caught and wrapped around

a spinning PTO stub shaft.

The PTO driveline hazard - This drive shaft is

known as the implement input driveline (IID). The entire IID

shaft is a wrapping point hazard if it is completely unshielded.

If the IID shaft is partly guarded, the shielding is usually

over the straight part of the shaft, leaving the universal joints,

the PTO connection (the front connector), and the Implement

Input Connection (IIC, the rear connector) as the wrapping point

hazards.

The machine IID shaft is coupled to the tractor

PTO stub. At recommended or slower speeds clothing is pulled

around the IID shaft much quicker than a person can pull back

or take evasive action. Once wrapping begins, the person instinctively

tries to pull away. This action simply results in a tighter,

more binding wrap.

If an IID shaft is coupled to the tractor PTO stub but no other

hitch is made between the tractor and the machine, then the

tractor may pull the IID shaft apart. If the PTO is engaged,

the shaft on the tractor end will swing wildly and may strike

anyone in range. The swinging force may break a locking pin

allowing the shaft to become a flying missile, or it may strike

and break something that is attached or mounted on the rear

of the tractor.

Separation of the driveline shaft is not a commonly occurring

event. It is most likely to happen when three-point hitched

equipment is improperly mounted or aligned, or when the hitch

between the tractor and the attached machine breaks or accidentally

uncouples.

Protruding pins and bolts used as connection locking

devices are particularly adept at snagging clothing. If clothing

doesn't tear or rip away, as it sometimes does for the fortunate,

a person's limb or body may begin to wrap with the clothing.

Even when wrapping doesn't occur, the affected part may become

compressed so tightly by the clothing and shaft that the person

is trapped against the shaft.

Other unsafe practices include mounting, dismounting,

reaching for control levers from the rear of the tractor, and

stepping across the shaft instead of walking around the machinery.

An extra rider while PTO powered machinery is operating is another

exposure situation.

SHIELDING THE TRACTOR

Master Shield:

The first shield in the PTO driveline is the master shield on

the rear of the tractor. This shield prevents the operator from

accidentally coming into contact with the tractor stub shaft

and the front universal joint of the equipment's driveline.

Operators should make it a practice to replace the tractor PTO

shaft guard, which completely covers the tractor stub shaft,

when the PTO is not in use.

SHIELDING PTO-OPERATED

EQUIPMENT

Fully

Shielded Driveline:

This type of driveline shielding encases the shaft in a plastic

or metal casing supported by bearings at each end of the shaft.

The bearings allow the shield to stop spinning if someone or

something comes into contact with the driveline, while the shaft

inside continues to spin.

The ends of the driveline shield are bell-shaped to cover the

universal joints of the shaft. Because universal joints are

irregularly shaped and prone to grab objects, operators should

never modify the bell-shaped shield to make maintenance, greasing

parts or connecting the shaft easier.

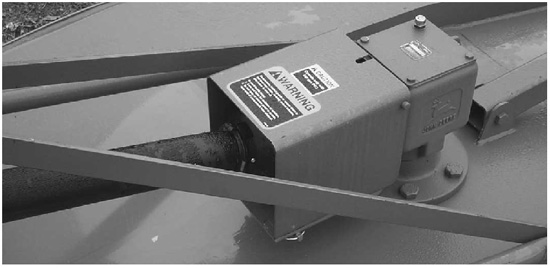

Guards: Manufacturer installed guards must be

replaced when removed for maintenance. These guards are designed

to protect the operator and equipment. Guards not only reduce

the risk of an injury; they also keep dust and other foreign

objects from damaging gears and other moving parts.

MAINTENANCE

Like any

moving part, the driveline shield must be maintained to ensure

proper operation.

PTO equipment is frequently operated in inclement weather and

exposed to dust, chaff and other foreign materials, which can

quickly damage the bearings that allow the shaft to spin freely

inside the shield.

Rust, dirt and crop debris must be cleaned frequently to allow

the bearings to spin freely. Replace any damaged or worn shields

with the manufacturer's recommended parts. Storing equipment

inside will also help extend the lifetime of the equipment and

reduce maintenance costs. Many newer machines have a bracket

attached to keep the driveline off the ground, thus preventing

dirt and other materials from damaging it.

