SUMMARY

On a spring afternoon in 2005, a 52-year-old farmer and his 23-year-old hired hand were emptying manure from the pit beneath a cattle confinement shed at the farmer’s homestead. After the job was finished at about 15:30, the farmer “climbed down” the vertical manure transfer pump that was in the pit, presumably to retrieve a chain that had fallen in the pit earlier that week. While in the pit, he collapsed and fell backward.

His employee either witnessed the collapse or discovered the farmer in the pit. He ran 150 yards to the farmer’s house and told the wife to call 911 because her husband had fallen in the pit. The employee raced back to assist the farmer. He was followed by the farmer’s daughter.

The employee then entered the pit in an attempted rescue. He, too, collapsed and fell face down in four to six inches of manure that remained in the pit. The farmer’s father-in-law (who had come to the site by chance) and daughter witnessed the employee’s collapse. After completing the 911 call, the farmer’s wife rushed to the shed with a ladder to attempt rescue, but her father prevented her from entering. Within five to seven minutes of the 911 call, local firefighters and emergency responders arrived from the nearby town. Medical assistance was requested from a regional hospital 12 miles away.

An initial rescue attempt was made by an emergency responder wearing an air-purifying respirator. On his way into the pit, he had difficulty breathing and nearly passed out, but he managed to get back out of the pit. Firefighters then donned self-contained breathing apparatus (SCBA) respirators, entered the pit, and retrieved the unconscious victims. Medics took over care of the victims and transported them to the nearest hospital. From there, they were air-lifted to a tertiary-level hospital 70 miles away.

Medical evaluation of both victims revealed anoxic brain injury. Neither regained consciousness. Over the course of several days, their conditions deteriorated, and do-not-resuscitate orders were made for each individual. The farmer died four days after the incident, and his employee died ten days later.

Autopsies were performed. The cause of death for both individuals was anoxic-hypoxic encephalopathy due to inhalation of manure gases.

Factors contributing to these fatalities include:

To prevent future incidents of this nature, livestock producers should:

Additionally,

Case ID: 2005 IA 024 / 2005 IA 025 Date: 4 August 2014

This report was prepared using information from personal interviews, the county Sheriff’s Office investigative report, media reports, Medical Examiner reports, and information provided by a local implement dealership. Photographs included in this report are attributed to the Sheriff’s Office and the FACE investigator.

The employer was a family farm operation engaged in crop and beef production. The operation included the farm operator, his wife, father, and adult son; and two hired farm hands, one of whom was the second victim. They fed cattle at the site and raised corn, hay and soybeans. Manure from the cattle confinement operation was applied to their cropland as fertilizer.

A. Farmstead (2006 Google Earth Image)

The farm operation did not have a formal safety program, written programs, or safety training for employees. The farmer’s family members were not aware of the dangers of manure pit gases prior to this incident. There was no signage posted at the building to warn of these hazards.

The 52-year-old farm operator (initial victim) was an experienced farmer who had lived in the area his entire life and had farmed with his father in a family partnership from the time he graduated from high school. He was married and had resided at the family farm site for 26 years with his family. He belonged to producer commodity groups and was active in the local community.

The 23-year-old farm hand (rescuer victim) was a close friend of the farm operator’s family. He had worked part-time for the farmer during his high school years and full-time for five years following his high school graduation. The employee was considered “like family” and had lived with the farmer’s family for a period during high school. He had been a member of the local volunteer fire department for over two years. He was posthumously awarded the Carnegie Medal for Heroism the year after the fatalities.

