The dairy industry has dramatically changed in recent years. New processing technologies, shifts in consumers’ preferences, and changes in economic conditions have changed the way dairies operate. It is undeniable that the forces of the economy have pushed increased efficiency in animal production. In their efforts to lower per-unit production costs, small-scale operations are becoming fewer in number, and more cost-effective large-scale operations are increasing so that there are fewer, but larger, dairies.

At the same time that the concentration of animals is increasing, there has been a decrease in the number of workers employed. Increasing the number of animals per worker may increase workers’ risk of injury and illness. Injuries and illnesses on the job are costly and damaging – both for the individual employee who gets hurt and for your dairy.

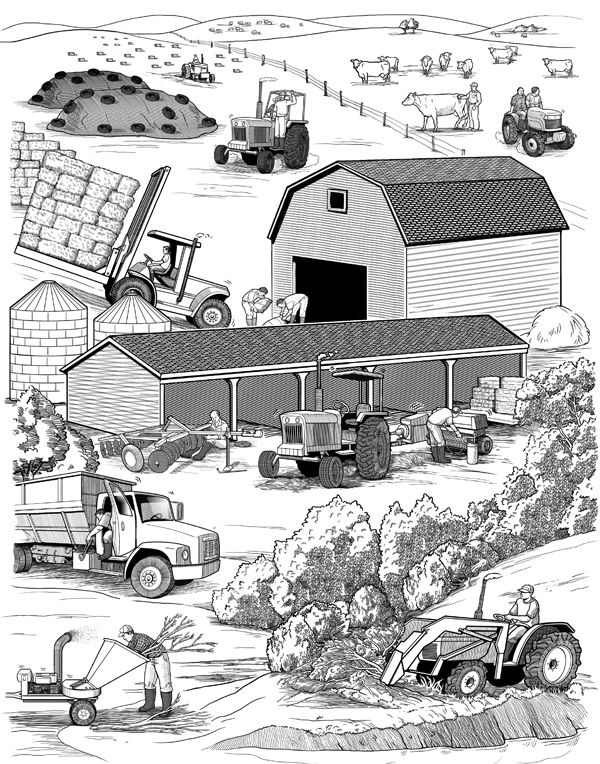

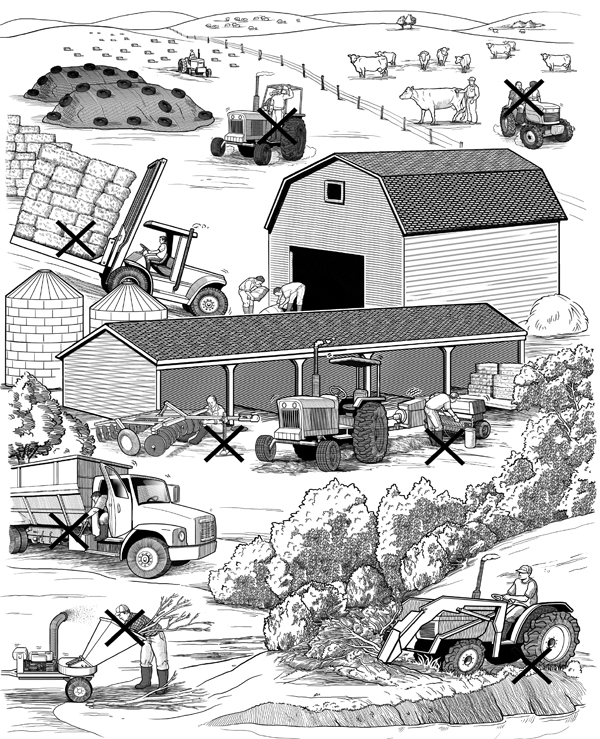

Recent research studies show that the two main causes of workers’ injuries (fatal and non-fatal) are incidents with machinery and animals (Mitloehner and Calvo 2008). Machine-related accidents include tractor rollovers, being run over by tractors and being entangled in rotating shafts. Animal-related injuries include kicks, and workers being pinned between animals and fixed objects. Other causes of injuries include chemical hazards, confined spaces, manure lagoons, use of power tools, and improper use or lack of personal protective equipment.

It is the responsibility of the employer to provide a safe workplace to all employees, by setting up the worksite as safely as possible. Employees also have a responsibility to follow safety rules. Employers should have safe, wellmaintained equipment; enforce safe work practices; provide protective gear when necessary; and train employees about the hazards they face and how to work safely. At the end of this guide, you will find useful background information on how to take the safest approach, and what components your health and safety program should have.

