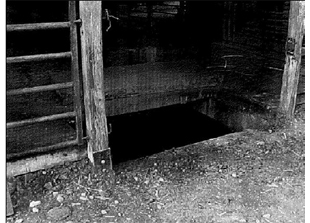

Access to manure pit where two died

after entering a manure pit, Iowa

FACE

2005 IA 024, 025.

Agriculture Workers Should Take Precautions Prior to Entering Manure Pits

People entering manure pits without taking proper precautions are at risk of dying from high exposures to hydrogen sulfide gas. Guidance on manure pit operations from ASABE specify the need to monitor these spaces prior to entry. This alert provides general guidance on risks of entering manure storage pits.

Do not enter manure storage areas without ventilating and measuring gas concentrations.

Four Midwestern farmers died in July 2015 from gas exposures when entering manure pits:

People cannot smell hazardous concentrations of hydrogen sulfide (H2S) and methane (CH4), but concentrations may be high enough to decrease oxygen or paralyze breathing. Concentrations change over time, and understanding how much gas is in the manure storage pit before each entry is important to prevent death. Monitors for measuring gas concentrations are available and should be used prior to entry into any manure storage area.

It is important to pre-plan for entering these pits. Developing, training, and following a confined-space program is important to make sure that no one enters a manure storage pit without taking proper precautions. Critical steps to follow in this plan include:

See “Identifying Hazardous Gases” detailed alert for specific information on selection and use of direct reading gas monitors and health hazards of these gases.

The table below provides guidance on hazardous concentrations of manure gases. The “High Alarm” typically results in louder alarm than the low, or first, alarm. If you don’t have two alarm set points, choose the low alarm setting in the table. IDLH is the concentration that is “immediately dangerous to life and health,” which is established by NIOSH (the National Institute of Occupational Safety and Health). The IDLH values identify concentrations that are ACUTELY hazardous (Danger!). If the monitor displays concentrations that are at or above the IDLH, immediately leave the area. The actions indicated are for the acute hazards to the person conducting monitoring. To safely work in the area, concentrations need to be below the alarm set points, as indicated.

| Set Alarm Levels* | ||||

|---|---|---|---|---|

| Contaminant | Low Alarm | High Alarm | IDLH | Notes |

| Oxygen, % (at sea level) | 19.5 | 19 | No IDLH: Leave if reach 19.5% | LEL may not read correctly if <19.5%, This presumes no O2 generation sources. |

| LEL,%** | 5 | 10 | Asphyxiant; watch Oxygen% changes | Remove all workers, animals from room if pit 50% LEL as methane (25,000 ppm)** |

| CO, ppm | 25 | 50 | 1000 | Headache at 100-400 ppm. If develop flu-like symptoms quickly; get out. |

| H2S, ppm | 25 | 35 | 300 | Eye irritation may prevent safe action above 140 ppm; lung irritation @ 100 ppm. |

| NH3, ppm* | 5000 | - | 40,000 (4%) will displace oxygen | Remove all workers, animals from room if pit gas> 32,000 ppm. ** |

| *Note: If you don't calibrate the LEL sensor with methane, you need to know the response to the calibration gas and how it related to methane. For example, calibration with pentane typically gives you %LEL readings higher than the true LEL. Check the operation manual for the sensor and monitor you have. | ||||

| *If CO2 and %LEL reach significant levels, it will displace oxygen. Watch changes in Oxygen % as an indicator of significant concentrations of these two contaminants combined. | ||||

| ** See ASABE S607 Table 7. | ||||

An additional, detailed fact sheet (“Technical Guidance for Selection and Use of Monitors”) provides specific information on selection, use, and general operation of these gas monitors. This is available on the “For Farmer” fact sheets on the GPCAH web site, at http://www.public-health.uiowa.edu/gpcah/fact-sheets/.

The faculty and staff of the Great Plains Center for Agricultural Health are able to help you with monitoring questions. Contact CPH-GreatPlainsCenter@uiowa.edu for assistance. We are glad to provide hands-on training and education to groups of interested farmers, emergency responders, and agricultural outreach organizers to develop expertise to protect farmers and those working on the farm.

General Information on Manure Pit Hazards

NIOSH has been providing information to prevent asphyxiation in manure pits since 1990.

See http://www.cdc.gov/niosh/docs/90-103/

The ASABE is a professional and technical organization dedicated to the advancement of engineering applicable to agricultural, food and biological systems. This organization has developed standards to recommend ventilation (S607) and operation (EP470.1) of manure storage pits with safety in mind. Their recommendations include monitoring spaces prior to entry.

ASAE EP470.1: https://elibrary.asabe.org/azdez.asp?JID=2&AID=39802&CID=s2000&T=2

ANSI/ASABE S607: https://elibrary.asabe.org/azdez.asp?JID=2&AID=36208&CID=s2000&T=2

General Confined Space Program Information

Michigan’s Department of Licensing and Regulatory Affairs has provided a sample written program for permit-required confined space entry that can be customized for farming operations: http://www.michigan.gov/documents/dleg/deleg_wsh_cet5330_346240_7.doc.

OSHA has developed training program to outline the confined space program (although this is for another sector, the images aren’t useful for agriculture, but the content is useful): https://www.osha.gov/Publications/2254.html

OSHA also provides assistance materials on confined spaces to all at: https://www.osha.gov/confinedspaces/index.html

Gas-Vapor Monitoring References

NIOSH Technical Report: Components for Evaluating Direct-Reading Monitors for Gases and Vapors http://www.agronext.iastate.edu/immag/manurevideos.html

OSHA Safety and Health Information Bulletin (SHIB 09-30-2013): Calibrating and Testing Direct-Reading Portable Gas Monitors https://www.osha.gov/dts/shib/shib093013.html

PennState Extension – Confined Space Manure Gas Monitoring Fact Sheet:

http://extension.psu.edu/business/ag-safety/confined- spaces/manure/manure-pit-safety-fact-sheets/e-52

FACE Reports

These comprehensive investigations provide details of what happened that caused or contributed to worker fatalities associated with manure storage pit entry. As important as the sequence of events are, these contain recommendations to prevent these from happening in your operation.

Iowa farmer and employee died after collapse and attempted rescue in manure storage pit (http://www.public-health.uiowa.edu/face/Reports/PDF-Reports/2005IA024-025.pdf)

Iowa hog farmer dies from asphyxiation after manure pit agitation

(http://www.public-health.uiowa.edu/face/Reports/ PDF-Reports/Manure%20Pit%20Agitation.pdf)

Minnesota farm owner and son asphyxiated in manure waste pit

(http://www.cdc.gov/niosh/face/In-house/full9229.html)

Minnesota hog farm co-owner and employee die of hydrogen sulfide poisoning in manure pit

(http://www.cdc.gov/niosh/face/In-house/full9228.html)

Five family members in Michigan die after entering manure waste pit on dairy farm (http://www.cdc.gov/niosh/face/In-house/full8946.html)

Equipment Rental Companies

Google search “Gas monitor rental” to identify monitor rental services. Ensure that the company will provide calibrated equipment, written certification of calibration in the shipment, and operation manual. Request they set the alarms to the limits you need prior to shipping.

Iowa FACE/GPCAH Hazard Alert:

General Dangers of Manure Storage Pit Entry

The University of Iowa Department of Occupational and Environmental Health

UI Research Park 240 IREH Iowa City, IA52242-5000

Toll free: 800.513.0998

http://www.public-health.uiowa.edu/FACE

E-mail: stephanie-leonard@uiowa.edu

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More