SUMMARY

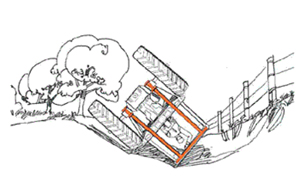

In the winter of 2010, a 71-year-old male farmer died when he was pinned by a tractor that overturned while grading a hay field edge next to a ditch. The decedent was operating a narrow-front (tricycle) tractor that was equipped with a home-made wooden push blade. The decedent was grading a field next to a ditch to lower a “dirt hill”. He had made several passes. He was traveling east when the front of his tractor began to slide down into the ditch (Figure 1). The decedent was unable to jump off the tractor as the tractor overturned and the tractor came to rest on top of him. The decedent had been observed by a neighbor who was driving past. When the neighbor returned approximately 15 minutes later, she saw the overturned tractor and called for emergency response. Emergency response arrived and declared him dead at the scene.

RECOMMENDATIONS

Although the following recommendation would not have prevented this fatality, MIFACE concluded that as a matter of prudent safe tractor operation, farmers should:

Figure 1. Incident scene.

MIFACE personnel were notified of this incident via a newspaper clipping. The decedent’s spouse agreed to participate in the research program and a MIFACE site visit was conducted in October, 2010. The police report and pictures, the medical examiner death scene investigation report and the death certificate were reviewed. The picture used in Figure 1 is courtesy of the responding police department. Pictures used in Figures 2-5 were taken by the MIFACE investigator at the time of the site visit.

The decedent was born and raised on a farm. He was a truck driver for a cement company for more than 30 years. He also had a farm during this time; he raised and sold Haflinger horses. He maintained hay fields for the horses. He purchased the incident tractor in 1971. The decedent had sustained a serious injury to his left arm, and as a result, had limited use of his left arm below his elbow. The decedent’s spouse indicated that he had difficulty controlling the tractor wheel if using his left arm only.

The decedent’s spouse indicated that she had observed in the past, the decedent conducting grading activity alongside this same ditch bank. At that time, she observed the tractor blade slide down the hill and the rear tractor wheels lift off of the ground. She discussed this observation with the decedent at the time, indicating how the activity he was performing was unsafe. The decedent did not have hired hands and did not have a farm safety and health plan. He had not attended any formal farm safety training program.

Figure 2. Incident tractor showing home-

made push blade attachment.

The decedent was operating a 1940s Allis Chalmers, tricycle tractor equipped with a homemade push blade attachment. The 5-foot long by 2 feet 8 inch high wooden blade had a 5-inch metal piece at its base. The blade was connected via a piece of channel iron on each end of the blade to 4-inch diameter metal pipes. On each pipe was a bracket that was attached to a chain, which was attached to a gear mechanism that raised and lowered the pipe and blade. The piping was welded to a metal bar attached to the back of the tractor. (See Figures 2 - 4). The decedent had attached two metal weights to the rear of the tractor (Figure 5). The two weights may have acted as counterweights to balance the additional weight the blade placed on the front of the tractor, or to balance the weight of the hoist mechanism for easier lifting of the blade. The attachment location of these weights was unknown. These weights became detached during the overturn.

The decedent had worked eight hours at another jobsite operating a bobcat/forklift to move cut logs and placing them on a conveyor. When he was ready to leave this jobsite at approximately 4:30 p.m., he called his wife and told her he was going home. When he arrived home, he did not follow his regular routine, but instead, after taking care of his dogs, took the tractor out of the barn, drove the tractor on a two-lane, paved, asphalt public roadway to the incident scene.

The decedent’s wife indicated that the decedent had indicated he wanted to grade the field’s edge so that the ridge at the edge of the field to the ditch and roadway would be less severely angled.

He had already made several passes in the field next to the ditch when a neighbor, who was driving her vehicle, saw him at approximately 7:25 p.m. She waved to him and he waved back with his right hand (thus his left hand was steering the tractor).

Evidence suggests that the decedent encountered difficulty maintaining directional control of the tractor and push blade as he made a pass along the sloped edge of the field. While he was attempting to regain control, the tractor became unstable and overturned into the ditch. The decedent was unable to jump off or free himself before the tractor came to rest on top of him. When the neighbor drove the same road back to her home 15 minutes later, she saw the overturned tractor and the decedent pinned under it. The neighbor called for emergency response. The decedent was declared dead at the scene.