This Dairy Safety Training Program will help strengthen your health and safety program by helping you teach your employees about hazards they face to reduce the chance of injury.

It is not enough to just tell employees to “be more careful” to avoid injury or illness. To stay safe on the job, staff (especially new employees and younger employees) need:

The Dairy Safety Training Program is designed specifically for dairy owners and managers who need to train employees working in dairies. This training program can help:

The cost of workers’ compensation for the dairy industry is about three times the average cost of workers’ compensation in California, according to the Workers’ Compensation Insurance Rating Bureau.

Reduce the number of days away from work and lost productivity. The best way to reduce costs, retain jobs and maintain a productive workforce is to reduce injuries.

This training guide is designed to be used by owners and managers. It contains step-by-step instructions for conducting the training sessions and background information and resources for owners and managers. In addition to the materials provided in this guide, the California Worker Occupational Safety and Health Training and Education Program (WOSHTEP) also has available Heat Hazards in Agriculture: A Guide for Employees to Carry Out Tailgate Training. This free guide can be obtained from the WOSHTEP Resource Centers. See the resources section of this guide for information.

The training methods used in this guide are participatory. Research shows that when people are actively engaged in their own learning by discussing, problem-solving, and practicing new skills through hands-on activities, they are more motivated to participate and committed to supporting best practices.

The Dairy Safety Training Program materials are available in English and Spanish.

A good health and safety program is built on management commitment and employees’ involvement.

Regular health and safety training for employees is one of the best strategies to prevent job injuries and illnesses.

What is in the Training Session

The five training sessions (approximately 30-minutes each) address some of the most common hazards in the dairy industry. The topics are listed below:

For each of the sessions you will find:

Remember to document all trainings by recording the date, topic, name of the trainer, and names of the employees. If you have fewer than 10 employees, just keep a log of the instructions provided to each employee.

When to Conduct the Trainings

It is best to conduct the training program when employees are first hired. Failing to train workers before they are exposed to hazards in the workplace might result not only in a violation of Cal/ OSHA’s rules, but also in a serious or fatal accident. For existing employees, you may wish to hold the short training sessions spread out over several weeks. This gives employees an opportunity to absorb the information. If this is not possible, you can hold a single training session covering all the topics at once.

How to Maximize Employee Participation

It is best to conduct the training sessions in groups (2 to 25 employees) to foster discussion and exchange ideas. Whether your training sessions are held in a group or one-on-one, encourage employees to speak up about their concerns. Involving your employees in identifying potential problems is an effective way to get employee buy-in regarding the importance of health and safety. Also, encourage employees to offer suggestions to improve health and safety. Since they are doing the work day-to-day, they know what works and what does not. They may also have ideas that can be shared with other employees.

At the end of this session, participants will be able to:

Materials Needed:

In our next session, we will talk about how we do things here at this worksite to reduce hazards and to keep you from getting injured. We want you, the employees, to always be thinking about how to make things safer. In dairy work, it is impossible to eliminate all hazards, but there is a lot that can be done to make things safer. Here is what we are looking for:

| Potential Hazards | ||

|---|---|---|

| Machinery | Animal | Other |

|

|

|

Note to the Instructor:

There are many ways to find the hazards in a workplace. One useful tool is to create a hazard map. To create a hazard map, make a simple drawing of the dairy’s floor plan and have employees mark all the spots where there is a hazard or potential hazard. You can schedule a session to go over the list of hazards created by the group and then locate them in the map. For tips on how to create a hazard map, contact your WOSHTEP Resource Center. (See the resource section of this guide for contact information.)

If necessary, you can schedule two Controlling Hazards sessions.

At the end of this session, participants will be able to:

Materials Needed:

Select three to four case studies to review during the 30-minute session. There are seven case studies included in this session. The cases are based on real dairy accidents. Because we try to limit the duration of each session to around 30 minutes, we suggest you select three or four case studies to allow enough time for participants to discuss each case in detail. However, it may be a good idea to conduct two sessions focused on controlling hazards so participants have an opportunity to learn from all of the cases.

