SUMMARY

In 2012, a 60-year-old farmer was engulfed in soybeans while he was using a grain vacuum (“grain vac”) to pneumatically convey seed beans from a steel storage bin to a waiting grain truck. The farmer was working alone inside the bin, prior to the arrival of his employee who often worked with him to empty bins. The event occurred before daylight and was not witnessed. The driver of the tractor-trailer was in his tractor cab doing paperwork, noticed a change in the sound of the grain vacuum, and got out to see what had happened. He entered the grain bin through the side access and located the victim who was under the surface of the beans which sloped from a depth of 2 ½ feet at the entry door, to approximately 12 feet at the far side of the bin. Very shortly after this, the farmer’s employee arrived on site and found the truck driver in the bin, in a panicked state due to the situation. The employee called 911 and notified emergency responders of the situation. The employee and the truck driver tried to pull the farmer up out of the grain but were unable to free him. Local responders arrived from the town nearby and frantically worked for over 15 minutes before they were able to extricate the farmer from beneath the grain. Paramedics performed CPR and life support but the farmer was pronounced dead 15 minutes after he was extricated.

The following recommendations are made to prevent grain bin engulfment and asphyxiation:

A 60-year-old grain farmer was engulfed in soybeans and asphyxiated while using a grain vacuum to empty a steel storage bin. Iowa FACE learned of the fatality through the local press and through the family’s contact with Iowa’s Center for !gricultural Safety and Health. Iowa FACE began a preliminary investigation within two months of the fatality. Iowa FACE interviewed the victim’s family and a farm employee who worked closely with the victim for 16 years prior to the fatality. Phone interviews were conducted with the local Medical Examiner. A site visit was conducted to view the storage bin and grain vacuum. The Iowa Office of the State Medical Examiner’s preliminary report and final autopsy were used to develop this case study.

Exhibit 1: Grain bin where engulfment occurred

The 60-year-old victim was a self-employed farmer who worked in his family-owned business for over 40 years. The victim also served as a medic in the National Guard for 25 years. At the time of the incident, the family farmed over 4000 acres and employed, in addition to the family, three fulltime employees, and three or more seasonal employees, depending on the season. The family grew corn and soybeans and did not raise livestock. Those who knew him described the farmer as a gregarious, hard-working man who was very driven in his work: willing to work long hours and at a brisk pace. They noted he was not always vigilant in taking safety precautions to protect himself.

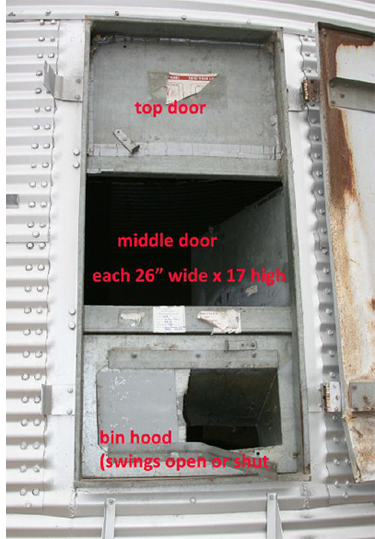

The fatality occurred in a 7600-bushel capacity grain storage bin at the farmer’s rural residence that had been filled with seed beans in October 2011 (Exhibit 1). The bin was installed at the site in 1978 about 140 yards from the roadway, and was 27 feet in diameter and 16 feet high at the eaves. The bin had one side access door 52” above the ground that was divided into three door panel openings and a fill door at the roof. The entire side door was approximately 26” x 60”, and the opening was divided into three framed openings each with clearance of about 25”x 17”. The bottom opening had a swinging “bin hood” which reduced the 25”x 17” opening to a 12”x 9.5” opening, when the bin hood was used (closed position). The bin hood could be used to hold a grain vacuum tube in position, when inserted (Exhibit 2). The bottom door with the bin hood could also be swung open allowing access to the full 25”x17” lower opening.

The night before the fatality, the farmer worked alone and emptied one or two semi loads of beans from the bin. He used an REM 3700 grain vacuum that was purchased new, two years prior to the incident (Exhibit 3).1

Exhibit 2. Side access door

The next morning, the farmer started work at 0530 (two hours before sunrise) in preparation to load out more beans. At 0600, he called the hired man who often worked with him to unload bins, and asked the hired man to pick up a piece of equipment in town on his way out to the farm.

