The National Safety Council estimates that approximately 160,000 agricultural workers suffer disabling injuries each year. That is a conservative estimate — countless other accidents are never reported. Many farm injuries could be prevented or their impact reduced if farmers wore proper personal protective equipment.

This fact sheet discusses three types of personal protective equipment: protective headwear, eyewear, and footwear. Head protection designed to reduce the force of impact from falling objects can mean the difference between suffering a mild concussion or having permanent brain damage. Eye injuries, which can have a direct and dramatic effect on our quality of life, could be cut by as much as 90 percent if farmers took the time to put on a pair of goggles before using a chainsaw or repairing farm machinery. Our feet are also very delicate and susceptible to injury without the proper protection. They're made up of 26 fragile bones with very little natural padding. Safety footwear can protect our delicate feet.

Head Protection|

All

hats meeting ANSI standards are

labeled inside the shell in the following way: Manufacturer ANSI Z89.1--1997 Class ___ (A, B, or C) |

Hard Hat Maintenance

Periodically check the hat for damage, such as dents and cracks.

Never use a damaged hat. Either replace any replaceable

parts or buy a new one. Don't try to fix hats with adhesives — there

is no reliable way to ensure that dielectric or impact qualities

will be retained.

Never store a hat where it will be exposed to sunlight, such

as on the back shelf of a vehicle. Ultraviolet light can damage

and weaken nonmetallic materials such as plastic — what

most hard hats are made of today. Ultraviolet damage first

shows as dullness in the shell called chalking. Then the surface

starts to flake away and degrade. A hat exhibiting these signs

should be replaced immediately.

Signs of and Treatments for Head Injuries

The brain is one of our most fragile organs — it merely

"floats"inside the skull and is attached to it by

a network of delicate fibers. A jolt to the head can tear

blood vessels inside the brain and cause swelling, which can

reduce blood flow throughout the brain.

If a coworker suffers a head injury serious enough to cause

unconsciousness, they probably have some sort of brain injury.

Contact help immediately. If the victim is unconscious for

only a few minutes, they probably have a mild concussion.

He or she may be disoriented or confused after waking. Normal

functioning usually returns after 45 minutes or so. If the

person is still unconscious after 45 minutes, the injury is

more serious. The victim may have rapid, deep breathing or

a slow pulse — both caused by rising pressure inside the skull.

Evidence of a brain injury may not surface for several hours.

After a head injury occurs, no matter how minor the incident

might seem, the victim should be monitored for 48 hours. Look

for the following ten signs: fluid or blood coming from the

nose or ears; bruising around the eyes or ears; persistent

vomiting; large or unresponsive pupils; loss of coordination;

difficulty speaking; severe and worsening headache; double

vision; excessive drowsiness; and convulsions. These signs

can indicate anything from a cracked skull to increased pressure

inside the skull. Seek help immediately.

If a coworker suffers a head injury, try to keep him or her

still until help arrives. If the victim isn't breathing, check

for a pulse and administer CPR if necessary. Never apply pressure

to a bleeding head wound — it may push bone fragments

into the brain. Instead, lightly apply a clean, soft cloth.

Eye Protection

Eye injuries are expensive, painful, and can cause partial

or total blindness in one or both eyes. Simple precautions

can be taken to prevent them.

Most eye injuries result from flying particles. The eye's

natural protection — the surrounding bone structure,

eyelashes, tearing, and blinking — are no match for high-speed

particles and objects. Farmers should wear eye protection

when grinding feed, handling chemicals, harvesting crops,

haying, and doing shop work such as drilling or sawing. Also

wear protection when building, demolishing, or repairing structures;

repairing farm vehicles and machinery; welding and cutting

with torches; and working in dusty atmospheres.

Basic safety glasses provide protection when there is risk

of particles flying directly into the eye. They do not offer

side protection. Safety lenses worn in streetwear eyeglass

frames are not considered suitable safety glasses. Proper

safety frames have grooves into which the safety lenses fit,

preventing the lenses from popping out either forward or backward

into the eye.

Most safety glasses are available with either permanent or

detachable side shields to protect above, below, and to the

sides of the eyes. When selecting glasses with side shields,

make sure they do not interfere with peripheral vision.

Prescription safety glasses are available in a variety of

frame styles — both plastic and metal. Bifocals and tinted lenses

are also available. Variable tint lenses should be used with

caution, however, since the tinting does not always go away

instantaneously. This could be dangerous when going frequently

from the indoors to the outdoors. Tinted lenses should be

selected only when expected activities could involve bright

flashes of light (e.g. welding).

Goggles fit snugly around the eyes, providing protection from

all angles. They are good when doing chainsaw work, chipping,

riveting, and grinding. If you wear prescription glasses,

most goggles will fit around them. Goggles are usually ventilated

and treated with an antifog liquid. They are also available

in eyecup and wire mesh models. Goggles are inexpensive — about

five dollars per pair. Keep a pair next to each machine or

work area where eye protection should be worn. If working

with chemical liquids, be sure the goggles have off-set ventilation

ports.

Face shields protect workers from heat, glare, and flying

objects but they are only considered secondary protection

and must be worn with either glasses or goggles. Face shields

that attach to hard hats are available for jobs that also

require head protection.

Welding generates strong ultraviolet and infrared rays that

can permanently damage eyes and cause blindness. Welding helmets

have special filtering lenses that protect eyes from these

intense rays. They are also available in models that mount

on a hard hat. Welding goggles with various filter lens shades

protect against sparks, rays, and flying particles. Consult

a dealer to determine the filter lens shade needed for the

type of welding being done. Welding helmets and goggles are

available with either stationary or lift-front lenses. Some

helmets have ratchet-controlled headbands for proper fit and

absorbent sweatbands for comfort.

