Editors: Kit Galvin, Jen Krenz, Pablo Palmández, Marcy Harrington

Layout & design: Stacey Holland

2012

STATE OF WASHINGTON

DEPARTMENT OF AGRICULTURE

P.O. Box 42560 · Olympia, Washington 98504-2560 · (360) 902-1800

The Washington State Department of Agriculture (WSDA) was pleased to work with growers, managers, handlers, pesticide safety educators, pest control consultants and the University of Washington’s Pacific Northwest Agricultural Safety and Health Center on this resource. We hope you find it helpful.

Washington is one of the most diverse agricultural states in the nation, featuring tree fruits, wine and table grapes, Christmas tree farms, nursery and greenhouses and many other farm products. The success of our vibrant $40 billion industry depends on a well-trained workforce and the responsible use of agricultural chemicals. The entire community shares the responsibility for protecting our workers and our rural communities’ health.

At WSDA, we take our role in ensuring the safe use of agricultural chemicals very seriously. In addition to regulating the registration, distribution and use of pesticides, our farmworker education programs are a critical piece of that work. We provide Worker Protection Standards and general pesticide safety classes, as well as more comprehensive training programs for pesticide handlers. Over 20,000 workers in Washington have benefitted from WSDA training programs, either by participating themselves or by learning from a graduate of one of our “train-the-trainer” seminars.

Agricultural workers need the right training and tools to work safely around pesticides and their residues and we want to be a resource for you.

Regards,

Dan Newhouse

Director

Safety is the “work of changing minds.

And it is not done overnight.” ~ Project participant

http://deohs.washington.edu/pnash/practical_solutions

Practical Solutions for Pesticide Safety is a collection of solutions and ideas identified on farms and reviewed and developed in a partnership with farmers, educators, and researchers in Washington state.

We hope you try these solutions in your region and on your farm, and that these ideas inspire you to develop your own safety solutions. We would greatly appreciate hearing about any solutions you develop and your experience with this guide. Please call us (PNASH (800) 330-0827) or send an email (pnash@uw.edu).

Many of the solutions in this guide may be used or adapted for a variety of crop systems. Most solutions originate from farms that use airblast sprayers for applying agricultural chemicals to tree fruit, hops, and grapes. They were selected to be practical and to protect those most at risk – pesticide handlers and their families.

Read about why farmers came up with each idea and the science behind them. You will find pictures, illustrations, and instructions to assist you in making and adopting these solutions. We’ve also included tips and resources and additional information sources are listed in the back.

We wish to thank the many people that contributed to this guide. This is as much your guide as PNASH’s. We appreciate your time, honest practical advice, and your commitment to a safe workplace and healthy community.

May this guide find you safe, happy, and prosperous!

~ Project team at the

PACIFIC NORTHWEST AGRICULTURAL SAFETY AND HEALTH (PNASH) CENTER

What is a practical solution?

A practical solution is a work practice, tool, or facility that makes work easier for pesticide handlers; it is also a safety measure. The solutions in this guide were found or developed with the help of handlers, managers, and safety educators in Washington state. We identified these solutions as practical if they were

| Useful | Safe |

| Compatible with work activities | Helps to minimize pesticide exposure |

| Convenient for handlers and management | Does not create a new health or safety problem |

| Adaptable and affordable for other workplaces |

Who is this guide for?

Farm managers and pesticide safety educators, who can learn from each other’s best practices and protect their employees and community.

What about cost?

For each solution we give an indication of the cost using the symbols below. The range considers varying costs of materials and labor, and recognizes that farms may have these items on hand.

$ - Low cost ($0–$100)

$$ - Moderate cost ($100–$500)

$$$ - Larger cost/investment (more than $500)

How were the practical solutions found?

Practical solutions were identified in several different ways

How did the agricultural community participate?

Key to the project was an Expert Working Group that met to propose, discuss, and provide direction for the project. The group was a collaboration of industry experts – managers and handlers involved in the day-to-day work on the farm – and PNASH scientists. Along with the pesticide safety educators, advisors provided their expertise in and knowledge of orchard practices and production. Twenty-five farms and 95 handlers and managers participated in the farm visits and interviews and contributed many of the solutions in this guide. Nearly 1200 people participated in evaluating and selecting the solutions through evaluation surveys, audience participation surveys at presentations, in-orchard tests, and the advisory committee for this document. (Please see our Acknowledgements.)

Where can I get more information on pesticide safety and related topics?

Specific resources are included in each section. A listing of additional information on pesticide and agricultural safety resources can be found HERE.

The US Environmental Protection Agency’s (EPA) Worker Protection Standard (WPS) covers the requirements for worker safety for agricultural use of pesticides.

Some states have additional regulations: For information on local regulations contact the appropriate state regulatory agency and see Additional Information.

Mixing and loading involves handling the pesticide concentrate. A recent study showed that on average, handlers who mixed and loaded pesticides had higher levels of pesticide exposure than those who did not (PNASH, Keifer 2011).

