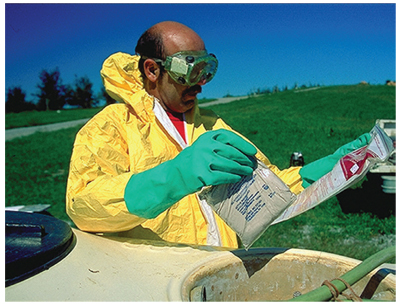

THE LABEL IS THE LAW! When using pesticide products, the

requirements for PPE on the product label are your main source of information.

The Environmental Protection Agency (EPA) has labeling requirements for pesticide products. Pesticide labels must have signal words, which describe the acute (short-term) toxicity of the formulated pesticide product. The signal word can be one of the following: DANGER/POISON, DANGER, WARNING, or CAUTION. Products with the DANGER/POISON signal words are the most toxic. Products with the signal word CAUTION are comparatively less toxic. All products must be handled with care. Manufacturers must provide information about what PPE a handler must wear when mixing, loading, handling, and applying pesticides. Some of this information may be confusing. For instance, what does the label mean when it specifies “chemical-resistant” protective clothing?

Polyvinyl chloride (reusable)

– prevent the measurable movement of certain chemicals through the material to your protected skin for a limited period of use or time. No material claims to be chemical proof. If the label refers to a chemical-resistance category (A – H), choose the category of resistance level that best matches the length of time you will be handling the pesticide or change (into a new pair of gloves, for instance) before you reach the resistance time limit for the material. (See the chart below). The resistance categories are based on the solvents used in the pesticides, not the active ingredients. Different formulations of the same pesticide may require PPE from different chemical-resistance categories.

– A one- or two-piece suit that the manufacturer specifies to be resistant to certain chemicals. Suits made of butyl rubber, neoprene, PVC, or one of the newer coated and laminated polyethylene fabrics may be appropriate. Generally, greater material thickness, bound or sealed seams, and covered zippers and vent holes will increase the protection offered. These garments are often elasticized at the wrist and ankle. Some are reusable if properly cleaned, and some must be disposed of after a single use. You will be safest and most comfortable in protective clothing that fits. Do not use coveralls made from fabrics such as cotton, polyester, or uncoated, non-woven olefin unless the label specifies “long-sleeved shirt and long pants” or “coverall worn over long-sleeved shirt and long pants.”

| Characteristics of some commonly-used pesticide coveralls (Consult manufacturers for more informaiton) | ||||||

|---|---|---|---|---|---|---|

| Material | Particulate Protection Class* |

Splash Protection Class* |

Liquid proof? |

Liquid chemical protection? |

Breathable? | Relative cost |

| Tempro® | IV | (none) | NO | NO | YES | LOW |

| ProShield2® | I | III | NO | YES | YES | LOW |

| Tyvek® | I | III | NO | NO | YES | LOW |

| Tyvek® QC / sewn seams | I | II | NO | YES | NO | LOW |

| Tyvek® QC / sealed seams | I | II | YES | YES | NO | Moderate |

| Kleenguard® LP | I | III | NO | NO | YES | LOW |

| Tychem® SL /surged seams | I | I | NO | YES | NO | Moderate |

| Tychem® SL /sealed seams | I | I | YES | YES | NO | High |

| PVC coverall | I | I | YES | YES | NO | High |

| PVC suit | I | I | YES | YES | NO | Moderate |

| *Protection Class is determined by the “Signal Word” on the pesticide label: | ||||||

| Class I = Signal words “DANGER” or “DANGER/ POISON” (highly toxic) | Class III = Signal word “CAUTION” (less toxic) | |||||

| Class II = Signal word “WARNING” (toxic) | Class IV = Signal word “CAUTION” (least toxic) | |||||

| NOTE: The equipment depicted in images and any brand names mentioned in this document are for illustrative purposes and should not be construed as an endorsement for a particular product. | ||||||

— Often, the pesticide label will provide recommendations for a type of glove in the PPE section. In addition, if the label specifies chemical-resistance categories A through H, use the table below to help you decide what type to provide.

(Note the reference to a standard glove thickness of at least 14 mils.)

