In 2011, seven loggers doing cable yarding work were injured or killed because they were not in the clear, when standing too close to the turn and rigging – including lines, chokers, butt rigging, and carriages.

January 2011 –A choker setter and a rigging slinger were pre-setting and hot-setting turns of logs. They had set a turn of logs near the cable lines, and the rigging slinger retreated to a logged-off area to the south. The choker setter retreated to the north side of the lines, dropping his chokers near logs to be choked, and moved further out of the way. The turn hung-up, and a log upended and struck the choker setter who had returned to the chokers.

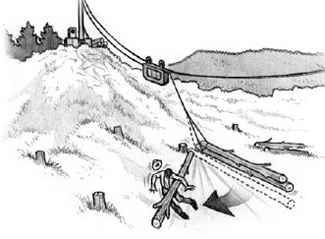

January 2011 –A choker setter and a rigging slinger were pre-setting and hot-setting turns of logs. They had set a turn of logs near the cable lines, and the rigging slinger retreated to a logged-off area to the south. The choker setter retreated to the north side of the lines, dropping his chokers near logs to be choked, and moved further out of the way. The turn hung-up, and a log upended and struck the choker setter who had returned to the chokers. All these victims were too close to the rigging and not standing in the clear while the work was under way. Oregon OSHA defines in the clear as “a position within the work area where the probability of hazardous contact with vehicles, machines, falling trees, moving logs, rootwads, chunks, material, rigging, and equipment is minimized by distance from the hazards or use of physical barriers, such as stumps, trees, terrain, or other objects providing protection.”

Plan the work and control hazards. All operations at a logging site must be planned, and the supervisor must evaluate and control potential hazards before work begins. Hold pre-work safety meetings to discuss site conditions and hazards. Determine which logging method affords the best opportunity for the rigging crew to get in the clear.

Know what “in the clear” means. Before giving the “go-ahead” signal on a turn, all rigging crew members must move to an area that is in the clear by moving to the side and behind all the logs in the turn. The person in charge of the rigging crew must be a competent person and know where “in the clear” is for any given situation.

You are not in the clear unless you are out of the swing radius of the longest log in the turn. This means the length of the log, plus the length of the choker, plus any line deflection that could occur, plus a safety factor (a few extra steps you should always take to be sure you’re safe).

Don’t be complacent! Remember, you’re not working in an office. When you work in the woods beware of your surroundings and anything the turn could move or roll toward you, and stay out of the bight of lines under tension. The decisions you make can affect your life.

Don’t take chances! Many loggers have died because they or their supervisors took a chance with their safety. Don’t leave to chance something you have the ability to control. If you take chances in the woods, you can lose your life.

Watch out for one another. Your co-workers rely on you for their safety as you rely on them. Bring to their attention any unsafe conditions you see.

Supervisors, heads up! Never forget that the safety of those you supervise is your first priority. Inexperienced workers rely on you for their survival, and your actions reflect the safety values of the company.

Hazard alerts provide information on hazardous materials, equipment, or practices.

For more information contact the Oregon OSHA Standard and Technical Resources Section at 503-378-3272,

toll-free at 800-922-2689, or visit our website at www.orosha.org.

Publication #: OR-OSHA 2993-28 (6/12)

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More