Spil Response Plans and Kits

Lifting Guidelines

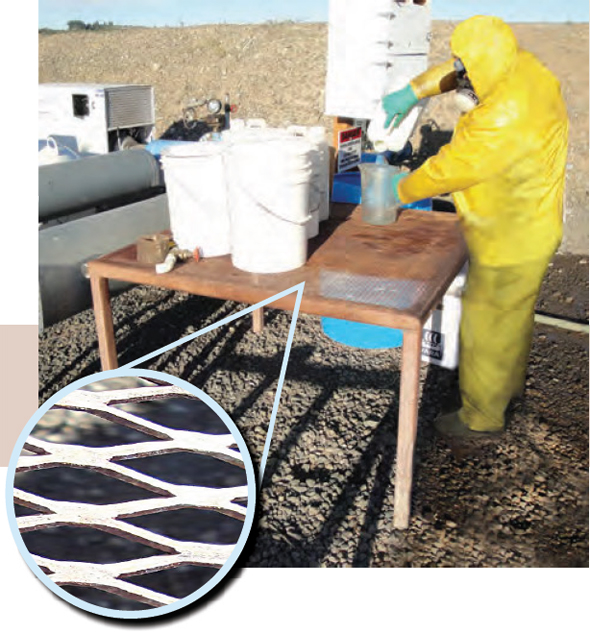

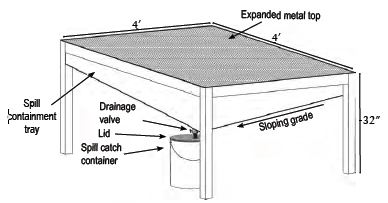

This table is constructed out of metal with an expanded metal top and cannot absorb pesticides like wooden apple bins or tables. Handlers find it easier to use because it is taller and they don’t need to bend over when measuring.

ALERT: Install a spill containment tray under the table top to catch possible spills so concentrated pesticides do not soak into the ground. Slope the tray toward a drainage plug.

IDEA:

A farm manager built this mixing table because he wanted a sturdy table that weathered well and did not absorb pesticides. He was also concerned that when his handlers used apple bins, they needed to bend over to look closely at marks on the measuring cups, resulting in an increased chance of face splashes and back strain.

“I like this table also for its height...

It can prevent back injuries during

pesticide handling.” ~ Mr. Escareño

Evaluation Finding: Nearly 75% of 199 handlers and managers surveyed said they would use the table if it were available and though it would make handling easier. PNASH, Krenz 2010

TIP:

Setup & Use

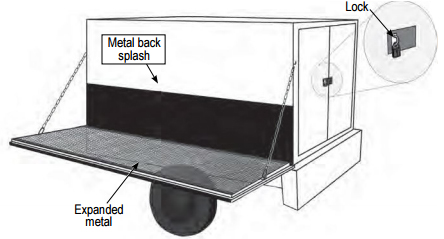

This pesticide trailer has the portable mixing table attached. The table is about waist-high.

ALERT: Secure pesticide containers before moving the trailer to prevent breaks and spills.

IDEA:

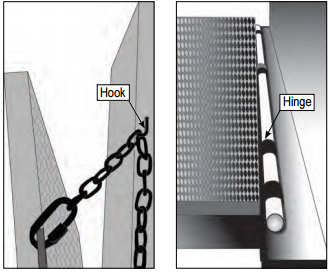

Hinges, hooks, and chains for attaching table to trailer.

TIPS:

Setup & Use

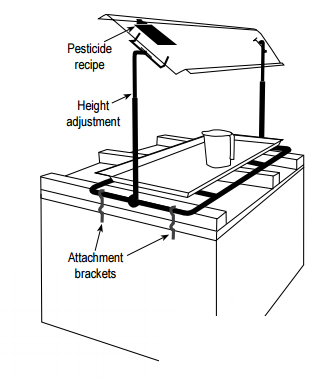

This clear rigid sheet of Plexiglas® attaches to the mixing surface and provides an additional barrier from pesticide splashes. The mixer looks through the shield while measuring pesticides underneath. The shield height is adjustable. A tray placed on the mixing surface contains spills. The splash shield can be attached to the mixing surface for the entire season, adding extra protection.

ALERT: The mixer must continue to wear eye protection and PPE as required by the label.

IDEA: The Expert Working Group designed and tested the splash shield because splashes to the eye from mixing and loading are a common pesticide-related injury. They also wanted it to be easy to make with common materials and be easy to take apart for storage.

TIP:

Setup & Use:

Research Finding:

A Washington State study on agricultural pesticide poisoning from 2003-2008 found the most common cause of pesticide poisoning for mixers/loaders was splashes in the eye. This data showed that in 73% of the cases the pesticide handler was missing eye protection. Washington State Department of Health 2010

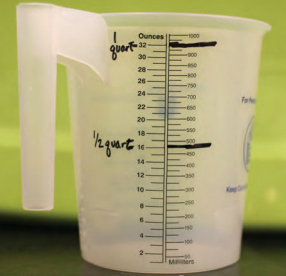

Measuring containers for pesticides and other agricultural chemicals are marked to help handlers accurately measure liquid pesticide products. Food safety regulations may require the use of liquid measuring containers that are calibrated and marked by the manufacturer. Pre-marking is a visual and educational aid to use in addition to the manufacturer’s marks.

ALERT: For accurate measure of dry products, weigh each batch separately, and do not measure additional batches by marking the containers. The size of the particles can change and the same volume may have different weights.

IDEA: A farm manager thought of this idea when he had difficulty explaining gallon measurements to a handler used to the metric system. Instructing the handler to fill to a specific mark improved communications and reduced measurement error.

“It is easier to communicate with the

pesticide

handlers about the volumes

and amounts of

pesticides to be

measured when spraying.” ~ Mr. Escareño

TIPS:

Setup & Use:

ALERT: There is an increased risk of a large chemical spill if there is a vehicle accident. Avoid busy public roads.

IDEA: A farm manager chose this solution because he determined that using the nurse tank increased application efficiency per hour by 20%.

“Previously, we had a mixing station for each 50 acres of orchard and now one

mixing station services about 335 acres. Applicators do not need to stop to mix

and load new batches; they are topped off by the nurse tank and continue

spraying. It is easier to monitor the pesticide inventory and only one employee

is mixing and loading pesticides at a centralized location.” ~ Mr. Milne

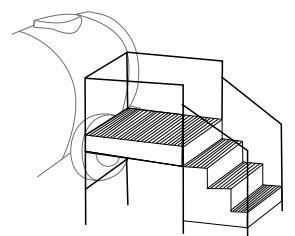

Stairs with railing for loading tank

Pesticide drift is the leading cause of overexposure for bystanders and agriculture workers in Washington state (Washington State Department of Health 2010).