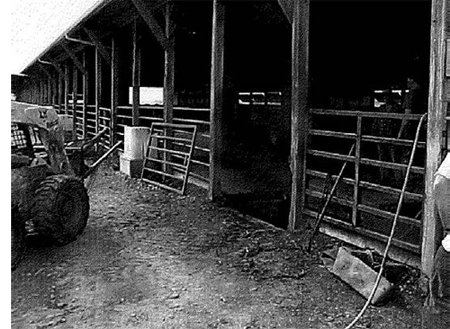

B. North side of shed with manure spreader tank

outside building Windows with white panel

covers were added after the fatalities

The incident occurred on a warm spring afternoon with little breeze. Outdoor temperature was 70 °F. Wind was from the west at 0-5 miles per hour. The family noted that the air was very still the afternoon of the fatalities. The three original windows on the north side of the building and the east and west doors were fully open, as they typically were in spring and fall during pumping. Although the building was open, lack of air movement through the building and pit likely affected the concentration of manure gases in the pit at the time of entry.

The incident occurred at a cattle shed at the northwest area of the farmstead where the farmer and his wife resided. The farm was located 0.4 miles from the nearest town with a volunteer fire department and ambulance service and 12 miles from the county seat municipality with a regional hospital and ambulance service.

The 200’ x 60’ cattle shed was constructed in 1975. It was enclosed on three sides with sliding doors on the east and west ends and three sliding-panel windows on the north wall (Exhibit B). The south side of the shed was completely open; it had steel gate partitions that opened to the adjacent lot (Exhibit C). The capacity of the building was 300 head.

A deep manure storage pit measuring 200’ x 40’ x 8’ deep ran under sections of concrete slat flooring on the south side of the building. The pit was sectioned into five compartments and had no mechanical or natural means of ventilation. The incident occurred at the east end of the pit, after the last compartment had been pumped.

At the time the building was constructed, the flooring consisted of individual concrete slats over the manure pit. Over time, the slats would periodically break and fall into the pit. In the 1980s, the farmer replaced the individual slats with 4’ x 8’ sections of slatted concrete.

The week before the incident, the farmer had shipped a load of cattle out of the shed. A log chain used to secure the livestock gate at the east end of the building had dropped into the east compartment of the pit at that time.

C. South side of shed

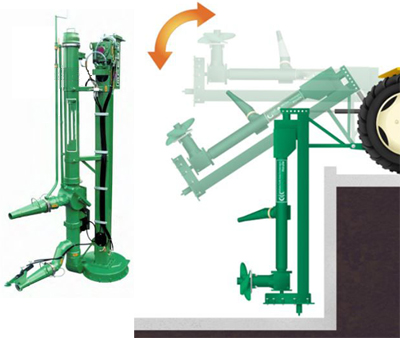

D. Example of a vertical manure transfer pump and schematic

drawing of tilting 3-point hitch attachment

The farmer had used a vertical manure transfer pump (Exhibit D) to agitate and pump contents of the pit into a manure spreader tank. The transfer pump was attached to his tractor’s 3-point hitch and was powered by the tractor’s power take-off (PTO).

In preparation to empty the pit, a section of livestock gate was removed from the south side of the building, and a skid loader was brought in to remove a 4’ x 8’ section of concrete flooring (Exhibit E). The tractor was then backed to the opening, and the vertical pump was lowered into the pit.

The pump’s agitator was usually run for up to an hour to mix the solids and liquids in the manure, prior to pumping. Agitation nozzles near the bottom of the pump could be rotated 180 degrees to control the intensity of agitation. After adequate mixing, the liquid slurry was pumped to the spreader tank (shown in Exhibit B). When the spreader tank was full, it was driven to the field and the slurry was applied to the field. Manure in the pit was agitated for another half hour prior to pumping the next load; this process was repeated until the entire pit was emptied.

Emptying the pit was typically a two or three person/two tractor job: one person operated the tractor and pump, and the other person hauled and applied the manure to the fields. The process to empty this pit usually took six hours or more. It was done twice a year, prior to planting crops in the spring and in the fall after the crops were out.

When the original single-slat flooring was in place, it had been the farmer’s usual practice to retrieve pieces of broken slats from the pit after the manure had been pumped out. The farmer’s wife and son noted that prior to replacement of the flooring, the pit had been entered on numerous occasions without incident. It had been a normal maintenance procedure to climb down on horizontal sections of the pump “like a ladder” to enter the pit and retrieve the broken slats.

