SUMMARY

In the winter of 2011, a male farmer in his 50s died when the bucket of the frontend loader he as using to clear snow from a driveway struck a 500-gallon propane cylinder, causing a fireball which engulfed the front end loader. Approximately six to eight months prior to the incident, the farm initiated a change in propane suppliers. The original propane supplier disconnected the tanks, including the incident tank, but did not pick them up from the property. The cylinder had been moved from its original location behind the home to the driveway’s turnaround area by the new propane supplier (Supplier 2) to provide easy access for Supplier 1 to haul away. The day and night prior to the incident, approximately 14 inches of snow fell. The decedent was either unaware of or forgot that the cylinder was on the driveway turnaround. It was dark when the incident occurred and the drifted snow may have hid the tank. The decedent made several passes with the loader. He struck the propane cylinder resulting in an 8-inch tall by 1-1 1/2-inch wide gash opening (Figure 1). It appears that releasing propane created a cloud which was ignited by either the heat of the front-end loader motor or a spark created by the metal on metal contact when the cylinder was struck by the bucket. The front-end loader was engulfed in flames from the resulting explosion. Emergency response was called and the decedent was transported to a nearby hospital where he died the next day from complications of the burn injuries sustained at the time of the incident.

Factors which could be involved in this incident include:

RECOMMENDATIONS

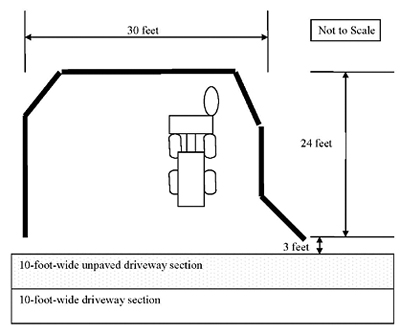

Figure 1. Position of loader and 500-gallon

propane

tank in driveway turnaround.

In the winter of 2010, a male farmer in his 50s died when the bucket of the front-end loader he was using to clear snow from a driveway struck a 500-gallon propane cylinder, causing an explosion that engulfed the front end loader. MIFACE was notified of this incident through the MIOSHA 24-hour hotline. MIFACE met with the decedent’s son at the farm office. MIFACE received permission to take pictures of the incident site (Figures 2 and 3). During the writing of this report, the police report and pictures, death certificate, and MIOSHA file were reviewed. The pictures used in Figures 1 and 4 are courtesy of the MIOSHA compliance officer.

The decedent and his wife were sole owners of the 10-year-old, 2008-incorporated dairy farm. They raised 3,000 head of dairy cows. The decedent had purchased the land which included a two-story home across the street from the farm to grow field corn.

The decedent had been in the dairy business for many more than 30 years. Additionally, the farm grew feed corn on approximately 1000 acres. The farm employed 38 individuals. The farm did not have a written farm safety plan. All employee training was performed by the decedent and other family members verbally and “on-the-job”. No training documentation was maintained.

MIOSHA General Industry Safety and Health Division issued the following Safety and Heath Recommendation to the farm at the conclusion of its investigation:

An inspection/investigation of your worksite revealed the following condition(s) which may constitute a safety or health hazard to your employee(s):

Figure 2. Driveway and turnaround leading to house. X signifies propane tank location.

Approximately six months prior to the incident, the farm changed propane suppliers for the farm operations. The original supplier (Supplier 1) unhooked the tank located in the back of the home owned by the decedent and located across the street from the farm. Supplier 2 set their 500-gallon propane tank (Figure 3) and moved Supplier 1’s 500-gallon propane tank from behind the home to the home’s driveway turnaround for easy removal by Supplier 1 (See Figure 2). After Supplier 2 moved all of Supplier 1’s propane cylinders, the decedent’s son indicated that the farm called Supplier 1 on a weekly basis during the Fall of 2010 to pick up their disconnected, not in use, propane cylinders.

On the day and night prior to the incident, fourteen inches of snow fell. The decedent and his son began working at 5:00 a.m. to clear the snow on the dairy farm property. The decedent did not clear snow on a routine basis, but due to amount of snow that fell, helped his son and other the farm’s personnel The decedent’s son had been using the Caterpillar 938 with a five-yard bucket while the decedent used another loader. The decedent and his son exchanged loaders and the decedent drove the loader across the street to clear the home’s driveway. The driveway and turnaround area was unlit.