TIPS:

RESOURCES:

Orchard Spraying. Cornell University

http://web.entomology.cornell.edu/landers/pestapp/apple.htmAir-blast Sprayer Calibration. WSU

http://county.wsu.edu/chelan-douglas/agriculture/treefruit/Pages/Air-Blast_Sprayer.aspxDrift Reduction and Nozzle Selection (Presentation). Pesticide Environmental Stewardship

http://www.pesticidestewardship.org/drift/Documents/Drift%20PES.ppsPesticide Drift Management. Oregon State University

http://www.ipmnet.org/Pesticide_Drift_Artwork/Spray%20Drift%20lo%20res%20print.pdfOptimize Ground Speed with Online Tool. Washington State University

http://pmtp.wsu.edu/SprayTech.phpMake your own Patternator to Check Spray Deposition. Cornell University

http://web.entomology.cornell.edu/landers/pestapp/PATTERNATOR.htm

Check orchard temperatures and wind speed with this hand-held battery-powered meter to find out if weather conditions are correct for spraying on the farm.

ALERT: Turn off tractor and sprayer when reading wind speeds as the air movement form the spray equipment will cause inaccurate readings.

IDEA: A handler uses this solution because he found weather conditions varied between close-by locations and throughout the day.

“I use it every day when spraying...

Weather factors can change anytime when

spraying in the orchard.” ~ Mr. Carbajal

TIPS:

Setup & Use:

Research Finding:

In a study looking at pesticide drift, when wind speed doubled, drift increased almost 70% downwind from the sprayer. Montana State University Extension 2008

Convex side-view mirrors are mounted on either or both sides of the tractor to help applicators view the spray pattern and nozzle function.

ALERT: Instruct applicators that the mirrors are only an aid and many operations will still require them to turn their heads to look to the side and behind them.

IDEA: A handler started using a side view mirror because his neck and back were strained from frequently turning to check for drift and clogged nozzles. His PPE hood also blocked his vision when he turned his head. He has successfully used this solution for more than 18 years.

“It reduces the chemical exposure

to the face and neck, and also reduces

neck muscle strain.” ~ Mr. McAllister

TIPS:

Optimize viewing by

Setup & Use:

Applicator viewing spray pattern in the mirror

Research Finding:

Washington State University researchers worked with 16 growers to calibrate their airblast sprayers and found that only 1 of the 16 sprayers had 100% of its nozzles working properly. Hohseisel and Granger 2009

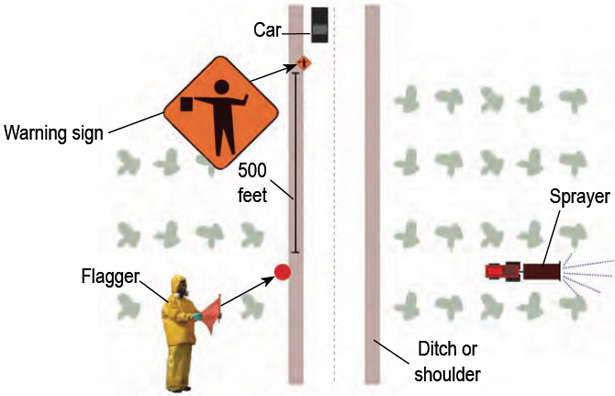

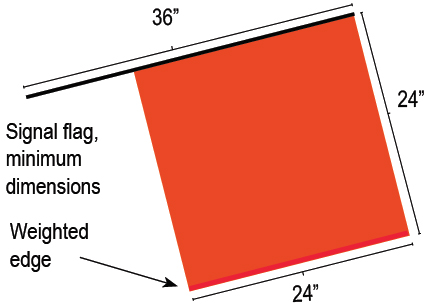

The flagger stands off to the side of the road and uses a flag to alert the applicator when a vehicle is approaching and when it has passed. The flagger and applicator are trained to use specific flag signals. The flagger is a pesticide handler, wearing the same PPE and having the same training as the applicator.

ALERT: Check each label as some prohibit flaggers.

IDEA: Before this orchard began using flaggers, the applicators would try to watch for traffic, but it was difficult for them to see approaching traffic from inside the rows.

TIPS:

“The use of a flagger by public roads is for the safety

of the workers and the public because the wind can

change any hour or minute.” ~ Mr. Madrigal

Setup & Use:

Research Finding:

Between 2003 and 2008 drift accounted for 30% of pesticide-related illnesses among agricultural workers. Washington State Department of Health 2010

Decontamination is necessary to prevent pesticide handlers, other agricultural employees, and families from being exposed. Pesticide residues are easily transferred and distributed.

TIPS:

General

Equipment Decontamination

PPE Decontamination

Personal Decontamination and Worker Facilities

RESOURCES:

General

Your Decontamination Station (DVD). Pesticide Broadcasting Network

https://pubs.wsu.edu/ItemDetail.aspx?ProductID=15349&SeriesCode=&CategoryID=&Keyword=pesticide%20broadcasting

Equipment Decontamination

Reducing and Managing Wastes from Pesticide Containment Areas. Department of Ecology

http://www.ecy.wa.gov/pubs/94186.pdf

PPE Decontamination

12-step Personal Protective Equipment Removal and Decontamination Process. Washington State Department of Agriculture

http://www.agr.wa.gov/PestFert/Pesticides/WorkerProtection.aspx#Resources (English and Spanish)

Personal Decontamination and Worker Facilities

Laundering Instructions

This system captures rinsate from application equipment decontamination. Decontamination takes place over a cement pad that drains into a shallow, steel grate-covered cement reservoir. Rinsate is transferred to a labeled application site.

