Farm Safety for Just Kids is a non-profit organization working to promote youth safety within the rural environment. This is done through the production and distribution of educational materials and the initiation of programs about farm and rural safety and health. Outreach coordinators and a chapter network of grassroots volunteers conduct educational programs to prevent health hazards, injuries, and deaths to children and youth. Tractor safety is one topic addressed by Farm Safety for Just Kids. A multitude of resources are available to teach a variety of topics such as machinery safety, livestock safety, chemical safety, and rural roadway issues.

Thank you for your interest in making the rural environment safer by teaching others about staying safe on the farm while around tractors. Please use the following guide to assist you in your Tractor safety program.

Feel free to contact Farm Safety for Just Kids at (800) 423-5437 or visit http://www.FarmSafetyForJustKids.org with questions or concerns.

This educational packet is designed to teach tractor safety to elementary through middle school students.

The material developed and disseminated by Farm Safety For Just Kids was peer reviewed and is intended for general information and educational purposes only. It should not be relied upon as medical or legal advice. If legal, medical, or other expert assistance is required, the services of the appropriate professional should be sought.

Copyright © 2015 Farm Safety For Just Kids

Reviewers:

Dr. Paul Ayers

Professor

University of Tennessee

George Cook

Farm Safety Specialist

University of Vermont Extension

LaMar Grafft

Associate Director

North Carolina Agromedicine Institute

Funding provided by:

Several topics or main themes arise when teaching children and youth how to stay safe while in the vicinity of tractors on the farm. Listed below is a chart of several suggested tractor-related topics to consider when planning tractor safety lessons. It serves as a general guide, but is not intended to be strictly followed as each child is unique in his/her own developmental stage and experience.

| Under 5 years old Rules and Concepts | 5 to 10 years old Rules and Concepts | 11 to 13 years old Rules and Concepts | Working Youth | |

|---|---|---|---|---|

| Extra Riders on Tractors | Never ride on a tractor | Understand the physical dangers of being an extra rider | Understand the health hazards to themselves as extra riders, as well as for the tractor operator | Both riding on a tractor and allowing passengers is risky. Both practices should be discouraged |

| Falling from Tractors | Do not climb on tractors | Understand the consequences of falling off a tractor | Understand the repercussions of falling from a tractor | Take precautions such as cleaning steps, and wearing non-slip shoes |

| Tractor Proximity | Always stay away from tractors | Notify the tractor driver of your presence when nearby. The driver may not be able to see you | Notify the tractor driver of your presence when nearby. The driver may not be able to see you | Be alert when driving tractors for the sake of those close by |

| Tractor Safety Features | Information is inappropriate for this age group | Identify moving tractor parts and shields that protect people | Understand tractor features that impact safety | Understand and use tractor safety features to protect yourself |

| Tractor Implements | Stay away from all working and non-working tractor implements | Stay away from working tractor implements | Understand why implements can be hazardous to both the operator and any bystander | Hitch implements with caution and follow safe procedures when operating a tractor |

The main objective of educating children, especially young ones, about tractor safety is to teach them to stay away from tractors. Tractors hold potential hazards not only to the driver, but to those in close proximity. As children grow and develop, they begin to understand abstract concepts. Rules for very young children are black and white, while rules for older children, who are beginning to understand more are based on comprehension and complexity of the hazard. This allows them to begin to connect the concept of hazardous mechanisms, resulting hazards, and possible injuries. If children understand these hazards, they are more likely to follow the rules that are intended to keep them safe. The lesson plans included in this educational packet have a suggested age for each activity. Many of the activities can be adapted to other age groups by simplifying or adding more details.

This manual is intended to be used as a reference guide when conducting programs about tractor safety. It can be used when instructing young children about the dangers that tractors pose to them as bystanders or extra riders. This information is also useful when youth first begin to learn about driving a tractor.

This manual is not intended to replace safety training or certification courses; instead it helps children too young for certification training courses to understand the dangers and ways to prevent injuries.

The puzzle section complements certification classes and other instruction while this educational information helps the instructor to understand the dangers present in each situation. Read the educational information before conducting lesson plans, playing interactive games, giving a PowerPoint presentation, or distributing work sheets. Use the questions within each section to engage students in discussion and increase learning and retention.

There are guidelines that help parents and employers determine the appropriate time for youth to begin operating a tractor. The North American Guidelines for Children’s Agricultural Tasks (NAGCAT) were developed to help adults match up a child’s unique physical and mental abilities with the tasks involved in completing different agricultural jobs.

Check with your local extension office, Vo-Ag instructor, state agricultural university, and implement dealers for additional tractor safety resources. A listing of specific web-based resources is included at the end of this section.

Tractors play a major role on the farm. Since tractors took over the work load of horses and mules in the fi rst part of the 20th century, they have made a major impact on modern agricultural production. Tractors are the most common piece of farm equipment. They transport equipment and material, pull implements, and provide power for other equipment.

Tractors are intended to assist operators in doing work on the farm. They can be large and very powerful. Their size and strength can be the source of harm when not used properly. Tractors are used on rough, uneven ground and can make sharp turns. If this is done at high speeds, or by an untrained operator, it can cause injury.

Agriculture, mining, and construction are ranked as the top three most hazardous industries in the United States. Tractors are involved in approximately 32% of the agricultural related injuries, with 44% of U.S. tractor-associated deaths related to overturns specifically.

