What do you need to know?

Help to Prevent Collisions

You play a vital role in helping to

prevent roadway collisions by insuring

that your equipment is as visible as

possible to other motorists. The more

visible you are, the less likely you are to

be involved in a collision. Protecting

yourself and others can make the

difference between life and death.

Protect Yourself

According to the National Safety

Council, approximately 15,000 farm

vehicles are involved in highway crashes

annually. Studies of collisions between

slow moving vehicles and motor vehicles

conclude that nearly 90 percent occur on

dry roads during daylight hours and two thirds

are rear-end collisions.

When a fatality occurs, the victim is

usually the tractor operator.

Tractors, with or without trailed

equipment, and self-propelled

implements are large enough to be

clearly visible on the highway, especially

during daylight hours. So, why are there

so many accidents involving farm

vehicles?

Many rural residents have no

experience with farming, yet they share

the roads with tractors and implements.

Lack of familiarity with farm equipment

may be responsible for their poor

judgment when gauging distances and

speeds of slow moving vehicles.

Additionally, the recognition of “something different” on the roadway may

not be apparent due to poor lighting and

marking. Tractors generally travel at less

than 20 miles per hour (mph), compared

with cars cruising at 55+ mph. A typical

driver does not instantly recognize this

difference in speed and may apply the

brakes too late to avoid a collision.

Motor vehicle drivers need to be able to

identify slow moving vehicles in time to react

safely. Protect yourself by installing the

proper lighting and marking to your

agricultural equipment. A small investment in

materials and time can help to prevent

common

roadway

collisions.

Follow the law

All self-propelled vehicles (tractors,

combines, haybines, etc.) operated on

public roadways in NY State after dark

have to comply with the lighting

specified in Table I. These lighting

requirements are in addition to the

SMV emblem requirements and do not

replace those requirements. It should

be noted that while it is recommended

to utilize the specified lighting at all

times throughout the day, NY

requirements only apply when the

agricultural equipment is used on the

public roadways from one-half hour

after sunset to one-half hour before

sunrise. At other times, no lighting

equipment is required on agricultural

equipment in NY.

How to Comply?

Lighting

Extremity lighting and reflective

material marking combined can be a

very effective guard against roadway

collisions. Used together, other

motorists can quickly and accurately

identify that a large, slow moving piece

of equipment is on the road. Without

this type of effective protection farm

equipment operators may be more at

risk of injury or even death.

The lighting requirements of both NY

state law and ASAE S279.11 can be

found in Table I. ASAE

recommendations should be followed

whenever possible since these include

some safety components that are not

included as part of the NYS law.

These additional recommendations are

standardized through a national

consensus and have been adopted by

new equipment manufacturers.

It should be noted that when rearward

facing work lamps or general service

lamps are present, that they should be

aimed downward and that they shall

not be illuminated during highway

travel. Motorists can be blinded and

confused by the illumination of

rearward facing white lights, thus

becoming a detriment to safety.

Marking

Reflective marking material is a low

cost effective tool to identifying

agricultural equipment. Properly

placed reflective material helps the

equipment stand out on the roadway.

This conspicuous feature leads the

naming of this material to be called “conspicuity material”. Ideally,

agricultural equipment on the roadway

should be conspicuous since other

motorists will notice the equipment

immediately and have sufficient time to

avoid a collision.

Reflective materials can include:

Fluorescent material which is visible in

both daytime and low-light conditions.

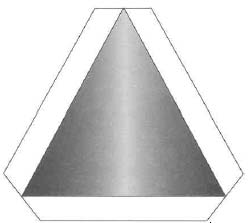

The fluorescent orange material in the

center of the new ASAE standard SMV

emblems is visible at twice the distance

as the former material. Fluorescent

color materials are comprised of

fluorescent dyes which are bright, but

unfortunately decompose and lose their

brilliance (fading) over time.

Fluorescent materials, such as the

center of SMV emblems, should be

replaced when their brilliance fades

thus reducing their effectiveness.

Retroreflective material is designed to

redirect light directly back towards its’

source. In the case of an SMV sign,

the triangular border is made of red

retroreflective tape that reflects the light

of motorists’ headlights directly back,

creating a visible warning effect. The

retroreflective border of the new SMV

signs is over 10 times brighter than the

design of the older SMV signs.

Typically the older style SMV reflective

tape was only visible from a few

hundred feet where as the new

retroreflective tape used on SMV

emblems is visible for over a mile.

Retroreflective tape can also be used

as reflectors and conspicuity material to

meet ASAE standard recommendations

at the equipment extremities. This

retroreflective material is very durable

and generally more weather resistant

than the fluorescent materials.

Silage Wagon Diagram:

Note proper location of SMV sign, Red

Retroreflective tape at rear corners, and

Orange Fluorescent tape inside next to Red

Retroreflective tape. Side and Front corners

have Yellow Retroreflective tape.

Tillage Implement Diagram:

Note proper location of SMV and Marking

tape as diagram above, although the

location on Tillage implement is directly to

frame member.

Note: Diagrams courtesy of Gempler’s

Table I: ASAE Recommendations and New York State Requirements

Lighting and Marking of Agricultural Equipment for Travel on Public Roads

| Item | ASAE Recommendations

#279.11 & S276.5 |

NEW YORK Requirements | ||

| # | Color | Mounting | ||

| Headlights | 2 | White | On either side of vehicle centerline at same height. | Same as ASAE recommendation1 |

| Tail lights | 2 | Red | Symmetrically mounted to rear between 3.3’&10’ high from 2’to 5’ on left & right of machine center | 1 Red as far to left as possible |

| Hazard Flashers | 2 or more | Amber | 3.3’to 12’ high & spaced as widely apart as practicable to be visible from front & rear. | Combined hazard, warning, and turn signal lamps. 2 amber, at least 42” high, at same level, as far apart as practicable and visible front & rear. |

| Turn Indicators | 2 | Amber & Red | Hazard flashers to also function as turn signals. | |

| SMV Emblem | 1 | Fluorescent orange for daylight & red retroreflective border for night | On rear center or rear left for maximum visibility of 600’ day or night; 2’ to 10’ above ground. | All implements of husbandry designed to operate at 25 mph or less shall display the SMV on rear of vehicle at all times on highways |

| Reflectors which may be part of tail lamp lens or conspicuity material | 2 2 |

Red on rear of

machine Yellow on front of machine |

Size to be 2” wide by 4.5” long for machines =6.7’ wide. Size to increase to 2” by 9” for wider machines. | 2 Red On rear, same level, as far apart as practicable. |

| Conspicuity material to better define size and to increase visibility. | Red retroreflectors & fluorescent markers on rear corners & =6’ apart on rear. Front: change color to yellow2 | Red retroreflective

& reorange

fluorescent Yellow retroreflective. |

Visible to rear Horizontal & in line as practicable Visible to front Reflectors to be within 16” of outside corners and fluorescent material within 25” of outer corners. |

SMV only, but additional recommended. |

|

|

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More