It is unknown if the loader’s lights were fully operational and if the decedent had activated the lights. It was dark when the incident occurred and the drifted snow may have hid the tank. It appears that the decedent had made several passes with the loader while moving from west to east. As he progressed, he struck the cylinder on its end which resulted in a 8-inch tall by 1-inch gash opening. After striking the cylinder, the releasing propane created a cloud which was ignited by either the heat of the motor or a spark created by the metal on metal contact when the cylinder was struck.

Figure 3. Similar propane tank set by Supplier 2

The decedent’s son saw the fire and ran to the incident area. Another family member called for emergency response. Arriving three to four minutes later, the decedent’s son found him approximately 30 feet away from the loader lying in the snow. The sequence of events leading to the location where he was found is unknown. There were no footprints from the decedent between the loader and his resting location 30 feet away. The decedent was able to talk and explain what happened. His son placed him on a tarp and pulled him to the home’s garage to provide some relief from the heat of the fire.

Emergency response arrived approximately 20 minutes after the 911 call. The decedent was taken to nearby hospital where he died the following day.

The cause of death as listed on the death certificate was medical complications of cutaneous and inhalation injuries (burns). An autopsy was not performed.

Drawing 1. Schematic of driveway and turnaround

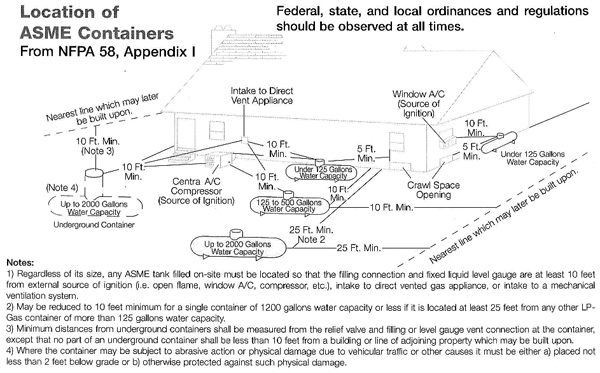

Supplier 2 moved Supplier 1’s propane tank to the driveway turnaround. There was sufficient room to place the tank out of the path of potential vehicle movement, such as a different location in the back yard, on the grass behind the turnaround, or on the grass on either side of the driveway. The Propane 101 website has a picture of the appropriate distances of propane tank placement away from a dwelling.

Appendix A contains a chart of propane tank distance rules that govern the installation of ASME propane tanks near a dwelling. The picture is courtesy of the Propane 101 website (http://www.propane101.com/index.htm).

Often on farms, the tanks are positioned to allow easy access for the propane supplier thus positioning the tanks near vehicle traffic areas. During the winter months in Michigan, blowing and drifting snow is common place, and makes it more difficult to identify the tank’s location and footprint under the snow.

The best possible protection for above ground propane tanks would be the installation of permanent protection, such as fencing, barricades (for example, a highway “Jersey” concrete barrier), or posts around the tank so vehicles could not contact the tank. The design of the perimeter barrier must allow tank access for repair and refilling.

Figure 4. Damaged propane tank and the final

location of loader bucket.

NFPA Part 58, Liquefied Petroleum Gas Code, Section 6.6.1.2, Installation Guidelines, General Requirements states: “LP Gas Containers or systems of which they are a part of shall be protected from damage from vehicles.”

MIFACE concurs with MIOSHA’s safety and health recommendation of identifying propane tank locations and expands the recommendation to include identifying the tank footprint with flags or other devices. Identification of the location and footprint could be accomplished by high visibility flags or poles, duct-tape a lath to the tank and affix orange plastic flagging, or building a temporary high visibility orange snow fence.

Propane is heavier than air. Propane tanks may contain a small amount of gas after being emptied; therefore, an “empty” tank is not an “empty” tank unless the propane dealer properly removes the remaining gas in the tank. As it was not their tank, Supplier 2 did not remove the remaining propane gas from the tank when they relocated it to the driveway turnaround. If the Supplier 1 had promptly retrieved the tank, or properly removed the remaining propane from this tank when they disconnected it from the home (even without tanking the tank from the property) this incident would not have occurred. Propane suppliers should schedule prompt pickup when service is terminated to the account.

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 909 Fee Road, 117 West Fee Hall, East Lansing, Michigan 48824-1315; http://www.oem.msu.edu. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity institution.

http://www.propane101.com/propanetankinstallation.htm

Publication #: #11MI006 | November 15, 2012

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More