It was late Friday afternoon when Isaac was finishing up feeding the calves and making sure the hutch doors were closed. He was working quickly because it was getting late. While closing one of the last doors, Isaac’s finger was cut on a door handle that had a sharp, rusty edge. Other workers had torn their clothes and scratched their arms on the door handle in the past, but this time, Isaac’s finger was cut badly. Because he was almost finished with the job, he just wrapped his finger with a napkin and continued working. He did not clean his finger until he got home, where he washed it well. The following Monday, Isaac could not move his finger and his whole hand was swollen. When he arrived at the dairy the next day, his supervisor sent him to the hospital. The doctor told Isaac that his finger was severely infected. He was admitted for an I-V antibiotic treatment every eight hours for three days.

Let participants respond and then make sure all of the following points are covered.

(You may write the group’s answers on the flip chart paper.)

Note:

Ramiro was inside the extended bucket of a John Deer front-end loader, approximately 10 feet above ground level, removing the twine holding down the protective tarp of a haystack. He was cutting one of the lines holding down the tarp when a bale above him began to fall from about 20 feet. The loader operator moved the tractor backwards as Ramiro turned his body away from the falling bale. The bale pinned Ramiro against the rear bar of the bucket causing serious injuries to his abdomen.

Let participants respond and then make sure all of the following points are covered.

(You may write

the group’s answers on the flip chart paper.)

Note:

Peter had been trimming the trees around the property using a chainsaw since early in the morning. At around 1:30 p.m., Peter was working in one of the tallest trees, with one of his legs on a ladder step and the other on one of the branches. Suddenly, the branch snapped, twisting and pinning him against the tree. After two other employees rescued him, Peter was hospitalized for severe internal injuries.

Let participants respond and then make sure all of the following points are covered. (You may write the group’s answers on the flip chart paper.)

Note: See http://www.dir.ca.gov/Title83421.html and http://www.dir.ca.gov/Title8/3427.html

Greg, a lifelong dairy farmer, was fixing an area of the fence that had been damaged by a storm. Helping him was Oscar, a young worker who was hired a few days earlier. Greg went to the truck to drink some water and left Oscar standing outside the fence removing some old nails from a post. Oscar was having trouble removing one of the nails, so he jumped over the fence to get a better grasp and pull out the nail. While Oscar’s back was turned away from the animals, a bull ran toward him, ramming Oscar against the fence. Oscar fell but managed to scramble back under the gate before the bull attacked him again. Oscar had several bruises and three broken ribs. He spent a week at the hospital and it took him six months to be able to go back to work.

Let participants respond and then make sure all of the following points are covered.

(You may write the group’s answers on the flip chart paper.)

David was hauling manure from a pit to a small field not far from the farmhouse. He was shortstaffed but anxious to complete this task before the sun went down. He had worked since early morning and even skipped lunch to finish as soon as possible. During the hauling, David had to maneuver his tractor down a slight incline to get the manure spreader in the right position to load the manure from the barnyard. By mid-afternoon, David had taken approximately 25 loads to the field and was eager to finish clearing up the pit, so he speeded the tractor up a bit. David was returning back up the slight incline to position the manure spreader, when the tractor turned over, pinning him under the rear fender. Both his legs were broken and he could not work around the dairy for more than 8 weeks.

Let participants respond and then make sure all of the following points are covered.

(You may write the group’s answers on the flip chart paper.)

Note: See http://www.dir.ca.gov/Title8/3441.html http://www.dir.ca.gov/Title8/3651.html

Let participants respond and then make sure all of the following points are covered.

(You may write the group’s answers on the flip chart paper.)

Note: Natural decomposition of waste materials causes a decrease in the oxygen levels at the same time it produces other (potentially deadly) gasses such as methane, ammonia and cyanide. Even a very brief entry can be fatal. Previous successful entries are NOT an indicator that it will be safe to enter the next time. Always monitor the air first and use appropriate personal protective equipment!

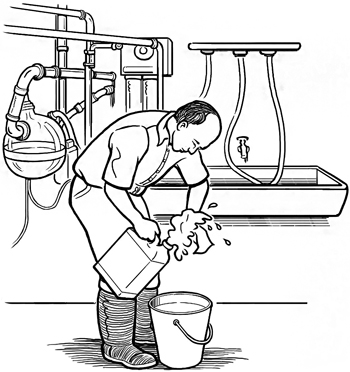

John was cleaning the milking equipment before milking the cows. This was the first time he had performed this task; however, he had seen his co-worker do it every day for more than a month. John was refilling the cleaning solution when suddenly it splashed onto his chest and arm causing a burning sensation. He rushed to rinse it off with water but had to be taken to the hospital, where he received treatment.

