Foaming pit coming through floor slats

(from University of Minnesota,

http://www.extension.umn.edu)

Read this before disturbing foaming manure pits.

In the Midwest, an estimated 24% of swine barn manure pits have experienced “foaming”. This foam traps a high concentration of methane gas (50 – 70%) that is rapidly released into the environment when the foam is disturbed, resulting in a hazardous environment. These high concentrations can cause flash fires or explosions if there is an ignition source in the room. Since 2009, at least 11 explosions have occurred in upper Midwest barns from methane releases in foaming manure. These explosions have destroyed barns and injured workers.

Do not disturb the foam without taking precautions.

Methane and hydrogen sulfide gases are generated naturally in all anaerobic manure pits. When foaming occurs, these gases become trapped in the foam’s bubbles, which may be comprised of 50 to 70% methane. The foam can be broken when agitating the manure, pressure‐washing, or dropping feed through the floor slats. When this happens, these gases are rapidly released into the air, resulting in potential explosive concentrations of methane. Hydrogen sulfide is released from the foam and is hazardous to breathe above 10 ppm. Methane gases are explosive when concentrations are between 50,000 to 150,000 parts per million (ppm). Within the foam, the methane concentrations are above the explosive limit, meaning there is not sufficient oxygen to be flammable. However, when the foam is broken and the gas is released, the gas dilutes in the air and quickly becomes explosive.

High concentration of methane gas is flammable: if there is any ignition source in the room when high concentrations of methane are released, an explosion could occur. Many Midwestern barns, both empty barns and barns with workers and hogs inside, have exploded when the surface of the foam has been disturbed. Sources sufficient to ignite methane include: cigarettes, electric motors (such as those for pressure washers and feed system), pilot lights, welding, metal cutting, or faulty or damaged wiring that can produce sparks. It is critical to eliminate all sources of heat or sparks before conducting tasks inside a barn with foaming manure when these activities can break the foam.

Many producers want to spray the foam with water will break it up: this is dangerous because it will release the methane into the room, increasing the risk of explosion. Before doing any activities that will disturb the foam, including wetting down the foam, washing the barn, or pumping a manure pit, follow the Steps in the inset box to prepare for high methane release from the foam. It is extremely important to shut off all possible ignition sources prior to doing any activity that will quickly break down the foam.

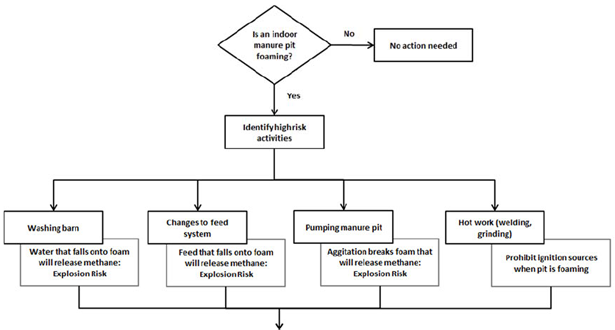

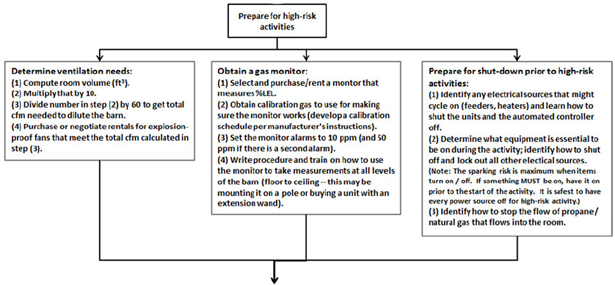

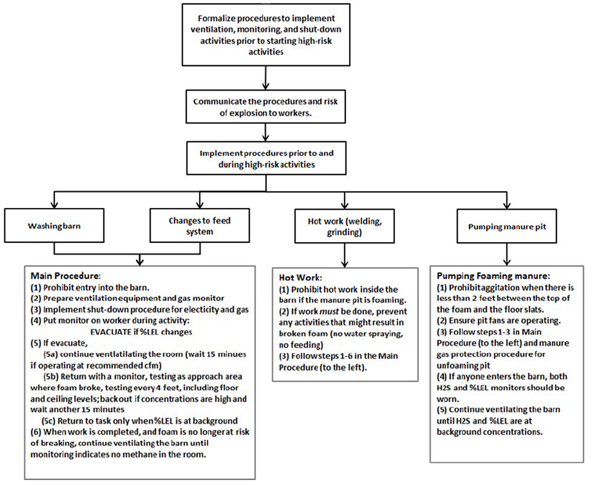

STEPS TO TAKE PRIOR TO DISTURBING FOAM:

Pressure washing inside the barn will usually resuilt in water entering the manure pit through the floor slats. This water is sufficient to break the foam, which can release dangerous methane concentrations. Follow procedures to eliminate ignition sources prior to pressure washing. It is safest to pressure wash with a very low volume of manure in the pit, when foam is minimal and pit fans are capable of venting manure pit gases.

Direct reading monitors, specific for combustible gases, are available to measure whether methane gases are released in the air. These devices can be expensive ($600-1200 each), and units require calibration to ensure accurate readings. You should select a meter that is "intrinsically safe" so that it does not introduce a spark that might ignite the methane in the room. Rental companies can provide calibrate monitors, but plan ahead to make sure you have monitors when you plan on activities that may release methane. These meters provide readouts that will indicate the presence of methane to let you know if the indoor environment has a problem. Evacuate the building if you see %LEL increase when wearing/using these monitors.

