Over the years, electrically powered

farm equipment has become an

indispensable element of modern

farming. With the widespread use of

electricity on the farm, more emphasis

needs to be placed on using electricity

and electrical equipment safety.

Nationally, approximately 30 to 40 people

a year are electrocuted on farms. A better

understanding of the principles, uses,

and hazards associated with electricity

could have prevented many of these

deaths.

To understand the hazards associated

with electricity, it is important to know the

basic principles of electricity and how

shocks occur. Electricity's basic principles

can be explained with the terms voltage,

current (amperage), and resistance.

Voltage is the force that initiates the flow

of electric charge. The actual flow of

electric charge is called current. The rate

of flow is measured in amperes. Resistance

is based on how much a material impedes the current and

regulates the rate of flow. Electricity

usually takes the path of least resistance.

When the human body becomes part of

this path, the result is electric shock.

Two wires are needed to complete an

electrical circuit--one wire to carry the

current to an electric device, the other to

return the electricity to the power source

and finally to the ground. If the protective

insulation on any of the wires or inside a

piece of electrical equipment is defective,

the current can follow a different path to

ground. By coming in contact with a faulty

electrical object, a person may act as a

conductor to ground and experience a

shock.

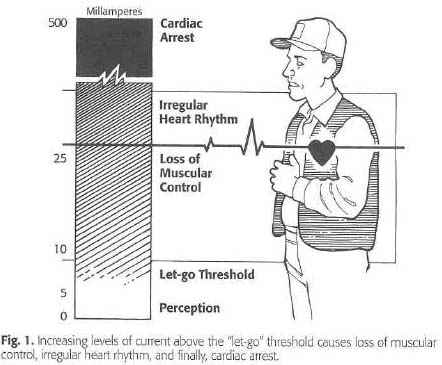

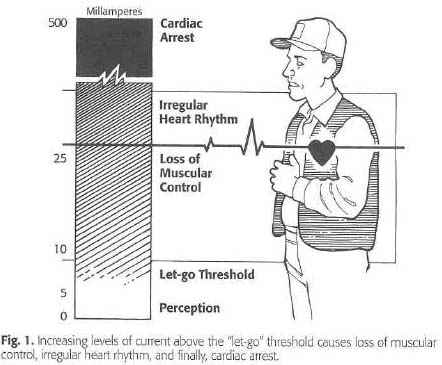

Several factors determine the effect a

shock will have on a human body: the

duration of contact, the amperage, the

path the current takes through the body,

and the electrical resistance of the body.

A person standing in water is a better

conductor than a person on dry ground.

Taken together, these factors can

produce some surprising results. For

instance, the current from a 7 1/2 watt

Christmas tree bulb (60/ 1000 of an

ampere) can kill a person if the current

passes through the heart. Figure 1 shows

the physiological effects of different

current levels.

Electricity is brought to a farm from a

power company's supply lines through

the main service entrance. Normally, all

power to the farm is metered at this point.

The main disconnect should be located

here so that all power to the farm can be

manually turned off at one point.

From the main service entrance, wires

lead to each building or area service

entrance through buried or overhead

wires. These service en- trances should

also be equipped with disconnects so

that power can be shut off to one site

without affecting other areas.

The main distribution system on a

farmstead should always be large

enough to accommodate present

demand and future expansion. Proper

installation of the electrical system is

essential for safety. Local codes should

always be followed because their main

purpose is to provide users with safe

systems. If no electric code exists for

your area, the National Electric Code

(NEC) is the minimum standard to follow.

Only qualified electricians should install

electrical systems.

Circuit Protection

Electrical systems have built-in features

to safeguard equipment and wiring from

excessive current. The most common

circuit protection is a fuse. When excess

current flows to the fuse, a portion of it

breaks, cutting power to the circuit. To

restore power, the fuse must be replaced.

A circuit breaker offers the same

protection, but is more convenient. A flip

of a switch restores power after a circuit

breaker has been tripped by an overload.

When a fuse blows or a circuit breaker

is tripped, remember:

- The circuit breaker or the fuse should

never be bypassed because this can

damage equipment or start a fire if

the circuit becomes overheated.

- Never replace a fuse with one that is

larger than that specified for the

circuit. A fuse that is too large will not

protect against an overload, which

can cause a fire.

- Do not replace fuses with pennies,

nails, bar stock, or other objects.