Let participants respond and then make sure all of the following points are covered.

(You may write the group’s answers on the flip chart paper.)

Note: An eyewash and/or emergency shower should be available in the immediate work area if the chemicals used are corrosive.

Let participants respond and then make sure all of the following points are covered. (You may write the group’s answers on the flip chart paper.)

Note: Before using chemicals, learn all you can about them (how to use them properly, potential health hazards, and how to dispose of used containers). Companies that make chemical products must write up information sheets, called an MSDS (material safety data sheet). They send the information sheets to the companies and others that use their products. MSDSs tell you what is in the product, how it can harm you, and how to protect yourself, including what kind of gloves, goggles, or other protective gear to wear.

At the end of this session, participants will be able to:

Materials Needed:

Familiarize yourself with the activity sheet and make enough copies. One copy per participant.

| Hazard | What could happen? | What could be done to reduce or eliminate the hazard? |

|---|---|---|

| There are two workers on top of the small tractor sharing the only available seat. |

|

|

| Worker is driving a forklift up a small hill with the fork up and loaded. |

|

|

| Worker is clearing debris close to irrigation canal. Tractor clearing debris does not have ROPS (roll over protection system). |

|

|

| Worker changing a tractor’s disc is using a bumper style jack to support the tongue of the disc. |

|

|

| A worker is riding on the access platform (tractor is equipped with ROPS). |

|

|

| Worker is shredding some branches with half his body leaning inside the funnel. |

|

|

| Mechanic is oiling a hay bailer while it is running. |

|

|

| A worker is reaching to remove a clog from wagon‘s chain while the wagon is running. |

|

|

Uncontrolled energy causing the sudden and unexpected movement of equipment and/or machinery can kill or injure you!

The OSHA standard for the control of hazardous energy, better known as “Lock-out/Tag-out” (Title 29, Code of Federal Regulations, Part 1910.147) refers to specific practices and procedures to safeguard employees from the unexpected startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities. In addition, Part 1910.333 sets forth requirements to protect employees working on electric circuits and equipment.

If your work involves activities such as set-up, un-jamming, repairing, cleaning, servicing and adjusting equipment and/or machinery, it is important to consider the following:

The Lockout/Tagout standard establishes the following requirements to employers:

For more information, go to www.dir.ca.gov

At the end of this session, participants will be able to:

Materials Needed

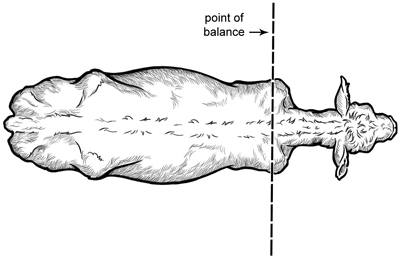

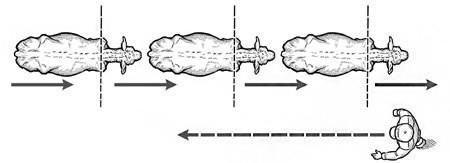

Pablo is a young worker. During his first week working at a dairy, he hurt his arm while helping move some cows. José, an experienced worker, realizes Pablo needs more training. After getting Pablo aid for his injury, José reviews four basic principles that make working around cattle safer for the worker: (1) the blind spot; (2) the flight zone; (3) signs of stress; and (4) the point of balance.

Animals tend to walk in the opposite direction of the handler. The point of balance is at the animal's shoulder. Animals move forward if the handler stands behind the point of balance. They will move back if the handler stands in front of the point of balance. It is not necessary to prod animals; they will move by themselves when the handler walks past the point of balance, in the opposite direction of the animals. If the animals are moving by themselves through the chute, leave them alone. You may occasionally tap the side of the chute to keep them moving.

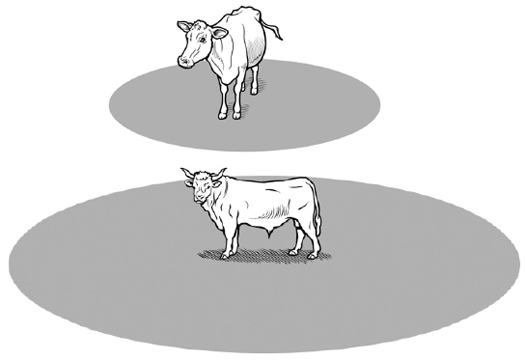

The flight zone is the animal’s personal space; it is an imaginary area within which the animal feels safe. The size of the flight zone is determined by the animal. A completely tame animal will have no flight zone and can be approached and even touched. The more untamed the animal is, the larger its flight zone will be. Bulls usually have larger flight zones than cows.