The farmer began the process of agitating and pumping manure around 09:00 on the Saturday that the incident occurred. He had intended to get the manure pumped out of the pit and spread on the field that day so he could start planting corn on Monday. The east and west doors to the shed were open during the pumping, as were the three original windows along the north wall. By mid-afternoon, the final load had been pumped from the last pit compartment at the east end of the shed. The only individuals working in the immediate area were the farmer and the rescuer victim. The farmer’s son, father, and another employee were away from the farm at the time.

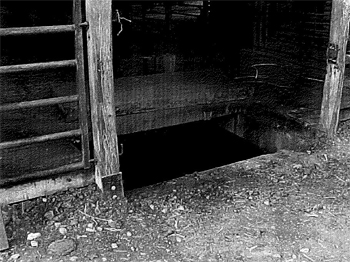

E. South side of building showing open section gate and

flooring where pump was used.

After the pit was emptied, the farmer climbed down along the horizontal supports of the pump to enter the pit (Exhibit F). He was wearing knee-high rubber wader boots and had taken a garden hoe, presumably to retrieve the log chain that had fallen into the pit several days earlier. At some point, he fell backward, landing face-up in the liquid. It is not known if the employee witnessed the farmer’s collapse or if he discovered the farmer shortly afterward.

The employee ran 150 yards to the house “screaming and yelling” to the wife to call 911, that the farmer had fallen in the pit. She called the county 911 service at 15:36, and the employee ran back to the shed; he was followed by the farmer’s daughter. The farmer’s father-in-law, who often rode over to the farm on his ATV, happened upon the scene as the employee was climbing down the pump in an attempted rescue. He saw the employee become incoherent, collapse, and fall face-down in the pit next to the pump. The father-inlaw yelled at the employee to rouse him. By this time, the farmer’s wife came running to the shed with an 8-foot ladder to attempt a rescue. Her father prevented her from entering the pit, warning her repeatedly “it’s bad, the gas is bad!” While waiting the few minutes for emergency responders to arrive, the daughter tried to reach their neighbors by phone before driving to their farms to get help.

Local law enforcement personnel, volunteer firefighters, and first responders from the nearby town’s ambulance service were dispatched to the scene at 15:36. The initial responders arrived between 15:41 and 15:47. Medical assistance was requested from the regional hospital 12 miles away. One of the responders attempted to climb into the pit wearing an air-purifying respirator and came back up gasping and unable to breathe. The victim’s son, who was a member of the volunteer fire department and had been working several miles away, raced to the scene and was prevented by other firefighters from entering the pit. Firefighters wearing SCBA respirators entered the pit and successfully retrieved the victims, both of whom were unconscious and “breathing erratically.” EMS personnel estimated the victims had been in the pit for approximately 2530 minutes. Medic services from the regional hospital took over care of the men and transported them by ambulance to the hospital. They arrived at approximately 16:30-16:35. Each was then airlifted to a tertiary-level hospital and admitted to the surgical intensive care unit.

F. Access to pit. Manure pump had been

removed following the incident.

The farmer was placed on a ventilator. Following diagnostic tests and physical examination, he was diagnosed with anoxic brain injury. His neurologic condition did not improve and a do-not-resuscitate order was made. His condition deteriorated, and he died at the hospital four days after the incident.

The employee was sustained on a ventilator and other life-support measures and developed numerous complications, including aspiration pneumonitis, sepsis, and respiratory insufficiency. A do-not-resuscitate order was made, and he was transferred to palliative care. He died at the hospital 14 days after the incident.

Factors contributing to this fatality include

Autopsies were performed on both victims.

The farmer’s cause of death was diagnosed as global anoxic-hypoxic encephalopathy due to inhalation of manure gases.

The employee’s cause of death was diagnosed as anoxic-hypoxic encephalopathy due to inhalation of manure gases. Other significant conditions noted were bronchopneumonia and aspiration pneumonia.