Environmental Protection Agency chemical resistance categories for selected personal protective materials

| Type of personal protective material | ||||||||

|---|---|---|---|---|---|---|---|---|

| Selection category listed on pesticide label |

A (dry and water-based) | B | C | D | E | F | G | H |

| Barrier laminate | High | High | High | High | High | High | High | High |

| Butyl rubber ≥14 mils | High | High | High | High | Slight | High | Slight | Slight |

| Nitrile rubber ≥14 mils | High | Slight | High | Moderate | High | High | Slight | Slight |

| Neoprene rubber* ≥14 mils | High | Slight | High | Moderate | High | Moderate | Slight | Slight |

| Natural rubber ≥14 mils | High | None | Moderate | None | Slight | Slight | None | None |

| Polyethylene | High | Slight | Moderate | None | None | None | None | None |

| Polyvinyl chloride (PVC) ≥14 mils | High | Slight | High | None | Moderate | Slight | None | None |

| Viton ≥14 mils | High | Slight | High | Slight | High | High | High | High |

| *Includes natural rubber blends and laminates. | ||||||||

| KEY: | ||||||||

| High: | Highly chemical resistant. Clean or replace PPE at end of each day’s work period. Rinse off pesticides at rest breaks. | |||||||

| Moderate: | Moderately chemical resistant. Clean or replace PPE within an hour of contact. | |||||||

| Slight: | Slightly chemical resistant. Clean or replace PPE within 10 minutes of contact. | |||||||

| None: | Not chemical resistant. Do not wear this type of material as PPE when contact is possible. | |||||||

Remember that waterproof gloves are not necessarily chemical resistant.

Chemical-resistant gloves with non-separate liners (i.e., flocking) are prohibited. You may wear shorter cotton gloves underneath the chemical-resistant ones, but they must be disposed of immediately upon contact with liquid. In addition, the cotton liners must be disposed of after 10 hours of use or within 24 hours from when they are first worn.

Never wear cotton, leather, or canvas gloves unless the label specifies that this type is required (e.g., aluminum phosphide fumigants).

— Can be one-piece, pull-on boots made of natural rubber, which may be coated with polyurethane, PVC, or blends, or you may use disposable or reusable shoe covers. Either way, pant legs should be worn outside of the boots to prevent pesticides from entering the footwear. Leather boots or canvas-leather sports shoes should never be worn when handling pesticides. Change shoes when you are finished spraying. Leave your contaminated footwear at work.

A chemical-resistant apron

— Hats must be a rubber-, PVC-, or plastic-coated safari-style, or wide-brimmed hat. Hoods must be rubber-, plastic-, or other barrier-coated hood. A full hood or helmet that is part of a respirator, like a PAPR, is also acceptable. Avoid cloth hats or liners that will absorb chemicals.

— May be required for mixing and loading pesticide spray tanks or for cleaning equipment. Aprons should be coated on both sides with the resistant material with edges sealed to prevent pesticide absorption and wicking. They should provide full protection of the front of the body from the neck to the knees. A chemical- resistant spray suit may be worn instead of an apron.

— Use the appropriate eye protection level when the label specifies the following:

Safety glasses

Safety glasses

Protective eyewear – Use safety glasses with brow, front, and temple protection; or a face shield; or fully-enclosed goggles; or a full-face respirator.

Chemical Goggles

Chemical Goggles

Goggles – Use fully-enclosed, chemical-splashresistant goggles or a full-face respirator.

A full-face respirator

A full-face respirator

Full-Face Respirator – You must use a tight-fitting, full-face respirator.

Safety glasses and a face shield

Eyewear must meet or exceed the current impact-resistance specification of the American National Standards Institute (ANSI Z87.1). Polycarbonate is lightweight and provides strong impact resistance and good chemical splash resistance. Wrap-around safety glasses are not acceptable for protection when spraying.

Note: Special goggles are made to wear over prescription glasses. Goggles must not interfere with the seal of a tight-fitting respirator. If you use a half-mask respirator, use goggles designed to fit over the nose-piece of your respirator.

Read before washing clothing worn while applying pesticides

All clothing worn while handling or applying pesticides is contaminated!

✔ Wash clothing before wearing again.

✔ Handle clothing with water-proof gloves.

✔ Rinse or soak first, using a hose or a bucket.

✔ Wash work clothes separately from family wash.

✔ Use detergent and hot water.

✔ Wash a few items at a time.

✔ Use highest water level.