The farm employee did the requested errand and arrived at the farm at approximately 0630. He observed the tractor-trailer on site by the grain bin but did not see anyone. The lower two panels of the side access door were open and both the tractor-trailer and the grain vac were running. He found the truck driver standing in grain in the bin, in a panicked state, and asked where the farmer was. The truck driver told the employee that the farmer was covered in beans. The farm employee immediately called 911. Local dispatch asked the employee to stay on the line but the employee got off the phone after confirming the address and tried to free the farmer. The two men located the farmer’s wrist above the grain (his body was in a sitting or sideways position, with his hand reaching up into the air). The employee stayed in the bin and maintained hold of the farmer’s wrist while he tried to shove grain away from the farmer but to no avail, because beans from the far side of the bin continued to cascade down as the employee tried to push beans from the farmer. The employee estimated the farmer held and grasped his hand for up 15 to 20 minutes before the farmer let go of his grasp.

Volunteer first responders and rescue units arrived from the nearby town at 0704. Air care was called to transport the farmer to a Level 1 trauma hospital 55 miles away. Rescuers shut off the grain vac, and unhooked the hose that was attached to the grain vac. They attached a different hose so the grain vac could be used to remove beans that covered the farmer. This was not effective, as beans continued to slide down from the sidewall to area where rescuers tried to vacuum. While rescuers worked inside the bin, the farm employee looked for any narrow pieces of plywood at the farm that could be used as a temporary dam to block the flow of beans onto the farmer, but no materials were nearby. Additional first responders arrived and a total of four to five men worked in the bin trying to shovel and vacuum beans off the farmer. Responders were able to free the farmer at 0720. Rescuers started CPR and paramedics administered advanced cardiac life support therapy. The farmer was pronounced dead at 0735 by medics and a flight nurse at the scene.

Exhibit 3. Stock photo of REM 3700 grain vac loading

grain into truck (www.rementerprises.inc.com)

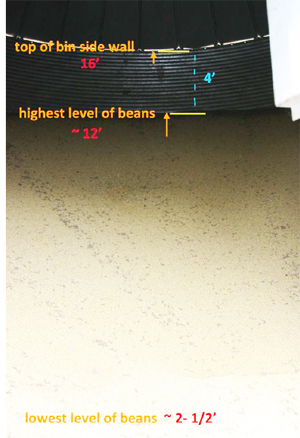

Examination of the bin contents following rescue attempts showed that the interior depth of beans was level with the bottom of the side door (2 ½ feet) and sloped up from the side door access point to a top height of about 12 feet (about 4 feet below the top of the side wall). Exhibit 4 depicts the scene inside the bin following rescue attempts, after an unknown amount of beans had been removed to free the farmer.

Exhibit 5 shows a schematic depiction of the contents of the bin as viewed from the side, based on the depth of beans measured by counting bin rings.

Initial reports claimed that the grain vacuum caught the farmer’s leg and pulled him under. Our investigation does not support this on at least two accounts: 1) the grain vacuum tube was 7” in diameter at the end, too small to pull a boot in, and 2) there was no injury to the farmer’s leg or foot which would be expected if it came into contact with the powerful grain vacuum.

A more plausible explanation is that the farmer was unable to see well inside the bin since it was not daylight and the bin was not illuminated, and that while maneuvering inside the bin (possibly attempting to move the grain vac hose), he lost his balance, slid in the inclined slope of beans, or tried to reposition the grain vacuum tube, and consequently this movement, and/or the displacement of grain by the vacuum, caused the high sidewall of beans (likely higher than 12’ high on the far wall prior to the rescue) to shift and cascade down on him. Beans in the bin had not gone out of condition (i.e., they were not sticky, crusted, or moldy) and flowed easily. A high-sloped surface of readily flowing beans presents a walking surface on which it is difficult to maintain footing and balance: walking on soybeans is like walking on small marbles. The farmer was found in a position leaning or lying toward one side, suggesting he may have slipped or slid, and then been knocked down by a volume of shifting grain.

