The tailgate training method, sometimes called a toolbox safety talk, is a training method in which on-the-job training sessions occur frequently and are conducted in 10-15 minute sessions.

Tailgate trainings are commonly used in the construction industry because of the dangerous nature of this occupation, but have also been used successfully in the agriculture sector.

The goal of this training manual is to provide bison handlers with basic safety and health information that can be reviewed immediately prior to working with bison. These trainings should become part of a worker’s basic routine. The overall aim is to decrease the number of injuries to workers that occur while rounding up and handling bison.

Each section in this training manual contains four common elements: a topic, a goal, a background section, and a review section. At the end of the manual are attendance sheets to be used to document who attended each training.

The topic states what the section is about.

The goal states what is expected to be learned.

The background section states the information that is to be taught. The background section may be in various forms, such as paragraphs or bullet points, and may also contain pictures.

The review section highlights the most important points that were included in the training section. It is important to present these main points in the training, and they may be used as a guideline for the presentation.

Attendance sheets are at the end of the manual. These sheets should be used to document who has attended each training. The attendance sheet includes a spot for the training topic, the date training occurred, the participants, and any comments about each participant. For example, the trainer could note if a specific participant was able to demonstrate a safety technique well. or if a participant struggled with understanding a training and needs additional individual training.

Steps for holding effective training sessions:

Notes for effective training:

It is at the discretion of the trainer to determine how they want to run the training session. Each section in this manual provides the basic information to be presented.

Because bison roundups occur infrequently and there are occasionally new people assisting, we suggest that you go through the pertinent training topics at the start of each day.

There are many different ways to teach information. The following page summarizes six teaching strategies that might be used during a training session.

To prepare for a training session, the trainer should review each section and determine which teaching strategy to use during the training.

The trainer should make sure that all materials are ready to go before the training begins, and that they include all of the most important points from the review section in the training.

Lecture

Lectures should be spaced with active learning strategies to energize workers. Lectures are useful for presenting new information and summarizing information from different sources.

Problem-based learning

Problem-based learning is a strategy that encourages the use of problem-solving skills and critical thinking. You can use this strategy by asking workers about problems specific to the job and then asking them to find solutions. For instance if the worksite is icy with rough terrain workers could be asked to identify problem areas and discuss methods that could reduce slips, trips and falls. This process provides workers the opportunity to analyze the problem, propose solutions and ultimately feel that they have contributed to the solving the problem.

Case studies

Case studies are narratives that can challenge workers to analyze a situation and express opinions about what should happen. Case studies bring real-world problems into the training. Case studies lead workers to actively participate and come up with innovative solutions. A manager could discuss an injury that occurred in the past and allow the workers to discuss how this could have been prevented.

Educational games

Educational games involve creating competitions between workers to reach a goal. Games teach but are also fun. An example of a game would be challenging workers to be the first to come up with 3 worksite safety improvements. This game would provide an opportunity for workers to carefully examine the work environment, use critical thinking and have input into safety improvements.

Role playing

Role playing can be used to help workers practice new skills. Situations can be written down, and a different role passed out to different people who can discuss the situation. They should be realistic and relevant to the job at hand.

Discussion

Discussions encourage workers to think critically about situations. To use discussion, managers can talk about a problem, monitor the discussion, and summarize the discussion when complete.

Background:

The proper environment and facilities are needed for a safe, injury free roundup. Some things that contribute to a dangerous working environment are dust; trip, slip, and fall hazards; lighting; and lack of worker escape routes.

Dust

Dangerous bacteria and molds exist in livestock dust. Breathing dust may lead to respiratory conditions like allergies or asthma in bison handlers. It is important to reduce the amount of dust that is inhaled during bison roundups. To reduce the amount of dust being inhaled, masks such as two strap NIOSH approved masks (N95 respirators) can be worn. Instructions for use on the packaging must be followed to ensure complete protection. Workers can decrease dust at roundups by spraying dusty areas with water.

Trip, slip, and fall hazards

Many accidents involving livestock handling are the result of slips, trips, and falls. To avoid slips, trips, and falls:

Escape routes

To avoid injury, workers must always have an escape route planned when working in close quarters with an animal. Having a worker serve as a watch-out and gate-keeper for the worker in the corral adds a layer of safety.

Appropriate number of workers

Generally, 5 or 6 people are needed to carry out a successful bison roundup. The number of people needed may be lowered by using low-stress bison handling techniques, a topic that is covered in a later section. Inexperienced workers must be supervised to prevent over-stressing the animals. If there are individuals present who are not actively engaged in handling the animals, it may be an indication that too many workers are present.

Chute width

Two options for lead up chutes are recommended. One version is approximately 6 feet wide allowing animals room to turn around. The other version is narrower, requiring that the animals move single file, providing no room for animals to turn around. In this instance, the size of the largest animal will determine the proper chute width. Wider chutes may lead to smaller animals being able to turn around in the chute. Using high-stress handling methods cause bison to rear up and turn around more frequently than using low-stress techniques.