✔ Use longest wash time.

✔ Line-dry in the sun, when possible.

✔ Throw away clothing that won’t wash clean.After washing — run machine through a complete cycle with detergent.

(Oregon OSHA 440-2858 (2/11/COM))

— Only use respirators approved by the National Institute of Occupational Safety and Health (NIOSH). When a pesticide label requires respirator use, it will commonly specify the NIOSH testing and certification (TC) number including the following types:

| NIOSH TC number |

Type of respirator | The pesticide label may specify this type of respirator for: |

|---|---|---|

| TC-84A- | Respirator with a particulate filter or with a combination chemical cartridge and particulate filter. | A pesticide product applied as a solid or a pesticide product in Toxicity Category I or II applied as a liquid with a vapor pressure lower than a certain value. |

| TC-23C- |

|

A pesticide product in Toxicity Category I or II applied as a liquid with a vapor pressure greater than a certain value. |

| TC-21C- | Powered air-purifying respirator (PAPR) with particulate filter. |

TC-84A-type air-purifying respirator (APR):

tight-fitting half mask with a combination Organic Vapor (OV) cartridge and N-95 particulate filter.

TC-23C-type air-purifying respirator (APR):

tight-fitting half mask with Organic Vapor cartridge.

TC-23C- or TC-21C-type:

Helmetstyle, battery-powered, air-purifying respirator (PAPR) TC number depends on type of cartridge/canister used.

Labels may also list which category of particulate filters (or pre-filters) can be used:

“N” (not resistant to oil – use only when no oil is present)

“R” (oil-resistant – can resist some oil, but only for a limited time)

“P” (oil-proof – can be used when oil is present)

Remember oil may also be present in stickers or surfactants found in spray mixes.

– Protection is dependent on proper airflow. A flow meter monitors airflow to determine if the canister or cartridge has become clogged. Follow the manufacturer’s recommendations; do not use the respirator if the airflow is less than the minimum required, typically four cubic feet per minute (cfm) for tight-fitting face pieces and six cfm for hoods or loose-fitting helmets. Batteries must be maintained for these respirators to operate properly. See the NIOSH fact sheet about PAPR batteries on Oregon OSHA’s “Respiratory protection” topic page. Opened PAPR canisters or cartridges must be replaced according to the schedule in the product information, even if minimum airflow is acceptable. Always write the date you opened the canister or cartridge on the package. Sealed canisters or cartridges may also have expiration dates that must be followed even if they have never been opened.

Air-purifying filters, canisters, and cartridges that are used more than once should always be stored separately from the other parts of the respirator and PPE to prevent contamination from pesticide residue.

The Worker Protection Standard (40 CFR 170) requires the following replacement schedule for respirator filters, canisters, and cartridges.

Replace filters used with particulate-filtering respirators:

Replace canisters or cartridges used with gas- or vapor-filtering respirators:

For more information, see “The Air You Breathe: Oregon OSHA’s Respiratory Protection Guide for Agricultural Employers.”

PPE should never be stored inside a pesticide storage room with the pesticides or other chemicals.

Oregon Occupational Safety & Health Division

Department of Consumer and Business Services

OR-OSHA 440-1018 (3/14)

For more information, contact the Oregon OSHA office nearest you or visit our website, www.orosha.org.

Salem Central Office

350 Winter St. NE, Rm. 430

Salem, OR 97301-3882

Phone: 503-378-3272

Toll-free: 800-922-2689

en Español: 800-843-8086

Fax: 503-947-7461

Portland

1750 NW Naito Parkway, Ste. 112

Portland, OR 97209-2533

Phone: 503-229-6193

Salem

1340 Tandem Ave., Ste. 160

Salem, OR 97301

Phone: 503-373-7819

Eugene

1140 Willagillespie, Ste. 42

Eugene, OR 97401-2101

Phone: 541-686-7913

Bend

Red Oaks Square

1230 NE Third St., Ste. A-115

Bend, OR 97701-4374

Phone: 541-388-6068

Medford

1840 Barnett Road, Ste. D

Medford, OR 97504-8250

Phone: 541-776-6016

Pendleton

200 SE Hailey Ave.

Pendleton, OR 97801-3056

Phone: 541-276-9175

Publication #: OR-OSHA 440-1018 (3/14)

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More