ALERT: Do not mix rinsates from different applications, because they may not be allowed on the same labeled application site. Also, chemicals in different rinsates may not be compatible, and if mixed would be hazardous waste and expensive to dispose.

IDEA: A manager installed a similar system because water from equipment decontamination made the shop yard muddy and the orchard management wanted to remove pesticide residues and dispose of the rinsate according to the label.

“This is the best way to safely dispose of rinsate

from cleaning up tractors and sprayers.” ~ Mr. Oliver

TIPS:

Setup:

Use:

Use both a scrub brush and pressure washer for cleaning sprayers and tractors. Pressure washers are especially good for removing dirt and debris from hard-to-reach places on the equipment. Thorough cleaning with scrub brushes provides better overall decontamination.

ALERT: Make sure that the pressure washer is grounded to prevent possible electrocution of the operator

IDEA: The Expert Working Group wanted to know if scrubbing with soap and water or a pressure washers was more effective in cleaning application equipment. They had heard different opinions. The results (see below) show that soap and a scrub brush is more effective. Yet, pressure washing is good for hard-to-reach places.

“A mechanic in the orchard noticed that even after cleaning the sprayers with a

brush, there was still residue in hard-to-reach spots.... The pressure washer

turned out to be a successful idea.” ~ Ms.Schott

TIPS:

Setup & Use:

“I like to clean with the swinging arm system. I can clean the

equipment better, which also helps with greasing and repairing.” ~ Mr.Torres

Research Finding:

Only 10% of handlers were properly maintaining or washing spray equipment in a study of suspected pesticide-related illness cases in Washington state over 2003- 2008. Washington State Department of Health 2010

Pesticide handlers take turns pre-washing each other’s suits, boots, and gloves while they are still wearing all their PPE. They use soap, water, and a scrub brush. Afterward, each handler finishes decontaminating his own PPE.

ALERT: This practice should be voluntary because some handlers will not be comfortable pre-washing in pairs.

IDEA: A manager thought of the solution because he was concerned about pesticide residues on the PPE splashing on handlers' work clothes when they decontaminated their PPE. The handlers liked the idea and continue to use it.

“Our handlers like to do this practice and I like it too because

pre-washing PPE reduces splashes... Besides, it is easy to do.” ~ Mr. Castro

TIPS:

Setup & Use:

Inspection Finding:

50% of the Washington State Department of Labor & Industries (L&I) consultation visits based on chilinesterase inhibition cases found that decontamination was not adequate or completed in a timely manner. Washington State Department of Labor & Industries (L&I) 2007, 2008, 2009

A sink is mounted on a table and connected to a hose. Smaller items can be washed in the sink. Larger items can be scrubbed on the table. The sink is light weight and can easily be moved to other locations or storage.

ALERT: Use a metal table if possible. Wooden tables and apple bins can absorb pesticides.

IDEA: A manager set up this sink system because he found thorough cleaning of PPE is easier. The sink can be used for cleaning smaller items and soaking PPE. The raised sink also reduces back strain.

“It’s easier, comfortable, and safer to wash the respirator and

gloves in the portable sink than using a hose.” ~ Mr. Castro

Setup & Use:

This is a surface used for PPE decontamination. The cement pad is a hard, raised surface, so handlers don’t need to bend over and the water can drain away from the handler.

ALERT: Install gravel around cement pad for drainage and to prevent water build up and a muddy work area.

IDEA: A manager came up with this idea because he found thorough decontamination of PPE was difficult, especially when handlers had to bend over to scrub their PPE. The sloping cement pad provides a hard surface so the handler can scrub with pressure. The raised surface helps to prevent back strain.

TIP:

Setup & Use:

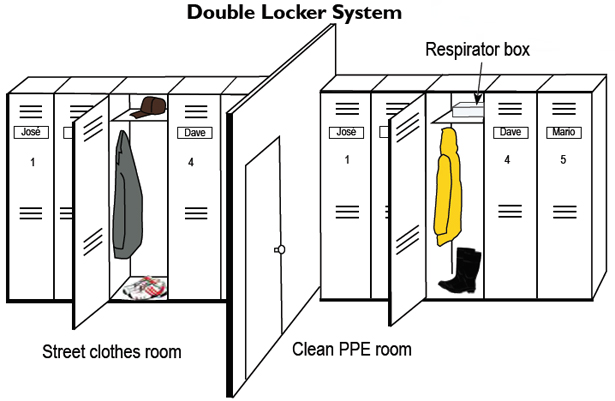

This system uses two lockers for each handler to prevent potential contamination of street clothes from PPE by storing decontaminated PPE and street clothes separately. Each type of locker is located in a separate room or area to prevent cross contamination. Separate storage of street clothes also helps to reduce unintentional exposure to family members from pesticide residues on street clothes.

ALERT: Provide individual locks or controlled access to areas where street clothes and personal items are stored.

IDEA: Double locker systems are used in many industries where workers are around hazardous chemicals to minimize worker exposure and unintentional work-to-home transfer of chemicals.