G. Manure gas warning signs

1. Identify manure pits as confined spaces and post warning signs at building entry and pit access points.

Confined spaces are defined by NIOSH as having “limited openings for entry and exit, unfavorable natural ventilation which could contain or produce dangerous air contaminants, and ... not intended for continuous employee occupancy.”1 Enclosed manure storage pits beneath livestock buildings and manure transfer tanks meet this definition.

Anaerobic digestion of stored manure is a natural process that produces dangerous gases (hydrogen sulfide, methane, ammonia, and carbon dioxide) which, under still conditions, remain mostly suspended in the liquid. When manure is disturbed or agitated, the gases are rapidly released through the surface into the air, resulting in concentrations that can be potentially lethal or explosive. Methane and ammonia are lighter than air and will rise to higher elevations, while carbon dioxide and hydrogen sulfide will initially settle at the lowest areas of an enclosure, such as the bottom of a pit. In a confined space, methane and carbon dioxide can displace oxygen in the air.

Hydrogen sulfide, the most toxic of these colorless gases, can cause dizziness and deaden the sense of smell, making it impossible to perceive that an environment is dangerous. At higher concentrations, it has a “knockdown” effect, causing unconsciousness in a matter of seconds. Hydrogen sulfide is lethal at concentrations above 800 parts per million (ppm); concentrations well above 1000 ppm have been measured during manure agitation (ASABE).

Because a number of unpredictable factors contribute to the likelihood of a dangerous release during agitation (such as ventilation, temperature, manure volume and age, rate of agitation, and composition of manure, among others), it is impossible to accurately determine that a pit is safe to enter without using gas monitoring devices. Pits that have previously been entered without incident can, on another occasion and without warning, become deadly environments. Family members noted the farmer had mentioned no unusual circumstances, equipment malfunctions, or atypical odors over the course of the day while the pit was pumped.

The USDA National Resources Conservation Services standard for construction of new waste storage facilities requires “[c]onfined spaces where human entry may occur shall be designed and operated in compliance with the provisions contained in ASABE EP470, Manure Storage Safety”2 (NRCS). This requirement includes proper signage to warn of gas hazards. Livestock producers and owners of existing or older facilities should also post warning signage. Signs should be posted a) at building entrances to identify manure gas hazards and b) near the pit access locations to advise of safe pit entry procedures (Exhibit G). If employees, contractors, or community emergency responders who may work on the premises have primary languages other than English, signage should be bilingual or depict the warnings graphically.

2. Train employees and inform family members, contractors, and other agricultural workers who may be at the site regarding hazards associated with manure pit environments.

Neither the victims nor the farmer’s surviving family members had prior awareness of the danger of manure pit gases or that agitating manure could create a hazardous environment that persisted after the manure had been removed. This case is not unlike other fatalities involving individuals who had entered pits to retrieve a dropped object or to perform a maintenance or repair task after other previous uneventful endeavors: based on their prior experience, they had no reason to suspect their building could be unsafe. And the fact that well-intentioned would-be rescuers do not recognize they will succomb to the same fate as the initial victim demonstrates the need for better understanding of this type of hazard.

A study group of Wisconsin agricultural engineers and safety experts concluded there exists insufficient knowledge of manure gas hazards. They recommend the use of “fast fact cards,” which focus on dangers of each of the four gases and can be used by farm personnel and others (or posted on site), in addition to press releases, formal training sessions, and development of training resources that can be used by producers, agribusinesses, county extension and conservation agencies, and rural emergency responders (Odgers et al.). One example of a “fast fact” resource tool is shown in Exhibit H.

| Hydrogen sulfide |

|

|

| Methane |

|

|

| Ammonia |

|

|

| Carbon dioxide |

|

|

Information provided for livestock workers and contractors should be bilingual. Producers should review safety procedures prior to each season’s pump-out activities. While this incident occurred in a manure storage pit, training should also address that manure gas hazards exist in transfer or spreader tanks and in low areas near open lagoons during agitation or still conditions.