Usually, animals will start to move away when the handler enters their flight zone.

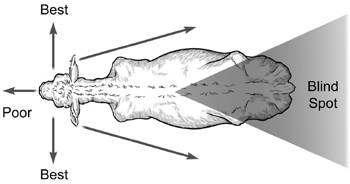

While humans can see only within 180 degrees, cattle have panoramic vision and can see 300 degrees. Their wide-angle vision enables them to see around them without turning their heads except for a small point directly behind their rear. This point is called the blind spot.

Panoramic vision causes everything to appear bent and distorted. Cows also have poor depth perception and may be fearful of shadows or dark areas; shadows may look like holes to them. To better focus their view in front of them, cattle will lower their heads for a closer examination.

Always approach a cow/bull from the shoulder and speak calmly as you approach.

Remember to never approach cattle from behind, even if it is a tame animal. A startled cow may kick you.

| Signs of Stress | |

|---|---|

| Ears pointing | Tail tucked between legs |

| Looking sick or hurt | Looking afraid |

| Butting | Neck curved |

| Bellowing | Shaking head |

| Kicking | Pawing |

| Displaying broadside view | Snorting |

| Raised ears | Flicking or raised tail |

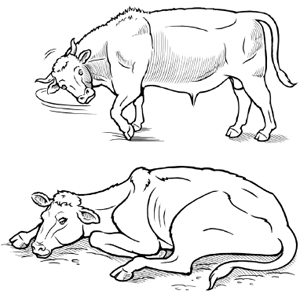

| When working with cattle, it pays to keep calm and be patient, slow down, work quietly, and use common sense. | |

| Avoid excessive noise. It is easier to work around non-stressed animals. In addition, milk production increases when animals are calm. | |

| Cows/bulls are herd animals; this herding instinct provides a sense of safety. Singling animals out causes them anxiety. As they feel safer in groups, take advantage of this natural instinct by working from the front of the group; the others will follow the lead. | |

| Generally, cattle are gentle animals; however, a stressed animal may cause you harm. When an animal feels threatened, it may kick, push, bite or attack. Staying alert at all times and following good handling practices will reduce your chances of injury. | |

(This part of the session can be scheduled on a different day)

Before starting the demonstration:

At the end of this session, participants will be able to:

An emergency at work is something hazardous that is not planned – it is unexpected. It can be very serious and may cause a great deal of harm to employees or the public. It may also cause damage to the workplace itself. Emergencies may be natural events or man-made.

Some of their answers may be:

Note to instructor: After the answers are discussed, tell the group what procedures they should follow in different emergencies they may face.

Taking risks is part of running a successful business; you take financial risks when you purchase new equipment, grow your herd, or make changes in your marketing to stay competitive. But some risks are just not worth the gamble. One of these is risking the safety and health of those who work for you. By implementing a strong safety and health program, you can accomplish three important things at once: prevent human suffering; save money; and promote a positive image.

Every dollar invested in workplace safety results in $3 or more in savings. Safety is an investment, not a cost. —Insurance industry study

One serious injury in your workplace can have a devastating impact on your employees, their families and you. By preventing that serious accident, you can help to:

For every dollar spent on the direct costs of a worker’s injury or illness (medical expenses and lost wages), it is estimated that you, the employer, will spend at least as much again to cover the indirect and hidden costs. In most cases, you may spend four to six times more. Consider what one injury with lost workdays would cost you in terms of:

An effective health and safety program can also make your business stand out. It can:

A big accident or fine may be a rare event, but it can cost a great deal in terms of public image. We had a disastrous experience with OSHA and paid dearly for it. We never want to be embarrassed like that again. —Safety Manager

American Society of Safety Engineers. White Paper: The return on investment for safety, health and environmental management programs. Des Plaines, IL, ASSE, 2002. McDonald, C. Workplace safety pays, survey shows, National Underwriter, Sept. 17, 2001:105, 38:ABI/INFORM Global pg 26. Schulte, P.A. Characterizing the burden of occupational injury and disease. Journal of Occupational and Environmental Medicine, 47(6):607-622, June 2005.