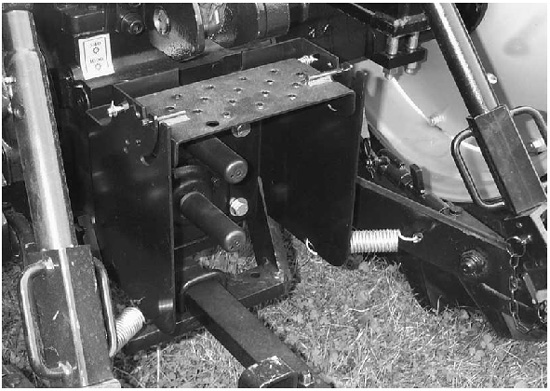

POSITIONING THE DRAWBAR TO THE PTO SHAFT

The length and height of a tractor drawbar may need to be adjusted

to match the implement to the manufacturer's specifications.

It is important to make these adjustments to ensure that the

PTO driveline does not compress or separate during operation.

To make this adjustment, check the implement manufacturer's

recommendations and adjust the height of the drawbar and the

distance from the PTO stub shaft to the center of the drawbar

hitch hole (see Figure 2).

Failure to match the drawbar to the implement can result in

the driveline being compressed or separated when the tractor

makes a sharp turn or comes to the top or bottom of a hill.

Separation or compression frequently damages the protective

shield to the point where it no longer slides together or allows

the shaft to spin freely inside the shield.

Most PTO-driven equipment has some form of a shear pin to prevent

damage to the shaft or gearbox. Always follow the manufacturer's

recommendations for size and hardness when replacing a damaged

shear pin or bolt. Using a pin or bolt that is longer than necessary

creates a potential catch point that may snag the operator's

boot lace or clothing, resulting in a possible entanglement.

PTO SAFETY PRACTICES

Always

disengage the PTO, shut off the engine and remove the key before

getting off the tractor.

This protects you from accidental entanglement while servicing

the equipment and ensures that no one else can start the tractor

during maintenance procedures.

Keep the master shield in place at all times.

The master shield should be removed only when required for hooking

up special equipment with equivalent shielding. Replace the

PTO tractor stub shaft guard whenever PTO driven equipment is

not being used.

Check that the PTO driveline shields are in good condition.

With the PTO stopped, test driveline guards by spinning or rotating

them to ensure they have not become stuck to the shaft the shield

should rotate freely by hand. Make any necessary repairs to

damaged bearings or shields.

Never modify driveline shields to make servicing or connections

easier. Cutting or drilling a hole in the shield allows

dirt; chaff or other foreign materials access to shaft bearings.

This reduces the life of the shield and also increases the risk

of the operator getting clothing caught in the spinning shaft.

Always use the driveline recommended for your machine. Never

switch drivelines among different machines.

Never step across a rotating PTO driveline. Always

take the time to walk around a rotating shaft. Although the

shaft may be enclosed in safety shields and guards, there is

a chance that clothing could be caught in the spinning shafts.

Reduce PTO shaft abuse by observing the following: avoid

tight turns that pinch rotating shafts between the tractor and

machine; keep excessive telescoping to a minimum; engage power

to the shaft gradually; and avoid over tightening of slip clutches

on PTO-driven machines.

Wear snug fitting clothing. Bulky, loose fitting

clothing can quickly be caught in a spinning shaft, entangling

an unsuspecting operator. Boots or shoes without laces are preferred

because laces may become entangled in the shaft.

STEPS TO FREE A

PTO ACCIDENT VICTIM

Rescue procedures

to remove a victim from the power takeoff shaft should start

by shutting off the tractor and making sure it will not restart.

Next, chock the tractor wheels so that the tractor cannot move.

The critical time to remove a victim from the equipment may

vary from only a few minutes to several hours.

There are several methods that can be used to remove a victim

from a PTO shaft:

The information and recommendations contained in this publication

are believed to be reliable and representative of contemporary

expert opinion on the subject material. The Farm Safety Association

Inc. does not guarantee absolute accuracy or sufficiency of

subject material, nor can it accept responsibility for health

and safety recommendations that may have been omitted due to

particular and exceptional conditions and circumstances.

Copyright © 2002 Farm Safety Association Inc.

22-340 Woodlawn Road West, Guelph, Ontario (519) 823-5600.

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More