Many electrical fires have been

caused by such substitutions.

Grounding is a necessary safety feature

of every electrical system. It protects

against electric shock, fire, and damage

to equipment and reduces the hazards

associated with lightning. Proper

grounding for both the system and

electrical equipment is particularly

relevant for farmsteads.

System grounding starts at the main

service entrance. The neutral of the main

service is connected either to an all-metal

water pipe or to a metal rod that has

been driven into the ground. These act as

ground electrodes. If a ground rod is

employed, it must be driven deep enough

to always be In contact with moist soil (at

least 10 feet). To ensure continuity of the

ground throughout the system, each

branch service entrance should be

grounded with its neutral wire connected

to the grounded main service neutral.

Equipment grounding ensures that a

person who comes in contact with

electrical equipment does not get a shock

because of a ground fault. A ground fault

can occur when wiring connections

become loose or protective insulation is

broken or defective.

When current leaks and electrifies a

metal box or fixture, it follows a

conductive path to complete its circuit. An

equipment ground serves as a conductor

or path of low resistance.

The best way to ground power tools is

to use tools with three-wire power cords

and three-prong plugs. The third wire is

the ground and connects to the system

ground when it is plugged into a properly

grounded outlet. When using an

extension cord, be sure it has a third wire

for grounding. To confirm that

receptacles have maintained their

ground, periodically check them with a

circuit tester. Double-insulated power

tools are also available, offering

protection from ground faults by providing

a layer of insulation between the wires

and the tool's metal casing. Double insulated

power tools are not as

effectively grounded as three-wire tools

because the insulation can fail if it gets

wet.

Any metal, system, or equipment

component that may become electrified

when a fault occurs needs to be

grounded. This includes, but is not limited

to, junction boxes, motor frames, and

fuse boxes. The electrical system ground

does not ground these metallic

enclosures. A qualified electrician should

install all ground connections to make

sure the system functions properly.

Ground fault circuit interrupters (GFCI)

are also used to protect against shocks

from ground faults. A GFCI detects

current leakage at very low levels (as

little as 5 milliamps) and rapidly cuts off

the power. Three types of commonly

available GFCIs are units built into circuit

breakers, units built into receptacles, and

portable GFCIs that plug into any

receptacle.

Lockouts

Lockouts

The purpose of a lockout is to prevent

equipment from being accidentally

started and injuring people when it is

being serviced or repaired. When servicing electrically powered equipment,

a lock should always be placed on its

switch. For example, if a silo unloader

needs a repair, a lock on the control box

will prevent the machine from starting

while you are working inside the silo.

Harsh Farm Environments

Harsh Farm Environments

Many agricultural facilities have severe

environments that require special

attention when installing and maintaining

electrical systems. Threats to the system

come from a number of sources. The

vapors from

animal waste in confinement housing can

corrode electrical components. High

humidity in milking facilities can rapidly

deteriorate conventional metal electrical

boxes. Physical damage to wiring, boxes,

and light fixtures can be caused by

livestock, equipment, and people. To

protect your assets from fire or the cost of

rewiring, follow these recommendations

when installing your electrical system.

In corrosive and damp environments

- Use underground feeder (UF) electric

cable.

- Make sure all control boxes, light

fixtures, switches, and receptacles

are made of corrosion-resistant

materials.

- Install watertight covers on

receptacles and switches and over

light bulbs.

- Locate the distribution panel away

from severe environments. If a clean,

dry area, such as an office, is not

available, mount the distribution

panel outside.

- Make sure that every electrical

system component or piece of

equipment located outside is

watertight.

- Run conductors through horizontal

conduit and seal the conduit ends so

moisture cannot enter the distribution

panel. When conductors run from a

warm, moist environment to a cold

location, condensation can form and

enter the distribution panel.

- Inside farm buildings, mount wiring

outside of walls to allow continuous

inspection.

In dusty environments (such as grain or

feed handling areas):

- Place protective enclosures over all

light bulbs to protect them from dust

and lessen the fire hazard.

- Use explosion-proof switches. Fire

from an explosion can occur in areas

where fine dusts or harmful, highly

flammable vapors come in contact

with sparks from an electric switch.

In areas where physical damage to the

electrical system by livestock, equipment,

or people is likely:

- Protect circuit boxes by thought- fully

choosing their location. Placing them

around a corner or away from

animals makes the boxes far less

vulnerable to abuse.