Portions of this factsheet were adapted from the Guide to Developing Your Workplace Injury and Illness Prevention Program, Cal/OSHA Consultation, rev. 2005.

Many hazards exist in the dairy industry, and steps can be taken to improve safety dramatically. As the safety pyramid below shows, there are three main ways to protect workers.

Many hazards exist in the dairy industry, and steps can be taken to improve safety dramatically. As the safety pyramid below shows, there are three main ways to protect workers.

The best way to prevent injuries is to remove the hazard altogether (#1 below), or keep it isolated, away from workers, so it cannot hurt anyone. This way the workplace itself is safer.

Removing the hazard can sometimes be the most difficult solution, or take the longest time to implement. You may need other solutions to protect you in the meantime. These include improving work practices (#2) and using protective clothing and equipment (#3).

Chemicals like milking equipment cleaners can splash into a worker’s eyes. What controls can be put in place to keep workers from getting hurt?

The laws and regulations cited in this booklet are available on line.

This Dairy Safety Training Program can help you provide basic health and safety training to your employees, but additional training may be required. An overview of training requirements under the Injury and Illness Prevention Program (IIPP) standard, Hazard Communication standard, Emergency Action Plan standard, and other Cal/OSHA standards follows.

All California employers are required to provide health and safety training to all of their employees. The broadest training requirements fall under Cal/OSHA’s Injury and Illness Prevention Program (IIPP) standard (required under California Labor Code -Section 6401.7. See http://www.dir.ca.gov/ Title8/3203.html). Training must be provided to all workers on the hazards in your workplace:

Two other standards that affect most workers are Cal/OSHA’s Hazard Communication standard, which requires training on any chemicals to which employees may be exposed, including cleaning products, and the Emergency Action Plan standard (this standard is not mandated for dairy operations, but if you have one, it has to meet the standard, and these procedures may be incorporated into your Illness and Injury Prevention Program). These three standards are summarized in this section. However, this booklet is not designed to ensure full compliance with all Cal/OSHA standards, so be sure to check the relevant standards yourself, as needed.

Cal/OSHA requires training for other specific standards, such as fall protection, forklifts, and hearing protection. To find out which training requirements affect your employees, go to: www.dir.ca.gov/dosh/dosh_publications/TrainingReq.htm

Employees also need bloodborne pathogen training if they are at risk of coming into contact with human blood or other potentially infectious materials. For more information, go to: www.dir.ca.gov/dosh/dosh_publications/dontrisk.html

The Injury and Illness Prevention Program (IIPP) standard requires every California employer to establish, implement, and maintain an effective IIPP to promote health and safety in the workplace.

An IIPP must be a written plan that includes all of the following elements:

The written IIPP must be made available to all workers. Records must be kept to document that there is an effective program in place. These records must include scheduled inspections, actions taken to correct problems, and types, dates, and providers of training. Please note that while all employers need to have written IIPPs, there are some exceptions to the documentation requirements if you have fewer than 10 employees.

See the Resources section for more information on writing an IIPPs.

This Cal/OSHA regulation requires employers to provide information to employees about the chemicals and other hazardous substances to which they may be exposed at work by providing Material Safety Data Sheets (MSDSs), chemical labels, and training.

MSDS. Manufacturers of products containing hazardous ingredients must prepare MSDSs for those products and distribute them to purchasers (such as employers). The MSDS identifies the manufacturer, contents, toxicity, and safety hazards of the chemical product. It describes routes of exposure (skin, inhalation, or ingestion) and explains how to prevent health problems. Employers must have an up-to-date MSDS for each hazardous product they use and must make MSDSs available to employees. Employers can get MSDSs by calling their chemical supplier, or, in some cases, from the Internet. Some MSDSs are available in several languages.

Chemical Labels. Employers must make sure that all products with hazardous ingredients are properly labeled. Original labels must include the identity of the hazardous substance (matching the corresponding MSDS), appropriate hazard warnings, and the name and address of the manufacturer or importer. This labeling requirement applies to all containers, even those into which a smaller amount of the chemical has been poured.

Training. Employers are required to train workers about the hazardous substances used at work, their health effects, how to work safely with them, how to read an MSDS, and where the MSDSs are kept. The training must also cover how accidental chemical releases are detected and what emergency procedures should be followed in case of a spill or leak.