TIPS:

Setup & Use:

Research Finding:

Handlers who reporte having lockers at work had significantly less cholinesterase depression than those who did not, by an average of about 3.5 %. PNASH, Hoffman 2010

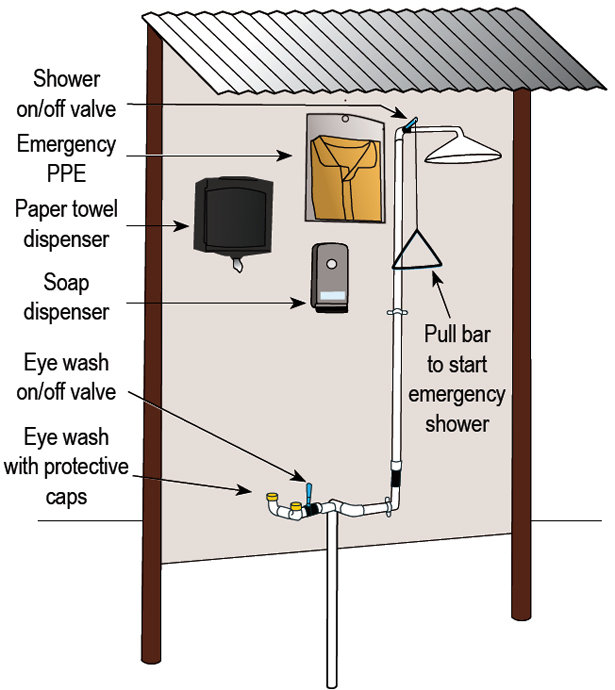

Workplace investigations show that an emergency eyewash is often missing (PNASH, Jansen 2010). Make sure there is an eyewash station in place and that each handler has immediate access to a personal emergency eyewash.

TIPS:

RESOURCES:

Safety Standards for Agriculture: Accident Prevention Program, First-aid Requirements. WA L&I

http://www.lni.wa.gov/safety/rules/chapter/307/WAC296-307.PDF#WAC_296_307_030Emergency Washing (Eyewash). WA L&I

http://www.lni.wa.gov/Safety/Topics/AtoZ/EmergencyWash/default.aspSafety Standards for Agriculture: Field Sanitation. WA L&I

http://www.lni.wa.gov/safety/rules/chapter/307/WAC296-307.PDF#WAC_296_307_095

Research Finding:

Using soap and water to wash hands can reduce pesticide residues on skin by 96%. Curwin 2003

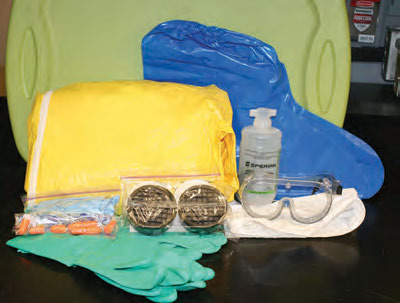

All-in-one stations have the equipment and supplies to provide first aid in case pesticide gets on the body, splashes in the eye, or soaks clothing. They provide soap, water, and towels for hand washing, emergency clothing, and spare PPE. They may be connected to a water line or be self-contained with a water supply tank. Stations may be mounted on a trailer so they can be easily moved to different locations.

ALERT: Spray drift may contaminate the station. Protect soap, paper towels, and spare PPE by putting them in a box or cabinet.

TIPS:

Setup & Use:

Investigation Finding:

One out of every 18 Worker Protection Standard (WPS) violations from 2007 to 2009 were for not providing eye-washes or other necessary supplies at mixing and loading station. PNASH, Jansen 2010

The awning protects the station from sun and rain. Place gravel around the station for good drainage.

Check with local regulatory agency to ensure emergency and sanitation station meets requirements

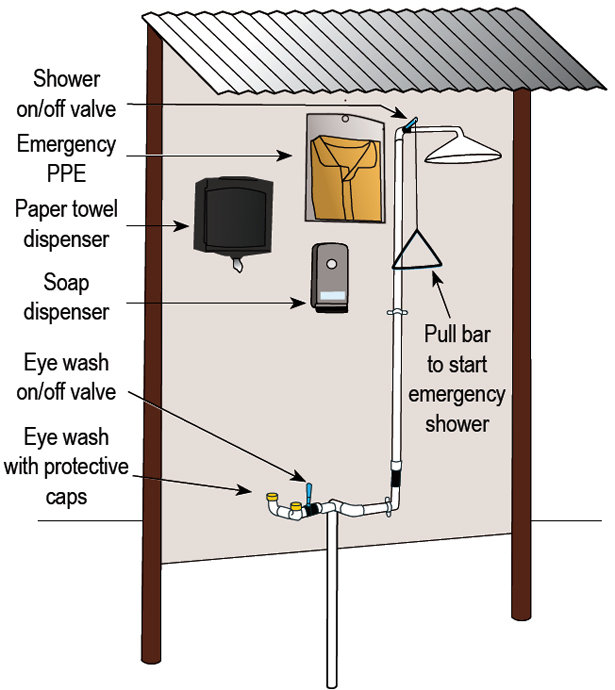

This box provides clean storage for the personal eyewash bottle. It is readily available and easy to open in an emergency.

ALERT: The eyewash water could become too hot to use if the box is located near the motor or transmission or is exposed to the sun for long periods.

IDEA: A manager thought of using an ammunition box when he saw the ammunition box on the tractor for storing tools. The PVC pipes he was using before had lids that would stick and be hard to remove in an emergency.

TIPS:

Setup & Use:

Investigation Finding:

One out of every 20 WPS violaitons from 2007 to 2009 were for not providing a pint of emergency eyewash immediately available to the handler. PNASH, Jansen 2010

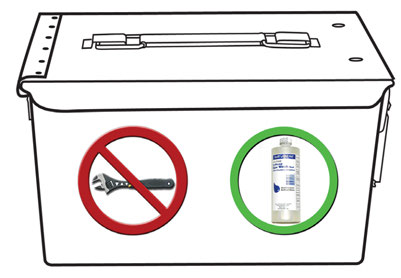

Emergency supplies and PPE are stored in a resealable plastic bag inside a tractor cab. If the applicator exits the cab, an extra set of clean PPE is available to change into before re-entering the cab. The bag can also contain emergency supplies like spare respirator cartridges for the products being applied. A similar bag can be used to store spare PPE and overalls at an emergency decontamination station.