- Run conductors in conduit to protect

them from physical damage by livestock.

- Use nonmetallic conduit in corrosive

environments.

- Place guards over light bulbs located

where they may get struck by

equipment, and use enclosures to

keep moisture and dust out.

- Use only qualified electricians to

repair damage to electrical

installations.

Standby Power

Many farm owners have standby

generators on hand to use during power

outages. When a standby generator is

installed on single phase systems, it must

be connected to the farm's wiring system

through a double-pole, double-throw

transfer switch (see fig. 6). When the

generator is in use, this switch

disconnects the farm's electric system

from the normal power supply. There are

two reasons why this is important. First, it

prevents the generator from feeding

power to power supply lines where repair

persons may be working. Second, the

normal power supply cannot feed back to

the generator and damage it when power

from the electric utility is restored.

The transfer switch must be installed

so that the generator is no more than 25

feet from the switch. Installation of the

transfer switch should always be

reviewed with the local electric supply

company.

Overhead Power Lines

Numerous electrocutions on farms have

been caused by contact with overhead

wires. Transporting equipment requiring

high clearance underneath low overhead

wires can be especially dangerous.

Fatalities have been attributed to portable

augers coming in contact with overhead

wires. These lives could have been

saved if a few minutes had been taken to

lower the equipment.

Other activities such as pruning trees

or moving irrigation pipe or metal ladders

near overhead wires can also be

hazardous. Low overhead wires are

frequently found in farm- yards and also

farm lanes between fields and roads.

Anyone working in these situations

should be made aware of the dangers

overhead wires present.

Hazards are also associated with

buried service conductors. A person

operating a trencher or excavating

equipment may get electrocuted if the

machine comes in contact with the

underground wires. Keep a detailed map

of all buried power lines to avoid such

accidents.

Electric shock can cause respiratory

paralysis, heart fibrillation, and severe

burns. If the heart stops beating and

breathing has ceased, the victim will

suffer brain damage after four to six

minutes.

It is very important to respond quickly

to an electric shock emergency. The

victim must first be separated from the

source of the shock. The best method is

to cut off the power source. Never touch

a person until he or she has been

separated from the power source, or you

also risk being electrocuted. Send for

professional medical help immediately. If

the victim is not breathing, artificial

respiration must be administered quickly.

When there is no pulse, coronary

pulmonary resuscitation (CPR) should be

started.

If you are alone and are not trained in

administering CPR, you should still

attempt to revive the victim, because this

may be the only chance for survival. Tilt

the injured person's head back, pinch the

nostrils closed with your fingers, take a

deep breath, place your mouth over his

or her mouth and blow. Move your head

away and allow the person to exhale.

Repeat. Position the heel of one hand on

the lower half of the adult victim's

sternum, place your other hand on top of

the first, and press down 1.5 to 2 inches.

Fifteen compressions to two breaths

should be repeated until professional

help arrives.

Proper installation of a farm's electrical

system is essential to electrical safety.

This includes grounding the entire system

and all electrical equipment. Protect the

electrical system and your life by using

only the appropriate fuses and circuit

breakers. Follow local electric codes or

the National Electric Code and hire a qualified electrician

when installing or modifying your

electrical system.

Finally, maintain your system by

promptly repairing any damage or

deterioration. Electrical safety is a critical

component of a productive and safe farm

business.

Power Take-Off Safety

Lightning Protection for Farms

Slow Moving Vehicle Emblems

Safer Farm Environments for Children

Safe Animal Handling

This publication is issued to further Cooperative

Extension work mandated by acts of Congress of

May 8 and June 3 0, 1914. It was produced with the

cooperation of the U.S. Department of Agriculture;

Cornell Cooperative Extension; the New York State

College of Agriculture and Life Sciences, New York

State College of Human Ecology, and New York

State College of Veterinary Medicine, at Cornell

University. Cornell Cooperative Extension provides

equal program

Designer: Dennis E Kulis

Editor: David A. Poland

Illustrations by Jim Houghton

For additional information: call 1-877-257-9777

Cornell Agricultural Health & Safety Program

Disclaimer and Reproduction Information: Information in

NASD does not represent NIOSH policy. Information included in

NASD appears by permission of the author and/or copyright holder.

More