Employers are required to describe in writing the elements of the workplace’s hazard communication program and how the workplace will comply with this Cal/OSHA standard. This written program must be available at the worksite and communicated to all affected workers.

Note: This standard is not mandated for dairy industry operations, but if you have one, it has to meet the standard.

This Cal/OSHA regulation sets minimum requirements for Emergency Action Plans, such as evacuation plans. It requires employers with more than 10 employees to have such a plan in writing.

Employers with 10 or fewer employees do not need to have a written plan, but they do need to meet all the other requirements of the Emergency Action Plan and must communicate these elements to employees. Regardless, it is a good idea to plan for emergencies.

The Emergency Action Plan must include the following elements:

Alarm system. The employer must have an alarm system that can be seen, heard, and understood by all employees.

Evacuation. The plan should designate inside shelters, exits, evacuation routes and procedures, and outside meeting places. Exits and evacuation routes should be checked periodically to be sure they are not blocked.

Training. The employer must designate and train key staff to assist in evacuation procedures. All employees need to understand what to do during different kinds of emergencies. Employees should be trained so that they understand their responsibilities during an emergency; the alarm system and “all clear” announcements; where to gather during an emergency; how to report an emergency; what to do if there is a chemical spill; and who has training in first aid and training in the use of fire extinguishers.

Cal/OSHA is the California state program responsible for protecting the health and safety of workers. Cal/OSHA makes sure that employers follow occupational safety and health regulations and keep the workplace safe.

All non-federal workers in California are protected by Cal/OSHA regulations (often called standards). This includes public employees and immigrant workers who are not legally authorized to work in California.

Employers must:

The Cal/OSHA Consultation Service provides free technical assistance to employers on health and safety issues. Consulting services include on-site visits (no fee), assistance in complying with Cal/ OSHA standards, educational seminars, and publications.

See the Resources section for information on how to contact Cal/OSHA and Cal/OSHA Consultation Services.

If you hire teenagers, you need to know that there are special laws related to teen work. Here’s what you can do to prevent injuries to your teen workers. The measures you take to keep teens safe will help protect all employees. Here are six steps to safer teen jobs:

Child labor laws restrict the kinds of work teens under the age of 16 can do in agriculture, with even further restrictions for youth under 12. Youth of any age may work at any job, at any time on a farm owned or operated by their parents. However, children under 12 may not work near: 1) moving farm equipment; 2) pesticides or other chemicals; or 3) water hazards, such as irrigation canals.

In California no worker under 16 may: 1) handle or apply pesticides; 2)drive, ride or assist in operating a tractor or forklift; 3)drive any vehicle for transporting passengers; 4)use powered equipment such as a chain saw, hay mower, hay baler or cotton picker; 5)work on a ladder over 20 feet; or 6)work inside a silo.

This table shows the hours that teens may work in California.

Some school districts may have more restrictive regulations. Also, there are some exceptions for teens in Work Experience Education programs.

Work Hours for Teens |

||

|---|---|---|

| Ages 12-15 | Ages 16-17 | |

| Work Hours | Not before 7 a.m. or after 7 p.m. during the school year Not during school hours 7 a.m. to 9 p.m. during the summer |

Not before 5 a.m. or after 10 p.m. on school nights Not before 5 a.m. or after 12:30 a.m. when there is no school the next day |

| Maximum Hours When School is in Session | 18 hours a week, but not over:

|

48 hours a week, but not over:

|

| Maximum Hours When School is Not in Session |

|

|

For more information on employing teens, visit the Young Workers Safety Website at www.youngworkers.org.

Adults learn best when the training:

Tell me, I forget. Show me, I remember. Involve me, I understand. —Anonymous

Cal/OSHA Guide to Developing Your Workplace Injury and Illness Prevention Program (IIPP)

This manual describes the employer’s responsibilities in establishing, implementing, and maintaining an IIPP (see page 38). It also outlines steps that can be taken to develop an effective program that helps assure the safety and health of employees on the job. The manual includes checklists for selfinspection. To obtain a copy of the manual, contact your local Cal/OSHA area office, call Cal/OSHA Consultation at (800) 963-9424, or download it at: www.dir.ca.gov/dosh/dosh_publications/iipp.html

Resources from Your Workers’ Compensation Insurance Broker

Most workers’ compensation insurers offer loss control assistance, including help with putting together your IIPP. Contact your insurance broker to find out what resources may be available from your insurance company. You can also download a sample IIPP from the State Compensation Insurance Fund (SCIF) Web site at: www.scif.com/safety/IIPP.html

Other Web Resources

Many private companies offer online programs for a fee (at least $100), with step-by-step instructions to guide you through the process of developing your IIPP. You can search for these programs online. Make sure they are in compliance with California laws.