Exhibit 4:Inside view of bin following rescue

The Iowa Office of the State Medical Examiner reported the cause of death as asphyxia due to obstruction of airway and compression of chest by grain.

Recommendation 1. Never enter a bin when working alone. Notify coworkers of a planned entry and do not enter a bin unless there are at least 2 trained partners on site.

The farmer in this incident was working alone the evening prior to this fatality, and in the morning before his hired help arrived. His spouse and family members were out of town and no others had specific knowledge of his activities, aside from the truck driver who not trained to assist the farmer or perform rescue. A policy of no-entry without two partners present would have allowed one partner to assist and monitor the farmer’s activity in the bin, and a second partner to go for help if necessary. If there was a plan in place of “no entry” unless trained partners are present, critical time may have been saved. It was not known with certainty how much time elapsed between when the farmer slipped or lost balance in grain and when the 911 call was made. Farmers or employees may be asked by seed companies, elevators, or truckers to unload bins at odd hours that are inconvenient or unfeasible for other employees or bin-entry partners to accommodate. Farmers should ensure their own and their employees’ safety by only unloading bins when a trained 3-person team is present and ready to assist with observation, entry, and rescue procedures.

Recommendation 2. Have an accident response plan in place prior to entering bins, and train employees, family members, and visiting contractors on emergency response measures.

An accident response plan describes clearly the procedures to follow in the event of a grain engulfment. Farmers and employers should develop plans and train all employees and family members on the plan so those on site can respond quickly. Anyone attending work in or around full grain bins (e.g., truckers, maintenance workers) should be made aware of the plan, and the plan should be posted or in an accessible location. The accident response plan should address locking out grain moving equipment; notification of emergency responders; providing for workers’ safety during rescue attempts- and having narrow pieces of plywood, metal, or purchased rescue tubes on hand that function as coffer dams to keep flowing grain off of a victim during a rescue attempt.

This victim’s family is actively working with the National Education Center for Agricultural Safety (NECAS) to train local responders regarding effective grain rescue techniques, and to train farmers and their employees and family members regarding hazards associated with grain bins and safe work practices.

Exhibit 5: Schematic depiction of the

level of beans in bin following rescue

Recommendation 3. Work in bins when lighting is adequate to assess potential hazards and gauge the level and slope of grain in the bin. Maintain a leveled surface of grain as grain is removed, to avoid sudden shifting and cascading of grain.

There was inadequate lighting outside and in the bin when the farmer was using the grain vacuum the morning of the incident (and possibly the evening before, as well). This may have contributed to him not fully recognizing the high sidewall of beans on the far wall of the bin across from the access door, and the potential for this volume of beans to shift suddenly. Vacuuming in a pattern that keeps the top surface of grain fairly level prevents sudden avalanche of grain, and keeps the worker above the surface where he or she can be within view of their work partners.

Recommendation 4. Follow confined space entry procedures when entering bins.

Confined space entry procedures are described by OSHA (29 CFR 1910.146) and address locking out all energized equipment (augers, elevators, conveyors); testing the atmosphere for safe oxygen levels and presence of combustible and toxic gas prior to entry; and using a team approach with observers that maintain contact with the enterer. OSHA recently issued guidelines regarding safe bin entry (http://www.osha.gov/Publications/grainstorageFACTSHEET.pdf ) and sent notification to 13,000 grain elevators warning employers not to allow workers to enter bins without proper equipment, precautions, and training (http://www.osha.gov/asst-sec/Grain-Letter-2-1 2011.html ). Employers are required to provide employees a body harness and lifeline for any entries where the worker is working at or above the surface of grain. The lifeline should be secured to prevent the employee from falling or being pulled into grain that is above waistheight, and may be attached to a winch that can assist with retrieving the worker in the event of grain entrapment. Following confined-space entry procedures ensures that those entering bins are not working alone and have observer and rescue help available, and an emergency response plan in place.

Recommendation 5. Put signage on grain bins notifying of the hazard of engulfment and asphyxiation, and warning against entry.

