Objective:

To gain an awareness of the danger of flowing grain, and to learn how to prevent grain

bin entrapment.

Trainer's Note:

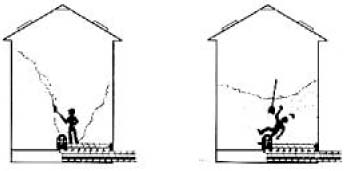

Divide the employees into three groups, read and discuss the three different ways

people become entrapped in grain and have each group come up with prevention strategies for each

one of the entrapment types (allow five minutes for this exercise). After the groups are finished, go

over the prevention strategies presented in this module. For better understanding, the graphics

provided on this sheet may be reproduced for each group.

Background

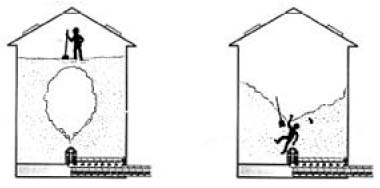

Three Types of Entrapment:

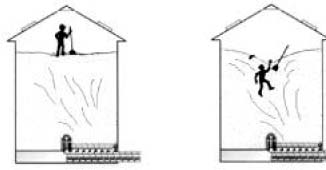

Flowing Grain

During unloading, the grain in a bin flows

downward from the top center of the bin, creating

a "funnel" effect that draws material and objects down the auger. An unloading conveyor at the bottom of the bin transports the grain outside. Depending on the size of the auger, it may take only two to three seconds to become emerged up to the knees in flowing grain, rendering the worker helpless. Flowing grain acts like quick sand and can pull a worker under and result in suffocation.

Prevention Strategies

| 1. During unloading, the grain in a bin flows downward from the top center of the bin, creating a "funnel" effect that draws material and objects down to the conveyor. | T |

F |

| 2. Flowing grain acts like quick sand and can pull a worker under and result in suffocation. | T |

F |

| 3. Always turn off and lock out power controls to the unloading conveyor or auger before entering a bin. | T |

F |

| 4. Grain bins should always be secured to prevent unauthorized entry. | T |

F |

| 5. All that is needed during grain bin entry is one observer. | T |

F |

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More