ALERT: Take care to not contaminate the inside of the cab when changing into clean PPE.

IDEA: A manager thought of using the plastic bag because he realized that the inside of the cabs could be contaminated after the handlers got back into the cabs. Handlers need to leave the cabs if nozzles get clogged or there are mechanical problems.

TIPS:

Setup & Use:

Stock the bag with needed items including:

Train handlers to

Managing pesticide inventory is important in order to control costs and protect workers, the community, and families.

TIPS:

RESOURCES:

Pesticide Storage. Washington State Department of Agriculture

http://agr.wa.gov/PestFert/Pesticides/Storage.aspxWaste Product Disposal. Washington State Department of Agriculture

http://agr.wa.gov/PestFert/Pesticides/WastePesticide.aspxPesticide Spills – Prevention and Cleanup. Pesticide Environmental Stewardship

http://pesticidestewardship.org/spill/Pages/default.aspx

Pesticide Container Cleaning and Disposal

Pesticide Container Cleaning and Disposal. WA Department of Ecology

http://www.ecy.wa.gov/pubs/0104024.pdfPesticide Container Cleaning and Recycling (DVD). WA Department of Ecology

Hazardous Waste and Toxics Reduction Program (360) 407-6700Northwest Ag Plastics and WAPCA Plastic Container Recycling.

http://www.nwagplastics.com

Empty Pesticide Container Storage

This practice is to manage the inventory and purchase only the amount of pesticide needed for the season, return unopened containers to the supplier at the end of the season, and safely store partially used containers for the next season.

ALERT: Many pesticides do not have expiration dates on the packaging. To help with tracking, write purchase dates on removable stickers and place on containers. If dates are written directly on the pesticide containers, the distributor will not accept them if you try to return them at the end of the season.

IDEA: A manager thought of the solution .when he started to more closely watch inventory and track the pesticides used. He saw money was being wasted on pesticides that were not used. Pesticides accumulated in the storage area and became old and less effective. When a pesticide label changes and a product is phased out, it is expensive to dispose of old pesticides as hazardous waste.

“I have been using this system for many years...

we know better what we have in storage, we

don’t keep in storage pesticides not to be used

anymore, and costs decrease.” ~ Mr. Castro

TIP:

Set up:

Trays and tubs are used to separate liquid chemicals from dry chemicals and to contain spills.

ALERT: Store dry chemicals on shelves above liquid chemicals and store heavier containers on lower shelves.

TIPS:

Setup & Use:

Workplace chemicals belong at work. They can be transferred home via a worker’s car, skin, clothes, and hair. Research has found pesticide residues from work in agricultural workers’ cars, homes, and children (PNASH, Lu 2000). Other researchers’ evidence shows possible long-term effects in children exposed to pesticides when in the womb or very young.

TIPS:

RESOURCES:

Pesticide Safety Handbook, “Pesticides & the Worker” Section.

National Institute of Environmental Health Sciences

http://www.niehs.nih.gov/health/materials/pesticide_safety_handbook_english_508.pdf (English) http://www.niehs.nih.gov/health/materials/pesticide_safety_handbook_spanish_508.pdf (Spanish)

Unintentional Work-to-Home Tansfer of Pesticide Residue

Handlers have a vehicle that they use only for work, making sure their family members and other people do not drive or ride in it. Some workplaces choose to have one vehicle for transporting pesticide handlers to the work site from a central location.

ALERT: Remind handlers that others, including family members, should not ride in the dedicated vehicle.

IDEA: Two handlers were concerned about workto- home exposure so they decided to each use their own vehicle for work, and no one else rode in it. They clean the vehicles frequently to prevent build up of pesticide dust.

“I do this so I do not take pesticide residues

home and I avoid pesticide exposure outside

of work; for example, food, if I take the car

to go shopping.” ~ Mr. Montes

TIPS:

Setup & Use:

Research Finding:

When dust collected from vehicles of agricultural workers was analyzed, several organophosphate insecticides were detected. PNASH, Curl 2002

This station provides vacuums at the worksite for employees to vacuum commute vehicles. Employees vacuum and clean the inside of their vehicles on a regular basis to help prevent pesticide residues from building up inside the vehicles and inadvertently being transported from work-to-home. Employers can use the station to vacuum orchard vehicles as well.

ALERT: Extra training is needed to ensure employees are using the vacuuming station regularly.

TIPS:

Setup & Use:

Research Finding:

Levels of pesticide residues in farm workers' homes were lower if they vacuumed their commute vehicles at work before going home than those who did not. The more often they vacuumed, the lower amount of residues found. PNASH, Ballow 2006

This is a rubber or plastic tub with a lid that is kept in the trunks of agricultural workers’ personal vehicles. The agricultural worker puts his or her boots in the bin at the end of each work day. Street shoes are stored in a separate bin or clean location in the car, not in the same bin used to store work boots.

ALERT: Make sure the bin is used only for work boots and other items are not placed in it. Put warning symbols on the bin.

Using a boot bin protects family members. It contains dirt from work boots that may have pesticide residues. It helps to minimize the workto- home pesticide exposure route for families by keeping dust and dirt from work out of the vehicle and the home.

TIPS:

Setup & Use:

Evaluation Finding:

All agricultural workers who tried using a boot bin provided by PNASH reported that they liked it. PNASH, Ballow 2006

Workers wear cotton coveralls with long sleeves over their work clothes. A clean pair is worn each workday. The coveralls are cleaned by a laundry service. Alternatively, coveralls can be laundered at work.