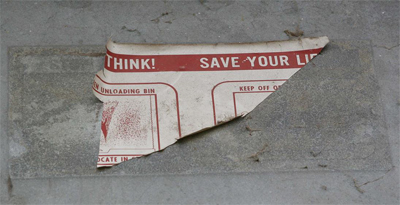

All grain bins should have clear signage stating NO ENTRY without following procedures noted above (working in teams, having a response plan, etc.). There was one remnant of a warning sign on the bin where the fatality occurred (Exhibit 6). This signage depicted a figure that represented being pulled down into grain being emptied from below on one side. The farmer in this case had emptied at least 60 bins per year during the 16 years his hired man worked for him. While the hired man was aware of dangers associated with entering bins (entrapment, air quality, flowing grain) the older farmer likely underestimated the dangers associated with bin entry based on his numerous uneventful prior experiences in the bins.

Exhibit 6. Warning sign that was on the top section of the bin's side access door.

The Iowa FACE project thanks this victim’s family and employee for assistance in developing this case report.

Purdue University Agricultural Safety and Health Program. 2010 Summary of Grain Entrapments in the United States. 2011. http://extension.entm.purdue.edu/grainlab/content/pdf/2010GrainEntrapments.pdf.

University of Arkansas Division for Agriculture. Suffocation Hazards in Grain Bins. 2010. http://www.uaex.edu/Other_Areas/publications/PDF/FSA-1010.pdf.

Occupational Safety and Health Administration. OSHA Fact Sheet Worker Entry into Grain Storage Bins. 2010. http://www.osha.gov/Publications/grainstorageFACTSHEET.pdf.

Code of Federal Regulations. 29 CFR 1910.146. Permit-required confined spaces. Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register. http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=standards&p_id=9797

Code of Federal Regulations. 29 CFR 1910.147. The control of hazardous energy (lockout/tagout). Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register. http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=980 4

1 The REM 3700 grain vac was capable of moving 10,000 bushels per hour, depending on the length and type of tubing attached to it.

Report Prepared by:

Stephanie Leonard, MS

FACE Investigator

T. Renée Anthony, PhD, CIH, CSP

FACE Investigator

Marizen Ramirez, MPH, PhD

Program Director

Fatality Assessment and Control Evaluation

FACE

Fatality Assessment and Control Evaluation (FACE) is a program of the National Institute for Occupational Safety and Health (NIOSH), which is part of the Centers for Disease Control and Prevention of the US Department of Health and Human Services. Nationally, the FACE program identifies traumatic work-related deaths, conducts in-depth studies of select cases, makes recommendations for prevention, and publishes reports and alerts. The goal is to prevent occupational fatalities across the nation.

The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE case surveillance and evaluation program and also funds state-based programs in several cooperating states. The Iowa FACE program is conducted by the Injury Prevention Research Center at the University of Iowa working in conjunction with the Iowa Department of Public Health and its Office of the State Medical Examiner.

NIOSH combines its and the state programs’ information for wide dissemination, in a variety of forms, among the industries involved. NIOSH publications are available on the web at http://www.cdc.gov/NIOSH/FACE/ and from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE also publishes its case studies, issues precautionary messages, and prepares articles for trade and professional publications. In addition to postings on the national NIOSH website, the information is posted on the Iowa FACE website (www.public-health.uiowa.edu/FACE/).

The Iowa FACE team at the University of Iowa includes Marizen Ramirez, Director; Corinne Peek-Asa, Co-Investigator; John Lundell, Co-Investigator; T. Renée Anthony, Co-Investigator; and Stephanie Leonard, Field Investigator. Additional expertise is provided from the Iowa Department of Public Health, including Rita Gergely, Principal Investigator; Kathy Leinenkugel, Surveillance Specialist; and John Kraemer, Director, Forensic Operations at Iowa Office of the State Medical Examiner.

For additional information regarding this report or the Iowa FACE Program contact:

Iowa FACE

The University of Iowa

Department of Occupational and Environmental Health

UI Research Park, 240 IREH

Iowa City, IA 52242-5000

Toll free: (800) 513-0998

Fax: (319) 335-4085

Internet: http://www.public-health.uiowa.edu/FACE

E-mail: stephanie-leonard@uiowa.edu

Publication #: 2012 IA 001 | 11 September 2012

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More