Objective:

To be able to recognize the difference between nozzles, choose the best one for the

intended job, and be able to clean nozzles properly and safely.

Trainer's Note:

Spray nozzles are important part of reducing spray drift. Choosing the correct

nozzle for the job and taking proper of care of them are an essential part of spraying safety. Have nozzles

at the training session compare the differences and practice cleaning.

Background

Nozzles regulate the spray flow, droplet size and spray pattern. Proper selection and operation of

spray nozzles are important steps in precise application. Choosing the correct nozzle is critical for

safe spray application. By using the proper nozzle for the job, less spray will drift to unintended

areas. Such as other crops, backyards, or animal pastures.

Flow regulation affects the application rate. Nozzle opening size and spray pressure are key features affecting the flow rate through nozzles. These factors can be varied by selecting a different nozzle size or adjusting the pressure.

Droplet size varies due to pressure, climatic conditions (such as: temperature, humidity, wind speed, and direction) and nozzle size. The size may be affected by the spray angle and the spray pattern shape (nozzle design). In a conventional system, droplet size can be decreased by increasing the pressure at the nozzle. Droplet size can also be decreased by increasing the spray angle of the tip.

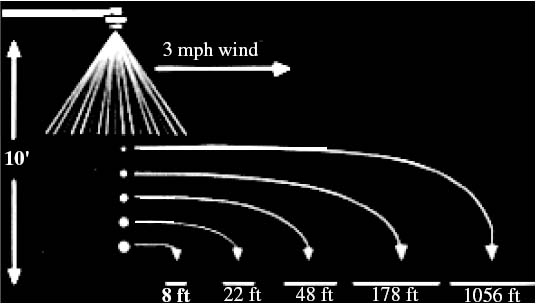

Weather has a strong influence on spray drift. Both wind direction and velocity can cause spray to drift away from its intended target. The larger the droplet, the faster it falls toward its target, and the less likely it is to drift. However, high winds can cause large droplets to drift off target. As shown in the figure, smaller droplets drift longer distances.

| Important Note: It is critical that the proper personal protective equipment (PPE) is worn when working with any type of pesticide, herbicide, or spray. Consult the label for appropriate PPE. (Refer to the modules: Reading Pesticide Labels and Pesticide Protective Equipment). |

| 1. There are three basic nozzle spray patterns, flat-spray, hollow-cone and full-cone patterns. | T |

F |

| 2. Flow regulation has nothing to do with the application rate. | T |

F |

| 3. Hollow-cone nozzles can result in high spray drift because of the many small droplets produced. | T |

F |

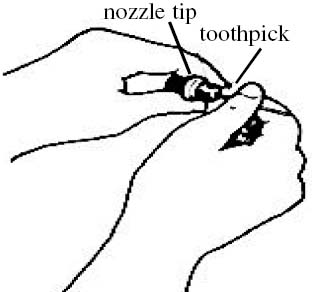

| 4. Nozzles should be cleaned with a regular detergent and a pin or knife. | T |

F |

| 5. Streaks in the nozzle's output pattern means that foreign materials are inside the nozzle. | T |

F |

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More