SPECIAL ALERT – hung limbs and snags in trees are a recurring contributing factor to occupational fatalities among tree fallers in Oregon.

SUMMARY

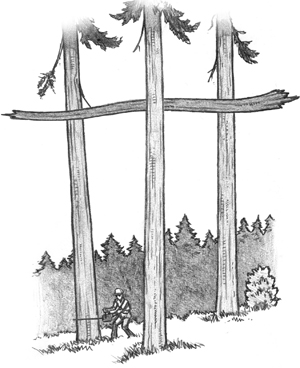

On December 29, 2011, a 41-year-old Hispanic male was killed while working as a timber faller. The incident occurred at about 1pm on a workday. The victim, working as a lone faller, was attempting to fell a tree that had an alder limb hung up in it. The alder limb was approximately 34 feet in length and 11 inches in diameter. The victim’s cutting partner was working on a separate strip of timber approximately 400 to 500 feet away. Witness accounts state that they had observed the hung alder limb in the victim’s cutting strip about two hours prior to the incident (see Figure at right). The victim was found underneath the alder limb and was pronounced dead at the scene.

RECOMMENDATIONS

OR-FACE supports the prioritization of safety interventions using a hierarchy of safety controls, where top priorities are hazard elimination or substitution, followed by engineering controls, administrative controls (including training and work practices), and personal protective equipment.

Illustration of the victim working under an

alder tree limb hung up in Douglas-fir trees

(cased on witness descriptions of the scene).

On the day of the incident, the victim was working as a timber faller and was killed when a hung limb fell and struck him. While witnesses had observed the hung limb in the worker’s cutting strip, no coworkers witnessed the fatal incident directly. OR-FACE became aware of the event after notification from OR-OSHA. This report is based on information contained in the OROSHA investigation as well as an OR-FACE interview with the owner of the company who was present at the worksite on the day of the incident.

The victim’s employer was a small logging contractor that provides timber falling and logging services. The company employs 10 to 12 full time workers on a year round basis. The victim had 15 years of logging experience working for this employer. The victim started out as a choker setter, working up to fell small areas of trees and then on to be a timber faller. The victim had worked for 2 years as a timber faller with the first year working side by side with an experienced timber faller. The victim was considered an extremely hard worker and a good employee of the company. He was originally from Mexico and spoke Spanish as his native language. Coworkers believed that the victim’s limited English speaking abilities in the past had prevented the victim from becoming a timber faller sooner in his career. The training received by the victim was given in English. The company owner felt that his understanding of the English language was adequate for the training being provided.

The employer conducted regular safety meetings with the crew, with the most recent pre-job safety meeting occurring two weeks prior to this incident. In prior safety meetings the employer had discussed the hazards of working under hang-ups and the company policy not to work under hang-ups. It was company policy that in such hazardous situations, employees should seek the assistance of their cutting partners before commencing work to alleviate the hazard. Just one day prior to the incident the victim’s cutting partner had modeled this practice by requesting assistance from the victim with a hazardous situation. Prior to the commencement of cutting the unit involved in the incident, the company had conducted a pre-job site inspection and no hung trees or hung limbs were identified. The company also conducted random safety inspections, and had conducted one 2 days prior to the incident.

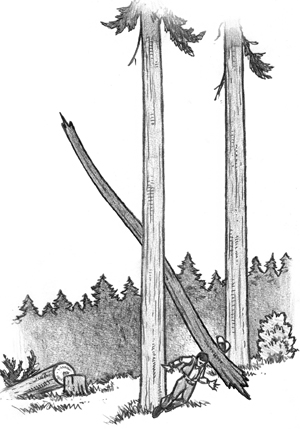

Illustration of the victim struck by the hung

alder tree limb he was working under (based

on witness descriptions of the scene).

The area where the fatal incident occurred was gentle in slope (approximately 35 to 40% grade), with Douglas-fir as the predominant species intermixed with clumps of Maple trees and other less prevalent species, including alder. The Douglas-firs averaged 20 inches in diameter on the stump and 2.5 logs per tree. The 60-acre unit was to be felled and bucked while leaving the top of each tree attached. The incident occurred during the second week the victim was working at this logging site.

At about 11:00am on the day of the incident, a coworker observed that an alder tree in the victim’s strip had been knocked to the point where one of its limbs broke off and had lodged itself 30 feet above ground in some adjacent trees. It was later inferred that the alder limb involved in the incident was hung up between three Douglas-fir trees (see Figure on p. 1). The victim, at that time, was working on the other side of his strip of timber away from the hazard. At about 11:30am, another cutter working the area observed that the victim had started a warming fire and was eating lunch, and also that the hang-up was still present in the strip. The victim’s cutting partner, who was working approximately 400 to 500 feet away over a small ridge, took lunch at about 12:15pm and did not hear the victim’s chainsaw running. At 12:30pm the cutting partner, prior to going back to work, decided to check in on the victim and found him pinned underneath an alder limb. The partner had to use the victim’s saw to cut the limb off of him.