3. Follow confined space entry procedures which include testing the atmosphere, working with spotters and observers, and wearing appropriate safety equipment.

Safe confined space entry cannot be performed without prior planning. If producers expect they will have occasion to enter a manure storage pit or tank, they should have a protocol in place that incorporates the following:

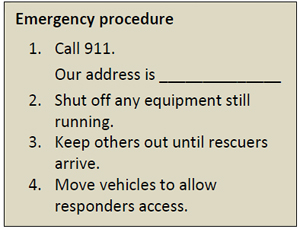

4. Develop an emergency plan that is shared with workers and family members before a potential emergency arises. Warn of the danger of attempted rescues.

I. Emergency procedure to post at farm

buildings and work sites

This incident was similar to many multiple fatalities that have occurred in manure storage pits over the past 30 years: after discovery of an initial victim that fell or collapsed due to exposure to manure gas, unprotected co-workers and/or family members rushed to pull the victim from harm and were also overcome (see other cases at the end of this report). In this type of emergency, producers and family members should plan ahead and understand that upon discovery of an incapacitated person in a pit, tank, or other confined space, they must call 911 and prevent anyone else from entering the space.

An emergency plan developed prior to an incident can save time and aid trained responders. All farm personnel and family members should be familiar with the emergency plan that includes

Information critical to emergency response should be posted at farm buildings and near confined spaces to aid persons who could be distraught or panicked (Exhibit I). Personnel, family members, and emergency responders should clearly understand that safe entry can be performed only by those trained in the use of SCBA respirators.

5. Consider purchasing or renting gas detection equipment to assess hazardous environments.

The four main gases associated with manure storage are slowly released at low levels during natural decomposition. With agitation, these gases are released rapidly, and concentrations can increase a thousand fold within minutes (ASABE). Of the four, only ammonia has warning properties to indicate a dangerous situation. The only way to determine the presence of other harmful gases is to use gas detection equipment.

Direct-reading multi-gas monitors can be purchased or rented from safety equipment suppliers. Purchase prices range from several hundred dollars to over $1000. It is important to select monitors with sensors for the specific gases of interest. With respect to manure pit gases, a multi-gas monitor (sometimes called a ‘combustible gas monitor, LEL monitor, or 4-gas monitor) should be selected with specific sensors having capability to measure:

| Oxygen (O2): | Percent oxygen by volume is reported. Adequate oxygen is required for human occupancy and for other gas sensors on the equipment to work properly. |

| Hydrogen sulfide (H2S): | Concentration is reported in ppm. |

| Methane (CH4): | Percent methane by volume is reported. Sensors alert when methane concentrations exceed the lower explosive limit (LEL). |

Unless a different gas sensor is specified, multi-gas monitors are typically configured with a fourth sensor that detects carbon monoxide (CO), reported in ppm.

Following the fatalities, the farmer’s family purchased a multi-gas monitor from a safety supply store. In the course of the FACE interview it was found that while the package and operator manual described a 4-gas monitor with various configuration options, the model they had purchased was equipped with oxygen and methane sensors only. This oversight may be due to a) the fact that methane is associated with manure pit dangers due to its explosive properties and to b) poor awareness of hydrogen sulfide and its toxic and physical properties (i.e., heavier than air). Further, the family had not been made aware of accessory equipment required to perform “bump tests” (which are conducted to assure that visual and audible alarms on the monitor work properly) or to calibrate the monitor. Having realized these problems, the family opted to rent a 4-gas monitor (equipped with all the sensors listed above) from a local safety supplier during the two weeks each year when they empty their pits. This allowed them to acquire and use equipment that was already bump-tested and in calibration. Their protocol involves placing the monitor above ground near the pit opening before, during, and after agitation, and preventing entry into the pit unless testing has confirmed the environment is safe.