ALERT: Wearing both work clothes and coveralls under a PPE suit can contribute to heat stress. Wear the coveralls, but not work clothes under the PPE suit to reduce the heat load.

The coveralls protect work clothes from accumulating pesticide residues and can reduce the work-to-home transfer of these residues. Wearing coveralls under the PPE reduces the chance that the work clothes or skin could be contaminated with pesticides.

TIPS:

Setup & Use:

Evaluation Finding:

One study found that an extra layer of clothin is protective. It recommends wearing coveralls over work clothes to prevent pesticide residues from accumulating on clothing. Bradman. 2009

TIPS:

Remember, PPE protects best when it is

Eliminating or reducing the source of the pesticide hazard is the best way to protect handlers. For example

RESOURCES:

PPE

Safety Standards for Agriculture: Personal Protective Equipment (PPE). WA L&I

http://www.lni.wa.gov/safety/rules/chapter/307/WAC296-307.PDF#WAC_296_307_100Safety Standards for Agriculture: Respirators. WA L&I

http://www.lni.wa.gov/safety/rules/chapter/307/WAC296-307.PDF#WAC_296_307_594Pesticides and Personal Protective Equipment. Purdue University

http://www.ppp.purdue.edu/Pubs/ppp-38.pdfPesticide Use and your Personal Protective Equipment (PPE). Oregon OSHA

http://www.cbs.state.or.us/external/osha/pdf/pubs/1018.pdfThe Air you Breathe [Respiratory Protection]. Oregon OSHA

http://www.orosha.org/pdf/pubs/3654.pdf

IPM

Integrated Pest Management. Washington State University Extension

http://ipm.wsu.eduUC IPM Online. University of California-Davis

http://www.ipm.ucdavis.edu/index.htmlApple IPM Transition Project. Washington State University

http://pmtp.wsu.eduField Guide for Integrated Pest Management in Hops. OSU, U of Idaho, WSU, USDA ARS

http://ipm.wsu.edu/field/pdf/HopHandbook2009.pdfVinewise. Washington Association of Wine Grape Growers

http://www.vinewise.org

I noticed an applicator on a neighbor’s farm wearing a Nor’wester

type hat under his hood. He wore the hat backwards, which created

a large bill under the hood. I adopted the idea and found it was a

great addition to my spray gear. ~ Ms. Schott

Research Findings:

Please refer to your state’s departments of agriculture, labor, or occupational safety and health.

Environmental Protection Agency - Protecting Workers

http://www.epa.gov/pesticides/health/protecting-workers.htmlEXTOXNET - Pesticide Toxicology and Environmental Chemistry Infobase

http://extoxnet.orst.edu/faqs/index.htmNational Pesticide Information Center (NPIC),

Information and consultation (Spanish and English) (800) 858-7378

http://www.npic.orst.edu/Occupational Safety and Health Administration (OSHA)

http://www.osha.gov/

Washington State Department of Agriculture - Pesticides

http://www.agr.wa.gov/Portals/PFWashington State Department of Health Pesticide Program

http://www.doh.wa.gov/AboutUs/ProgramsandServices/Environmental...Washington State University Pesticide Safety Education Program - Certification and Training

http://pep.wsu.edu/Washington State Department of Labor and Industries - Agriculture

http://www.lni.wa.gov/Safety/Topics/AtoZ/topic.asp?KWID=353Washington Poison Center, (800) 222-1222; (800) 572-0638

http://www.wapc.org/Washington State Department of Labor and Industries - Cholinesterase Monitoring

http://www.lni.wa.gov/Safety/Topics/AtoZ/Cholinesterase/default.asp

NOAA’s Heat Watch

http://www.nws.noaa.gov/om/heat/ww.shtmlOSHA’s Campaign to Prevent Heat Illness in Outdoor Workers

http://www.osha.gov/SLTC/heatillness/index.htmlPacific Northwest Agricultural Safety and Health Center

http://depts.washington.edu/pnash/heat_illness.phpWashington State Department of Labor and Industries

http://www.lni.wa.gov/Safety/Topics/AtoZ/HeatStress/

Agricultural Health Study

http://aghealth.nci.nih.govMigrant Clinician’s Network

http://www.migrantclinician.org/issues/occupational-health.htmlThe National Agricultural Safety Database (NASD) is an online collection of information about health, safety and injury prevention in agriculture

http://www.nasdonline.org/National Pesticide Applicator Certification Core Manual

http://nasda.org/9381/Foundation/11379/11383/30485.aspxPacific Northwest Agricultural Safety and Health Center - Pesticides Scientific Evidence & Educational Tools

http://www.depts.washington.edu/pnash/pesticides_healthPesticide Action Network offers a database about various pesticides and effects

http://www.pesticideinfo.org/Index.htmlWashington State Department of Labor and Industries has courses and videos available free of charge

http://www.lni.wa.gov/Safety/TrainTools/Videos/The Washington Environmental Stewardship website (PES) provides recommendations for proper pesticide handling

http://www.pesticidestewardship.org/Pages/default.aspx

National Pesticides Information Center (800) 858-7378

http://npic.orst.edu

National Poison Control Center Hotline (800) 222-1222

Bradman A, Salvatore A, Boeniger M, Castorina R, Snyder J, Barr D, Jewell N, Kavanagh-Baird G, Striley C, Eskenazi B. Community-Based Intervention to Reduce Pesticide Exposure to Farmworkers and Potential Take-Home Exposure to their Families. Journal of Exposure Science and Environmental Epidemiology. 2009;19:79-89.

Curwin BD, Hein MJ, Sanderson WT, Nishioka M, Buhler W. Acephate Exposure and Decontamination on Tobacco Harvesters’ Hands. Journal of Exposure Analysis and Environmental Epidemiology. 2003;13:203-210.