Eye Protection

Standards

ANSI also publishes a standard for eye protection: eyewear

meeting the ANSI standard is marked with the manufacturer's

name and "Z87."

Lenses undergo three tests: a high mass impact test, high

velocity impact test, and penetration test. The tests vary

slightly for the various kinds of protective eyewear. All

devices are also tested for flammability, corrosion resistance,

and cleanability.

First

Aid for Eye Injuries

The chart below summarizes what to do — and what not to do — to

properly treat an eye injury.

Protective

Eyewear Precautions and Maintenance

Protective eyewear should be cleaned regularly in warm, soapy

water. Looking through dust buildup puts unnecessary strain

on the eyes. Dry lenses with a soft tissue to avoid scratching.

Also inspect eyewear regularly for damage. Look for deep scratches

or pitting that may weaken lenses. Replace elastic goggle

headbands when they become stretched and slack. When not in

use, store eyewear in a rigid case to prevent dust buildup

and accidental damaging of delicate parts, such as frames

and nose pads.

Have eyes examined regularly to determine if you need prescription

safety glasses or a stronger prescription. Contact wearers

should always wear protective eyewear in hazardous environments.

In general, contact lenses are not recommended because they

may trap particles in the eye, posing additional risks to

the wearer; this is especially true in dusty environments.

|

Injury

|

What

not to do

|

Proper

Treatment

|

| Foreign particle in the eye. | Do not rub eyes — rubbing can scratch the eye or embed the object. | Flush eye with water until object rinses out. If this doesn't work,bandage the eye loosely and seek medical attention. |

| Object embedded in the eye. | Do not try to remove the object. | Bandage eye loosely and seek medical attention. |

| Cut near the eye. | Do not rub, press, or wash the cut — may cause further damage. | Bandage eye loosely and seek medical attention. |

| Bump or bruise near the eye. | Apply a cold compress for 15 minutes to reduce pain and swelling. Seek medical help. | |

| Welding arc burn. | Keep eyes closed and seek medical help. Note: Victim may not feel pain right away. Four to 12 hours later, eyes may be sensitive to light or may be red and swollen. |

Protective

Footwear

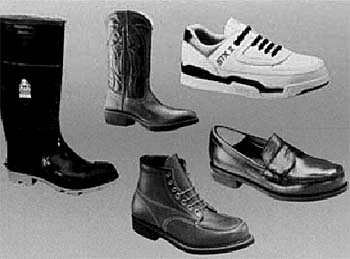

Safety shoes these days don't look like safety shoes. They're

available in a variety of popular styles, such as dress shoes,

tennis shoes, hiking boots, cowboy boots, and loafers —

both for men and women. Manufacturers realize that people

won't wear shoes that aren't comfortable and are making them

more lightweight with cushioned insoles and arch supports.

For farmers, safety pac boots, chore boots, and work boots

are available.

Farmers have received foot injuries from animals stepping

on their feet, dropping heavy objects on their feet, and stepping

on sharp objects. For the most protection, farmers should

always wear safety shoes when working.

Safety shoes usually have much more than just a steel-toe

cap for protection. Steel shanks help distribute weight more

evenly, providing support during such tasks as climbing a

ladder. Metatarsal guards either fit over the top of the shoe

or are built into the shoe to protect the top of the foot.

Steel mid soles, either built-in or slip-in, protect against

punctures and bone bruises from nails, glass, barbs, and stones.

Slip-resistant soles help prevent falls in wet barns and on

muddy ground. For winter, slip-in felt liners are available

for most styles of boots.

Examples of the variety of styles of safety shoes available.

Standards

for Safety Footwear

ANSI also establishes performance requirements and testing

methods for protective footwear. Requirements are specified

for qualities such as impact resistance, and puncture resistance.

Shoes can be marked with one of three impact ratings and one

of three compression resistance ratings. The impact ratings

are 30, 50 and 75, according to how many foot-pounds the steel

toe can withstand upon impact. The compression resistance

ratings are also 30, 50, and 75. The steel toe on a 30 shoe

will withstand 1,000 pounds of static pressure, a 50 will

withstand 1,750 pounds of pressure, and a 75 will withstand

2,500 pounds of pressure. The best protection is provided

by the highest rated shoe, but even the lowest rated shoe

offers substantially more protection than any non-rated shoe.

Steel mid soles designed to provide puncture protection must

extend from the toe to the heel of the shoe and withstand

a minimum force of 270 pounds to penetration. Mid soles are

also tested for corrosion.

Conclusion

Protective headwear and eyewear are generally inexpensive — most

hard hats and eyewear range from five to ten dollars. Though

protective footwear is more expensive, it is by nature very

durable and a worthwhile investment.

Look for the ANSI insignia on protective equipment. Compliance

with the standards is voluntary, so if a product is labeled

as meeting an ANSI standard, the manufacturer has gone the

extra mile to make sure that it performs well.

Publication #: E-39

The Pennsylvania State University is committed to the policy that all persons shall have equal access to programs, facilities, admission, and employment without regard to personal characteristics not related to ability, performance, or qualifications as determined by University policy or by state or federal authorities. It is the policy of the University to maintain an academic and work environment free of discrimination, including harassment. The Pennsylvania State University prohibits discrimination and harassment against any person because of age, ancestry color, disability or handicap, national origin, race, religious creed, sex, sexual orientation, or veteran status. Discrimination or harassment against faculty, staff, or students will not be tolerated at The Pennsylvania State University. Direct all inquiries regarding the nondiscrimination policy to the Affirmative Action Director, The Pennsylvania State University, 201 Willard Building, University Park, PA 16802-2801, Tel 814-865-4700/V, 814-863-1150/TTY.

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More