Figure 3. Close view of incident

tractor

showing home-made push

blade attachment

The cause of death as stated on the death certificate was multiple crush injury. No autopsy or toxicological testing was performed.

Older tractors have limited ability to attach implements, other than what they were originally designed and intended to be used for. The decedent’s tractor did not have a 3-point hitch, so a rear-mounted blade was not possible. Using a front mounted blade on a tricycle tractor to push soil contains risk and may be a misuse of the manufacturer’s intended use of this tractor. Additionally, the use of farm built implements on agricultural tractors could contain unknown risks to the user due to engineering and other factors. The home-made push plow involved adding a great deal of weight to the front and sides of the tractor, which could have affected the stability of the tractor significantly.

Figure 4. Attachment and hoist

mechanism for raising and

lowering blade

Several safer earthmoving options include a more modern tractor with a 3-point hitch attached blade that can be adjusted for blade height or a track-type tractor with a front-mounted blade. When operating near embankments, seek to use a ROPS fitted tractor and use the seatbelt. Asking a friend, neighbor or relative to use their more modern equipment may reduce your risk for certain jobs- if your equipment is not made specifically to do the work at hand. Ensure that you know how to safely operate the equipment, how it functions, and its hazards prior to operation.

Tractor rollovers are likely to occur when the center of gravity on the tractor becomes unbalanced. The field slope, tractor speed, turning radius, rear axle torque and center of gravity are all interrelated factors that impact the stability of a tractor.

Tractor operators should determine if their older tractors can be retrofitted with an approved ROPS and seatbelt. ROPS are designed to help limit a tractor overturn to 90 degrees and to provide the operator a “zone of protection” (Figure 6). The operator stays within this zone by wearing the seat belt. The operator may not be protected by the ROPS during an overturn if the operator is not wearing a seatbelt since the operator may be totally or partially thrown off the tractor. Even inside a cab, seat belts are important to keep the operator from being thrown against the frame, through a window, or out a door. Therefore, when an older tractor is retrofitted with a ROPS, approved seatbelts must also be installed. Seat belts may or may not be included with an available ROPS package.

Figure 5. Weights attached to rear

of tractor

University of Kentucky College of Agriculture maintains a Web guide, “The Kentucky ROPS Guide” to ROPS tractor retrofits (http://warehouse.ca.uky.edu/rops/ropshome.asp). The ROPS listed in the guide are organized by tractor make and model. Another option for owners of older tractors to obtain information about ROPS retrofits is to contact their local extension office or tractor dealership.

Some tractors, like the decedent’s tractor, cannot be retrofitted with a ROPS/seatbelt according to the manufacturer or the cost of the retrofit is excessive in relation to the value of the tractor. In these cases, MIFACE recommends that the operators discontinue the use of the nonROPS/seatbelt-equipped tractor. Seat belts should not be used on tractors that do not have a ROPS.

Additionally, ROPS should not be manufactured in the farm machine shop. ROPS should be certified to meet at a minimum the standards and regulations of various agencies that ensure that the frame or enclosure is designed to provide overturn protection. http://weblogs.nal.usda.gov/infofarm/farm_safety/index.shtml. OSHA requires that ROPS are labeled/marked, therefore, tractor owners should look for a label on the frame or enclosure stating it meets rollover protection standards.

Figure 6. ROPS/Seatbelt providing

zone

of

protection

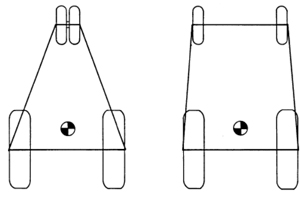

Tricycle-configured tractors, with the narrow-front wheel design are inherently less stable than tractors with a wide-wheel configuration. Tricycle tractors also have stability baselines which leave little room for error (Figure 7). The stability baseline of a tractor is made up of imaginary lines drawn between the points where the tractor tires contact the ground. Front, rear, and side stability baselines are established.

A tractor's center of gravity is the point where all parts balance one another. To avoid turnover, the center of gravity must stay within the tractor's stability baseline. Factors that may change the location of the center of gravity for the tractor or its relationship with the stability baselines are:

Figure 7. Stability baselines for

tricycle and wide-front tractors

Limiting the use of a tricycle tractor to tasks with a low risk of overturn minimizes the risk of an overturn and operator injury/death.