Hoheisel G and Granger K. Lessons Learned and Initial Evaluation of a Pessl Spray Calibration Machine on Ground Sprayers. Poster by Washington State University Extension. 2009.

Montana State University Extension. Avoiding Pesticide Drift. 2008. http://www.pesticides.montana.edu/Reference/Drift.htm accessed on 14 September 2011.

PNASH

Ballow C. An Intervention Aiding in the Reduction of Oganophosphorus Pesticides from Take-home Pathways. MS Thesis, University of Washington Department of Environmental and Occupational Health Sciences. 2006 June.

Curl CL, Fenske RA, Kissel JC, Shirai JH, Moate TF, Griffith W, Coronado G, Thompson B. Evaluation of Takehome Organophosphorus Pesticide Exposure among Agricultural Workers and their Children. Environmental Health Perspectives. 2002 Dec;110(12):A787-92.

Jansen C, Keifer M, Murphy-Robinson H, University of Washington, Washington Departments of Agriculture, Health and Labor and Industries. Using Data to Identify and Address Causes of Pesticide Over-exposure in Washington State Agricultural Employees. Poster Presentation at Western Migrant Stream Forum, Seattle, WA. 2010 Feb.

Keifer M, Krenz J, Smith T, Hoffman J, Cunningham R, Simpson C, Fenske R. Determinants of Serum Cholinesterase Inhibition among Agricultural Pesticide Handlers in Washington State, 2006-2011. Manuscript in preparation 2011.

Krenz J. Minimizing Pesticide Handler Pesticide Exposure: Practical Solutions Fresh from the Orchard. MPH Thesis, University of Washington Department of Environmental and Occupational Health Sciences. 2010 June.

Lu C, Fenske RA, Simcox NJ, Kalman D. Pesticide Exposure of Children in an Agricultural Community: Evidence of Household Proximity to Farmland and Take Home Exposure Pathways. Environmental Research. 2000 Nov;84(3):290-302.

Washington State Department of Labor and Industries. Cholinesterase Monitoring of Pesticide Handlers in Agriculture: 2007 Report. 2007 Dec 20.

Washington State Department of Labor and Industries. Cholinesterase Monitoring of Pesticide Handlers in Agriculture: 2008 Report. 2008 Dec 20.

Washington State Department of Labor and Industries. Cholinesterase Monitoring of Pesticide Handlers in Agriculture: 2009 Report. 2009 Nov 20.

Washington State Department of Health. Contributing Factors to Pesticide Related Illness among Agricultural Workers in Washington State, 2003-2008. DOH 333-172 Sept 2010.

Thank you to the 25 farms and 95 growers, managers, handlers, and safety educators who shared their innovative ideas.

These solutions are a testament to the impressive level of care and dedication in our farming communities.

Expert Working Group (EWG)

A dedicated team of 17 pesticide handlers, farm managers, owners, and pesticide safety educators who provided practical solutions and advised on farm practices and needs. This and additional hands-on development and field-testing at several of your farms make the solutions in this guide truly “Farm Tested.” The EWG was at the heart of this project, keeping us focused on practical and realistic solutions for use in agricultural workplaces throughout the five year project.

Regional Advisory Committee for the Guide

A group of 10 professionals from industry, government agencies, non-governmental organizations, commercial suppliers, growers, and agricultural extension reviewed the developing guide on final safety, regulatory and communication issues. Their expertise and suggestions for improvement were essential to the guide.

Conference Audiences

Thank you to the over 1000 managers, pesticide handlers and agricultural safety and health professionals who evaluated solutions using multiple choice “clickers” during industry presentations. The feedback on interest, practically, and uniqueness of proposed solutions guided the project teams and advisors.

Evaluation Survey Participants

We are grateful to the 29 managers and pesticide safety educators who conducted a detailed evaluation of potential solutions. Their time and honesty was indispensable in making decisions on what solutions to modify and include in the guide.

PNASH Project Team

The idea for the Practical Solutions for Pesticide Safety guide arose from what we observed at farms during previous research projects. We knew of farms that developed their own pesticide safety measures and had new ways of implementing old ones. We were inspired to identify and evaluate these “farm grown” solutions and share them with the agricultural community. Working with the support and participation of the agricultural community was essential to the project’s success and extremely gratifying for PNASH faculty, staff, and students. Thank you.

A special thank you to the Washington State Department of Agriculture’s Farmworker Education Program and Washington State University Extension for your support throughout the project.

School of Public Health, University of Washington National Institute of Occupational Safety and Health Award #2 U50 OH07544

Practical Solutions for Pesticide Safety

© 2012 University of Washington First edition,

first printing

Permission is granted to reprint and distribute, provided that this copyright notice and permission statement is retained. Unless otherwise noted, photos and illustrations are the property of the PNASH Center.

Pacific Northwest Agricultural Safety and Health Center

Dept. of Environmental and Occupational Health Sciences

University of Washington, Box 357234

Seattle, WA 98195-7234 USA

(206) 616-1958, (800) 330-0827

pnash@uw.edu

http://depts.washington.edu/pnash/

The Practical Solutions for Pesticide Safety guide was created by the University of Washington (UW) Pacific Northwest Agricultural Safety and Health Center, under the lead of Richard Fenske, PhD, MPH, Principal Investigator. This project was funded through a cooperative agreement with the National Institute of Occupational Safety and Health (NIOSH/CDC) Award #2 U50 OH07544.

Disclaimers: The contents of this publication are solely the responsibility of the authors and do not necessarily represent the official views of NIOSH/CDC, UW, WSDA, or WSU. Mention of any company of product does not constitute endorsement.

Publication #: U50 OH07544

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More