On the day of the incident it is not known whether the victim attempted to communicate with his partner but did not succeed, or if he did not recognize the magnitude of the hazard; however, he ultimately failed to contact his cutting partner to get a second opinion on how to confront the hazardous situation. Evidence from the scene suggests that the victim attempted to fell one of the three trees holding up the alder limb, putting him in position underneath the hung limb. It is probable that pressure from the alder being wedged between the three Douglas-firs placed downward tension or force on the tree the victim was cutting. This tension likely caused the Douglas-fir to fall faster than normal and allow the alder limb to fall and strike the victim before he could get in the clear (see Figure directly above).

It was observed by the OR-OSHA inspector that the victim’s cutting area was felled in an orderly fashion and that his stumps showed signs of good cutting practices. He also observed that the victim had created an adequate escape route from the last tree that he felled. However, it was the employer’s opinion after inspecting the scene after the incident, that there was an adjacent tree that could have been felled to possibly knock down the hung tree limb in a manner that would have generated less exposure to danger.

Blunt force trauma to the body.

Recommendation #1: Workers should scan for hung or snagged trees and limbs in their own and in others’ cutting strips, and communicate with each other about these hazards.

Recommendation # 2: When faced with a hazardous situation, workers should stop work and seek assistance from a supervisor, a cutting partner, or a more experienced worker.

Recommendation #3: If a snag or hung tree is identified, after seeking assistance, workers can work with their partner to use another adjacent tree to knock down the hazardous hung limb or to cripple one of the hung trees to eliminate the hazard.

Recommendation #4: Employers should ensure that workers are trained and understand how to safely respond to snagged or hung limbs and other hazardous logging conditions.

Recommendation # 5: Employers should be aware of cultural differences that may place a worker at greater risk of working under hazardous conditions, and implement extra coaching, training, or supervision to promote the value of safety over productivity or independent efficiency.

Oregon OSHA (2010). Oregon Administrative Rules, Chapter 437. Division 7 Forest Activities. Available online at: http://www.cbs.state.or.us/osha/pdf/rules/division_7/div_7.pdf

Oregon OSHA (2010). Yarding and loading handbook. Available online at: http://osha.oregon.gov/OSHAPubs/1935.pdf

Oregon FACE (2007). Fallers logging safety. Available online at: http://www.ohsu.edu/xd/research/centers-institutes/croet/outreach/or-face/publications/safetybooklets. cfm

FOR MORE INFORMATION

OR-FACE/CROET L606

Oregon Health & Science University

3181 SW Sam Jackson Park Rd

Portland OR 97239-3098

Phone 503-494-2281

Email: orface@ohsu.edu

Website: http://www.ohsu.edu/xd/research/ centers-institutes/oregon-institute-occupational-health-sciences/ oregon-fatality-assessment-control-evaluation-face/index.cfm

Oregon Fatality Assessment and Control Evaluation (OR-FACE) is a project of the Center for Research on Occupational and Environmental Toxicology (CROET) at Oregon Health & Science University (OHSU). OR-FACE is supported by a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH) (grant #2U60OH008472-06) through the Occupational Public Health Program (OPHP) of the Public Health Division of the Oregon Health Authority.

OR–FACE reports are for information, research, or occupational injury control only. Safety and health practices may have changed since the investigation was conducted and the report was completed. Persons needing regulatory compliance information should consult the appropriate regulatory agency.

The following report is the product of our Cooperative State partner and is presented here in its original unedited form from the state. The findings and conclusions in each report are those of the individual Cooperative State partner and do not necessarily reflect the views or policy of the National Institute for Occupational Safety and Health.

The Safety and Health Assessment and Research for Prevention (SHARP) Program at the Washington State Department of Labor and Industries is funded in part by the National Institute for Occupational Safety and Health (NIOSH) to run the Fatality Assessment and Control Evaluation (FACE) Program in Washington State (Cooperative Agreement No.: 5 U60 OH008336-2). The FACE Program collects information on all work-related fatalities in Washington State, investigates select incidents using a safety systems/root-cause approach, and develops reports and other outreach activities. The FACE Program is not compliance-oriented. Its goal is to reduce the number of work-related acute trauma injuries and deaths.

Oregon FACE Program OR 2011-50-1

Publication #: #OR 2011-50-1 | July 16, 2013

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More