The decedent had limited use of his left arm due to an injury. Michigan AgrAbility helps people with disabilities employed in agriculture continue to farm and live independently. AgrAbility services are available to individuals and their families who are engaged in production agriculture. Services are provided through consultations and/or home or farm on-site visits. All consultations are kept confidential.

Michigan AgrAbility staff assists farm family members to find ways to manage with disabling conditions, such as, arthritis, chronic back pain, motion loss, hearing loss and any other conditions that limit their ability to work on the farm. The AgrAbility Project links Michigan State University Extension services with Easter Seals-Michigan, Michigan Farm Bureau and Michigan Rehab Services to provide practical education and assistance that promotes independence in agricultural production and rural living.

There are no legal requirements in Michigan for a written safety plan in agricultural industries. We recommend a written safety plan. This plan will identify the safety and health hazards for the farm, so hazard controls can be developed. A safety plan, that is communicated to all who work on the farm will help raise awareness of safety issues, promote safe work practices, and have additional benefits of increasing work efficiency, and minimizing costs (a written safety plan may reduce worker compensation premiums). A safety plan should include work rules, such as safe tractor operation and signage.

MIOSHA has many resources, including standard guidance, sample plans for safety and health issues such as respirator use, and training material handouts. Michigan Farm Bureau, with funding from the MIOSHA Consultation, Education and Training (CET) Division grant has developed a sample farm emergency preparedness safety plan as well as checklists for farm hazards. The information can be accessed at http://www.maeap.org/uploads/files/EMERGENCY_PLANNING_fillable_Form_E2575-ET_AA.pdf.

Although the following recommendation would not have prevented this fatality, MIFACE concluded that as a matter of prudent safe tractor operation, farmers should:

Although not a factor in this incident, the decedent’s tractor was operated on a public roadway and thus should have been equipped with a slow moving vehicle (SMV) emblem. A SMV emblem is a reflective orange triangle bordered with red that warns other road users that the vehicle displaying the sign is traveling slower than the normal speed of traffic. The Michigan Vehicle Code holds the tractor driver “at fault” if another vehicle rear-ends a tractor without a SMV emblem. The Michigan Vehicle Code also requires red reflective material on outboard edges of farm tractors and implements of husbandry.

Figure 8. Center SMV emblem equipped

with ASAE 276.6 recommendations

The American Society of Agricultural Engineers (ASAE) has developed new recommendations for lighting and marking equipment (ASAE S276.6, January 2005). Although the SMV emblems meeting the old ASAE standard are still available, MIFACE encourages owners of implements of husbandry operated on the roadways to purchase SMV emblems meeting the new recommendations. SMV emblems meeting the recommendations in ASAE 276.6 are in packages labeled with S276.5 or a higher number.

The new SMV emblems have fluorescent material aiding daytime visibility and reflective material aiding nighttime visibility (Figure 8). Replacing worn SMV emblems is important because the orange fluorescent center portion of the SMV emblem fades and turns color over time, changing from orange to yellow, pink or white. This portion is the most vulnerable to light and moisture degradation because fluorescent dyes decompose. Retro-reflective material as found in the outer border of the SMV emblem reflects the headlights of vehicles approaching from the rear at night.

Retro-reflective material lasts longer than fluorescent material. The retro-reflective readings on SMV emblems meeting the new ASAE standard are over ten times greater than most of the readings on SMV emblems currently in use. Figure 8 shows a comparison of older and newer SMV emblems. The SMV on the left is a new sign under the old standard, the SMV sign in the middle is the sign under the new standard, and the SMV on the right is an old sign under the old standard.

MIOSHA standards cited in this report may be found at and downloaded from the MIOSHA, Michigan Department of Licensing and Regulatory Affairs (MDLARA) website at: www.michigan.gov/mioshastandards. MIOSHA standards are available for a fee by writing to: Michigan Department of Licensing and Regulatory Affairs, MIOSHA Standards Section, P.O. Box 30643, Lansing, Michigan 48909-8143 or calling (517) 322-1845.

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 117 West Fee Hall, East Lansing, Michigan 48824-1315; http://www.oem.msu.edu. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity institution.

Publication #: 12/29/2011

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More