USING GAS MONITORS - LEL

Obtain a combustion meter or LEL monitor to measure methane concentrations in the air. Methane, once released, disperses throughout a building, and, since it is lighter than air, it may accumulate near the ceiling or in the attic if ther is little air movement. You should measure first in the area where foam is disturbed, and then measure throughout the barn, including near the ceiling, before restoring electricity to the barn. Use the combustion meter to measure explosive risk, continuously before, during and after the activity that might break the foam.

To minimize risk to the worker when monitoring, mounting the monitor on a pole or using monitors with extension wands and internal pumps can allow the user to be at a safer distance from pockets of methane. These also allow easier measurement near the ceiling, where methane can pool near electrical sources.

Inexpensive monitors can detect gases

and indicate dangerous concentrations.

The reading on most combustion meters indicate the gas concentration relative to its ability to combust or explode. Meters indicate the gas concentration in percent of the lower explosive limit (%LEL). Normal air should read 0% LEL. When the meter indicates 10% LEL, the air in the room has a significant concentration of combustible gas. This concentration can rise quickly with broken foam. Near the release, concentrations will quickly reach 100% LEL, where the gas can be ignited by any spark, resulting in an explosion. We recommend setting alarms to sound when the concentration reaches 10% LEL to quickly alert workers of a hazardous methane concentration. (Note: For methane, 100% LEL is 50,000 ppm. Hence, an alarm at 10% LEL would indicate methane concentrations of 5000 ppm, which indicates a risk of asphyxiation is starting to be a concern.)

Leave the area once the combustion meter reaches 10% LEL. Continue to ventilate the room when you are outside of it. Return, only with the combustion meter, checking to ensure that concentrations are again safe. Note that the meter only reads the concentration in the immediate vicinity of the monitor: if there is little air movement in the room, you may have pockets of concentration that are above safe levels. Hence, it is critical to have turned off electrical sources for the entire room and to check areas above you for methane if there is little air motion.

To increase ventilation, us an explosion

-proof fan with duct

Ventilating the barn to bring in fresh air is needed whenever actions might result in breaking the foam layer of a manure pit. Running the manure pit fans is not sufficient to remove methane from a room, particularly if the foam layer is deep and prevents air from being drawn across the manure pit. The room should be ventilated at a rate of 10 air exchanges per hour, which may be more than the typical ventilation capacity of a barn. Compute the total needed flow rate, in cfm, using the following: (1) determine the room volume (length x width x height, in feet), (2) multiply that by 10 and (3) divide that by 60 to get the total cubic feet per minute (cfm) flow rate needed for the room. Wall fans may not be sufficient to provide this level of air exchange, so portable fans might be needed. Use an intrinsically safe (or “explosion proof”) fan (that will not spark), and set it up to push fresh air into the room.

Currently, the answer is we don't know. Some barns may have one foaming pit in it while th other pit is not foaming. Researchers are examining sources, including microbial imbalance in these manure pits as a function of feed, water, and climate. While methane is always generated from anaerobic breakdown of manure in a pit, the foam traps the methane, preventing it from being exhausted by the pit fans. The foam traps methane over time, releaseing large amounts of methane in a short period of time when the foam breaks. Feed with higher dietary fiber have been implicated in foam stabilization. See references for current research updates.

Research is underway. Applying 5 pounds of Rumensin-90 per 100,000 gallons of pit volume, dosed over 6 weeks, has moderately reduced foaming, but is not always successful (MN, 2012). Continue to follow updates from your state Ag Extension or the National Pork Council for updates foam prevention and guidance on application of foam suppressants.

General Information on Foaming Manure Pits

Iowa Pork Producers Association publication for Understanding Foam & Pump-out safety:

http://www.farmerscoopsociety.com/userfiles/ file/Understanding%20Foam%20and%20Pump-out%20Safety.pdf

Iowa State University Extension and Outreach - Manure Management Action Group:

http://www.agronext.iastate.edu/immag/manurevideos.html

University of Minnesota Extension Office information on foaming manure:

http://www.extension.umn.edu/agriculture/manure-management -and-air-quality/feedlots-and-manure-storage/foaming-manure/

Pit Pumping safety - http://vimeo.com/15463270

Potential Causes of Manure Pit Foaming in Pig Finishing Barns

http://elibrary.asabe.org/azdez.asp?JID=5&AID=43495&CID=miss2013&T=2

University of Minnesota Extension Fact Sheet (Sept 5, 2012), Monensin addition to swine manure deep pits for foaming control- http://pigconnect.uwex.edu/files/2013/01/Adding-rumensin-to-swine-deep-pit-foaming.pdf

Gas-Vapor Monitoring References

NIOSH Technical Report: Components for Evaluating Direct-Reading Monitors for GAses and Vapors

http://www.agronext.iastate.edu/immag/manurevideos.html

OSHA Safety and Health Information Bulletin (SHIB 09-30-2013): Calibrating and Testing Direct-Reading Portable Gas Monitors https://www.osha.gov/dts/shib/shib093013.html

PennState Extension - Confined Space Manure Gas Monitoring FAct Sheet: http://extension.psu.edu/business/ag-safety/confined-spaces/manure/manure-pit-safety-fact-sheets/e-52

PROCESS to

PREPARE and PERFORM

HIGH-RISK ACTIVITIES with a

FOAMING MANURE PIT

Iowa FACE/GPCAH Hazard Alert

The University of Iowa Department of Occupational and Environmental Health

UI Research Park 240 IREH Iowa City, IA52242-5000

Toll free: 800.513.0998

http://www.public-health.uiowa.edu/FACE

E-mail: stephanie-leonard@uiowa.edu

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More