On September 30, 2013, a foreman at an auto salvage yard was severely injured when a loader tire’s sidewall failed, releasing an explosive blast of air which knocked him backward about 10 feet. He was hospitalized with injuries to his face and torso which included four fractured ribs. The tire was purchased used. It is unknown whether it had been previously damaged in such a way which would cause it to explode during inflation.

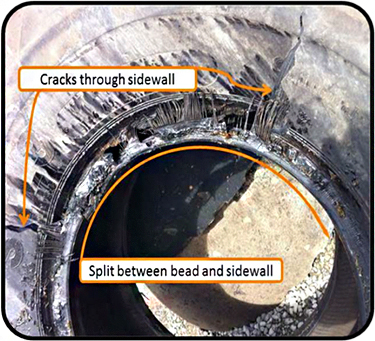

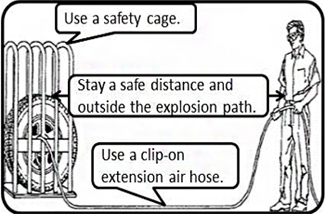

He was inflating the tire to seat it on its rim when the sidewall failed. The recommended maximum pressure to seat the bead of the tire was 40 psi; the compressor was set to fill the tire to 80 psi. To seat the bead, first inflate to 20 psi and inspect the tire for bulges or cracks. Never inflate tires over 40 psi when seating the bead. If both beads are not completely seated at 40 psi, deflate the tire and start over. Only after both beads are fully seated, inflate tires to recommended operating pressure.

When servicing split rim (multi-piece) wheels and single rim wheels used on large vehicles and off-road machines follow the requirements of WAC 296-864.

*Developed by Washington State Fatality Assessment and Control Evaluation (FACE) and the Division of Occupational Safety and Health (DOSH), WA State Dept. of Labor & Industries. The FACE Program is supported in part by a grant from the National Institute for Occupational Safety and Health (NIOSH grant# 5 U60 OH008487-09). For more information, contact the Safety and Health Assessment and Research for Prevention (SHARP) Program, 1-888-667-4277.

SHARP Report No.: 47-22-2013

Release Date: December 2013

Publication #: 47-22-2013| December 2013

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More