Background:

Use of personal protective equipment (PPE) and safety equipment, such as fire extinguishers and emergency communication devices, are important to preventing injuries and seeking help if needed.

Proper PPE is necessary when working with bison. Wearing proper PPE will increase worker safety. Proper PPE for bison roundups is:

Apparel and conditions that are not appropriate for bison roundups include:

Loose items can get caught in machinery or disrupt the worker. Hair should always be pulled back, hanging jewelry should be removed, and loose or baggy clothing should not be worn.

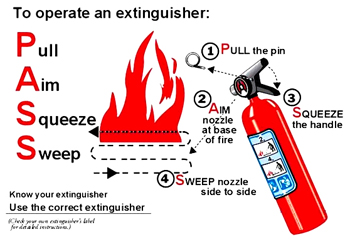

Safety equipment needed at bison roundups:

Background:

Bison handling can be stressful for the handlers and the animals. To reduce injuries to both bison and handlers, it is important to keep bison calm while working with them. This section goes over several areas important to low-stress bison handling: fear indicating behaviors, animal behaviors, noise, lighting, novel objects, and bison calves.

Fear indicating behaviors

Bison show fear behaviors as the result of being in a stressful situation. Not all animals react to stress the same. Some displays of fear in bison are:

| Low fear: | Increased fear: |

|---|---|

|

|

Animal behavior

Similar to cattle, bison have panoramic vision. They can see everywhere but directly behind them. Bison must be approached slowly from the side or front to avoid startling them. It is ideal to move bison forward by starting with the lowest amount of pressure to begin forward movement and to gradually increase pressure as needed. Starting with the lowest amount of pressure creates a calm experience for the animal. If movement is initiated with a large amount of pressure—for example, electric shock via cattle prod—the animal will immediately become increasingly fearful and display fearful behaviors.

Noise and movement

Bison are able to hear more sounds than humans. Subtle sounds, such as rustling papers or plastic bags, snapping fingers, pennies in a can, or a “shh, shh” sound are effective in moving animals forward. The handler should start with the least amount of pressure and increase as needed. The handler should pause between each attempt at increasing pressure so the bison can move calmly forward. The handler should use slow and deliberate movements.

Lighting and novel objects

Shadows can frighten bison. Lighting must be evenly diffused to avoid shadows. Novel objects like moving and flapping objects, such as coats hanging off of the fence flapping in the wind, can also frighten bison. Avoid hanging coats or other objects in the presence of the animals.

Mothers

Bison with their young have strong maternal instincts. The safest way to deal with this is to allow the young to stay close to their mother during handling. Workers should always move slowly and with caution when working with a cow and her calf.

Background:

Using syringes or needles is always a hazard because of the risk for needle sticks. It is important to handle syringes and needles correctly, and to dispose of them properly so that needle stick injuries do not occur.

To use animal medications safely:

Background:

All-terrain vehicles (ATVs) are commonly used in bison roundups to herd bison. ATVs can be extremely dangerous when not handled safely. Many people die each year while using ATVs for agricultural purposes.

Using ATVs to herd animals is particularly dangerous. This is often done by driving the ATV over uneven terrain at high speeds. This may lead to the front end of the ATV falling into a hole or hitting a rock. Turning quickly at high speeds can result in roll overs. Rolling over or flipping ATVs can result in injuries and even death.

Safety Suggestions:

Background:

Bison roundups may occur during dangerous weather including thunderstorms. Lightning and tornados accompany thunderstorms. Dark, greenish sky, large hail, a cloud that looks like a wall and a loud roaring sound are signs of an impending tornado.

Precautions to take:

Lightning fatalities rank second to floods in weather-related deaths.

Background:

Bison roundups may occur during cold weather. Frostbite, hypothermia, slips and falls pose hazards which bison workers must understand. Frostbite occurs when body tissue becomes frozen. Workers should be aware that skin that feels numb is too cold and in danger of further damage. Hypothermia occurs as the body’s temperature drops below 96 degrees. Extreme cold can produce weakness, drowsiness or confusion. Winter weather creates icy and muddy conditions. Footing is more difficult for workers and livestock. Animals being moved on slippery surfaces can injure themselves or fall on workers.

Safety Suggestions:

| Training Topic: | |

| Date: | |

| Participants: | Comments: |

Support for this document provided by the National Institutes of Occupational Safety and Health grant 5U54OH010162-05

This bison handler tailgate training manual was produced as a collaborative project between the University of Nebraska Medical Center (UNMC)- College of Public Health, University of Nebraska - Lincoln, the InterTribal Buffalo Council (ITBC) and the Central States Center for Agricultural Safety and Health(CS-CASH). Special thanks to Kelsey Irvine for her contributions to the research and production of this document.

For questions regarding this document or to order free copies please contact:

CS-CASH 402-552-3394 or visit the CS-CASH website: www.unmc.edu/publichealth/cscash.

Publication #: 5U54OH010162-05

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More