Cal/OSHA Guide to the Hazard Communication Regulation

This guide describes the employer’s responsibilities in establishing, implementing, and maintaining a Hazard Communication Program (see page 39). Contact your local Cal/OSHA area office for a copy, or download it at: www.dir.ca.gov/dosh/dosh_publications/hazcom.pdf

Federal Occupational Safety and Health Administration (OSHA) Evacuation Plans and Procedures eTool

This eTool will help small, low-hazard service or retail businesses implement an Emergency Action Plan, and comply with OSHA’s emergency standards. Download it at: www.osha.gov/SLTC/etools/evacuation/index.html

Cal/OSHA Consultation Service

The Cal/OSHA Consultation Service provides technical assistance to employers on health and safety issues. Consulting services include free on-site visits, assistance in complying with Cal/OSHA standards, educational seminars, and publications.

The Consultation Service is separate from the Cal/OSHA Enforcement Unit, and consultants are not involved with enforcement activities such as inspections, citations, and fines. All communications between the employer and the Consultation Service are confidential and are not shared with enforcement staff. In exchange for this free consultation, however, employers must agree to correct in a timely manner any serious hazards that are identified.

Cal/OSHA publications provide information about Cal/OSHA programs, standards, and general health and safety topics. Various types of guidelines and model IIPP plans also are available. You can obtain copies of Cal/OSHA publications by phoning (800) 963-9424 or from their Web site: www.dir.ca.gov/dosh/consultation.html

U.S. Small Business Administration

This site is the official business link to the U.S. government, managed by the U.S. Small Business Administration (SBA). It provides a single access point to government services and information to help the nation’s businesses with their operations and includes workplace health and safety information. Go to: www.business.gov/topic/ Workplace_Health_and_Safety

California Department of Public Health, Occupational Health Branch, Employer Resource Links

This site has links to various resources to help small business owners, including health and safety factsheets and other educational materials. Call OHB at (510) 620-5757, or go to: www.cdph.ca.gov/HealthInfo/ workplace/Pages/EmployerLinks.aspx

Federal Occupational Safety and Health Administration (OSHA) eTools

OSHA’s eTools are “stand-alone,” interactive, web-based training tools on occupational safety and health topics. They are highly illustrated and utilize graphic menus. Some also allow the user to ask questions and receive reliable advice on how OSHA regulations apply to their workplace. This site also has links to specific safety topics. Go to: www.osha.gov/dts/osta/oshasoft/index.html

Federal OSHA Small Business Outreach Training Program

This online guide contains links to basic information about selected topics in occupational safety and health, specifically focusing on the needs of small business. Go to: www.osha.gov/dcsp/smallbusiness/index.html

National Institute for Occupational Safety and Health (NIOSH), Safety and Health Resource Guide for Small Businesses

This guide is intended to help small business owners, employers, and managers deal with occupational safety and health concerns. It contains telephone numbers, e-mail and Internet addresses, and mailing information that will connect small businesses to government agencies, private organizations, consultants, and others who can help with occupational safety and health issues. You can also click on the “NIOSH topics” button for a comprehensive alphabetical list of NIOSH health and safety information and materials. Go to: https://www.cdc.gov/niosh/topics/smbus/guide/

North Carolina State University, Safety and Health Management Systems for Small Businesses

This is a free, online training course, funded by an OSHA-sponsored grant and developed by North Carolina State University, designed to assist small and medium-sized businesses in developing and implementing an effective safety and health management system. Go to: https://osha.ies.ncsu.edu/index.cfm?

California Commission on Health and Safety and Workers’ Compensation (CHSWC). Worker Occupational Safety and Health Training and Education Program (WOSHTEP), California Resource Centers

The WOSHTEP Resource Centers provide written materials, including factsheets, brochures, pamphlets, books, and reports. The Resource Centers also offer technical assistance, research assistance, and referrals to state and local health and safety agencies. WOSHTEP staff also offers free 24-hour classes that prepare workers to become Worker Occupational Safety and Health (WOSH) Specialists, health and safety awareness classes, Young Worker Leadership Academies, and resources and training for small businesses. www.dir.ca.gov/chswc

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More