The local volunteer fire department that responded at this scene did not have a gas monitor. Rural fire departments that respond to calls of emergencies in confined spaces should purchase gas monitors and use them prior to attempting entry of a space without use of SCBA. Implementing protocol for atmospheric testing prior to entry would have prevented the initial first responder’s entry and near-collapse.

6. Ventilate manure pit spaces before, during, and after agitation to dissipate toxic gases.

New animal confinement buildings with covered manure storage structures (i.e., floor over pit) are required to have built-in pit ventilation (NRCS). When pit fans are present, they should be run prior to, during, and after agitation for up to 12 hours to dilute manure gases (ASABE).

The pit under this cattle shed (and many other livestock facilities still in use) was not configured with mechanical ventilation. While the above-ground area in the shed was completely open on the south side, and all windows and doors were open on the other sides, natural ventilation was not adequate in diluting gases that had settled below the flooring. Following the incident, the family added four additional windows to the north side of the building to improve ventilation (Exhibit B).

In naturally ventilated structures, it is critical to air out the building over an extended period to allow gases to dissipate before considering entry. Monitors should then be used to determine if gas levels in the pit have dropped to safe concentrations.

7. Equipment owners should assure that manure gas warning decals are present and intact on manure transfer pumps and tanks. Equipment manufacturers should consider incorporating safety labels that warn against using the pump to access a pit.

J. Pump used at the farm in 2014

It was not known what safety decals were on the manure pump that was used at the time of the fatalities. The family had traded for a new pump at some point following the fatalities (Exhibit J). Signage on the new pump includes a decal noting “DANGER! Manure produces toxic gases that can cause a loss of consciousness, asphyxia, or death in a few seconds. Manure agitation can produce toxic gases in buildings built above the pit. Toxic gases can also emanate in buildings situated by the pit and /or connected to the pit by an evacuation line."

In follow up to this investigation, Iowa FACE visited a local implement dealership that sold new and reconditioned manure pumps. Various safety decals pertinent to manure gas hazards were present on older pumps, including one which had only a graphic depiction (Exhibit K). Not all safety decals were intact on some older pumps that had been traded and were awaiting reconditioning.3 It is important that owners maintain safety decals on equipment and replace those that are missing, torn, or corroded. New decals are typically available through dealerships that condition equipment for resale.

None of the pumps at the local dealership had signage warning against “climbing down the pump” as a means to enter the pit. This hazard was not identified or addressed in operator manuals for new pumps at the dealership, although operator manuals did prescribe following confined space entry procedures. Climbing down pumps may not be an uncommon practice to access pits, as it has also been described in a prior FACE investigation report involving a manure gas fatality (94MN057). Equipment manufacturers should consider incorporating a warning decal and instructions advising against using the pump as a ladder to access the pit.

K. Examples of manure gas warning signage on old and new equipment

American Society of Agricultural and Biological Engineers (ASABE). 1992 (R2005). Standard EP470: Manure Storage Safety. http://www.nrcs.usda.gov/Internet/FSE DOCUMENTS/nrcs142p2 019839.pdf

Centers for Disease Control and Prevention (CDC). 1993. Fatalities attributed to entering manure waste pits – Minnesota, 1992. Morbidity & Mortality Weekly Reports (MMWR) 42(17):325-329. http://www.cdc.gov/mmwr/preview/mmwrhtml/00020468.htm

NIOSH. 1990. Preventing Fatalities of Farm Workers in Manure Pits. DHHS Publication No. 90-103. http://nasdonline.org/document/1164/d000953/preventing-deaths-of-farm-workers-in-manure-pits.html

Odgers E, Ramsden J, Schuelke C, Skjolaas C, Sylla D, Thiboldeaux R, Wurzer P. 2008. Manure Gas Safety – Review of Practices and Recommendations for Wisconsin Livestock Farms. http://datcp.wi.gov/uploads/Environment/pdf/ManureGasSafetyReport.pdf

The Pig Site. 2011. Things You Need to Know about Manure Gas. http://www.thepigsite.com/articles/3565/things-youneed-to-know-about-manure-gas

USDA Natural Resources Conservation Service (NRCS). 2012. NRCS Alerts Farmers About Dangers of Manure Agitation. http://www.nrcs.usda.gov/wps/portal/nrcs/detail/pa/home/?cid=nrcs142p2_018239

USDA NRCS. Code 313: Waste Storage Facility Conservation Practice Standard. http://efotg sc.egov.usda.gov/references/public/wi/313.pdf

Virginia Cooperative Extension (VCE). 2009. Poultry and Livestock Manure Storage: Management and Safety. VCE Publication 442-308. http://pubs.ext.vt.edu/442/442-308/442-308.html

Wisconsin Department of Natural Resources (WDNR). 2010. Beneficial Management Practices for Mitigating Hazardous Air Emissions from Animal Waste in Wisconsin. http://dnr.wi.gov/topic/AirQuality/documents/bmp/FinalReport101213.pdf

Iowa FACE thanks the farmer’s wife and son and the county Sheriff’s Office for their assistance in preparing this report. We thank Eldon C. Stutsman Inc. (Hills, IA) for permission to photograph their manure pumping equipment.

This report was prepared by Stephanie Leonard and reviewed by Renée Anthony.4

1 http://www.cdc.gov/niosh/topics/confinedspace/

2 http://efotg.sc.egov.usda.gov/references/public/wi/313.pdf

3 As part of reconditioning, new safety decals are applied to equipment prior to resale

4 This publication was supported by Cooperative Agreement Number 5U60OH008460 from CDC–NIOSH, through an award to the Iowa Department of Public Health Occupational Health & Safety Surveillance Program and a sub-award to the University of Iowa FACE program. Its contents are solely the responsibility of the authors and do not necessarily represent the official views of CDCNIOSH or IDPH.

Fatality Assessment and Control Evaluation (FACE) Program

The National Institute for Occupational Safety and Health (NIOSH) an institute within the Centers for Disease Control and Prevention (CDC), is the federal agency responsible for conducting the research and making recommendations for the prevention of work-related injury and illness. In 1982, NIOSH initiated the Fatality Assessment and Control Evaluation (FACE) Program. FACE examines the circumstances the circumstances of targeted causes of traumatic occupational fatalities so that safety professionals, researchers, employers, trainers, and workers can learn from these incidents. The primary goal of these investigations is to make recommendations to prevent similar occurrences. The Iowa FACE program is one of nine state-based programs funded by NIOSH that conducts surveillance of occupational fatalities and conducts in-depth investifations fo targeted Iowa case. FACE investigation are intended to reduce or prevent occupational deaths and are completely separate from the rulemaking, enforcement and inspection activities of any other federal or stae agency. Under the FACE program, investigators interview persons with knowledge of the indicent and review available records to develop a description of the conditions and cirvumstances leading to the deaths in order to provide a context for the FACE Program's recommendations. The FACE summary of these conditions and circumstances in its reports is not inteded as a legal statement of facts. This summary, as wll as the conclusions and recommendations made by the Iowas FACE, should not be used for the purpose of litigation or the adjudication of any claim. For further information, visit the Iowa FACE Program website at http://www.public-health.uiowa.edu/face/ (1-800-513-0998), and the NIOSH FACE Program website at www.cdc.gov/niosh/face/ (1-800-232-4643).

The Iowa FACE team at the University of Iowa includes Stephanie Leonard, Program Director/Field Investigator, and T. Renee Anthony, Co-Director. Additional expertise is provided from Iowa FACE partners John Kraemer, Director, Forensic Operations at Iowa Office of the State Medical Examiner; and Stuart Schmitz, Principal Investigator and Kathy Leinenkugel, Co-Principal Investigator/Program Manager, both at the Iowa Department of Public Health.

Publication #: 2005 IA 024 / 2005 IA 025

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More