The leading source of fatal injuries to children on the farm is machinery which includes tractors. Tractor overturns, runovers, power take-off (PTO) entanglements, and collisions with non-farm vehicles on public roads are the leading causes of farm related death and serious injuries in the United States. Each year, more than 250 farmers, their family members and employees die as a result of tractor-related incidents. Half of these deaths occur when a tractor overturns and crushes the operator. The University of Kentucky estimates that 4.46 non-fatal injuries from overturns occur for every fatality.

Tractor overturns are major causes of injuries and deaths to tractor operators. When this occurs, people are seriously impacted physically and they also experience property damage, medical bills, loss of work time, and reduced productivity. On the farm, tractors cause more deaths (36%) than any other item.

For example, in Ontario, Canada, 244 people died as a result of tractor-related incidents between 1980 and 1994. This accounted for almost 48% of the total fatalities for that period. The vast majority (about half ) of these deaths were fatalities caused by tractor overturns to the side or the rear.

Side overturns usually take place when the tractor is being used on sloped surfaces. As the slope increases, the chance of a side overturn is greater. The center of gravity is altered toward the downward slope. The chance of a side overturn also increases if obstacles and rough surfaces or pot holes are being driven on. Side mounted implements also increase the chance of side overturns. Keep side mounted implements on the uphill side of the tractor to increase stability. Avoid turning on a slope, if possible, or turn downhill, if you must. When driving close to a ditch or embankment stay as far away from the edge as possible. The weight of the tractor can cause the ground to give way.

Rear overturns sometimes take place when implements are improperly hitched behind the tractor. If a chain or rope is hitched too high on the tractor when pulling something out of the ground, the tractor can be pulled over backwards. This can also happen if there is not enough weight on the front of the tractor. Weight can be added to the front to prevent the tractor from tipping backward. If a rear overturn takes place, there is only 1.5 seconds to react and not enough time to escape from the weight of the tractor.

Overturns can also take place when driving up a steep slope. If brakes are applied to decrease the speed of the tractor, the tractor can pivot on the back axle causing the front end to rise. The steeper the slope, the greater the danger. When driving across a hill where the stability of the tractor is uncertain, turn the tractor toward the downward slope. A sudden uphill turn is more likely to cause tipping.

Another cause of overturns is driving out of mud or ice. If the back tires are stuck, the front end may raise up causing the tractor to tip backwards. Back the tractor out when it is stuck.

Runovers can occur when the operator/passenger falls from the tractor, or another person is runover by the machine’s tires. Many youth are killed each year in this manner. Always wear a seatbelt in the presence of a ROPS and make sure the area is clear of others before starting the tractor to prevent a runover.

Tractor overturn/runover prevention tips:

QUESTION & ANSWER

Q: If you have a younger brother or sister, how can you help protect them from being involved in a tractor runover situation?

A: Children, especially young ones, are often not seen by tractor drivers due to their small size. Older siblings can watch smaller children when on the farmstead preventing them from approaching a tractor.

Hydraulics can lift heavy hay bales; raise steel implements; or lift machines off the ground. How can a small device produce so much power?

Hydraulic systems use pressure built up by fluids within a small space. Any liquid can be pressurized but some work better than others. Complete Activity 5 to demonstrate that even water can be pressurized.

Oil is used as the liquid with tractor hydraulic systems. As the hydraulic fluid moves through a closed system of hoses, the fluid meets resistance, pressure increases, and heat up as the friction builds. Pressure within the hydraulic system can exceed 2,000 pounds per square inch (psi). This pressure is used to lift items such as loader buckets and implements.

The tremendous pressure is where the danger lies. With this much pressure, pin-hole leaks can develop in the hoses. The hydraulic fluid (oil) is forced in very small hoses with small openings. If a hose breaks or cracks, the oil will release with strong force. This force is powerful enough to damage human tissue by injecting oil under the skin causing a medical emergency.

The following precautions should be taken when around hydraulic systems:

QUESTION & ANSWER

Q: What are the main hazards of being around tractor hydraulics?

A: Released pressure from a faulty hose or poor connection is the major hazard of tractor hydraulics. Heat produced by the pressure is another hazard associated with hydraulics. These hazards may not be observable at first glance.

Q: As a youth, what is your role in preventing injuries related to hydraulic systems?

A: Understanding the mechanics of a hydraulic system should be sufficient to warn youth that they should stay away from hydraulic hoses. Do not touch any hose, but tell an adult if you notice that a hose is deteriorating.

Allowing extra riders is one of the leading causes of fatalities associated with tractors, especially among children and youth. Most tractors are designed for one person. If an instructional seat is built into the cab it is intended to be used to teach someone to be a tractor driver. Extra riders put themselves and the driver at risk. The extra rider is exposed to the same dangers as the operator. The extra rider distracts the operator when he or she is trying to concentrate on driving; can block access to control panels; and can obstruct the operator’s view.

Falling from the vehicle is one of the most dangerous results of being an extra rider. An unexpected bump or turn can cause the rider to fall under the tractor’s tires. Death can occur when the rider falls and the tractor’s wheels or trailing implements run them over.

A tractor cab can give a false sense of security. Deaths and injuries can occur when the rider falls from an enclosed cab. Cabs can reduce, but not eliminate, the risk of harm.

Additionally, both the tractor operator and the extra rider can be exposed to health risks. The vibration of the tractor has the potential for jolting bones, muscles, and organs. The constant movement for the passenger, especially when traveling in bumpy fields, may have long term effects. The noise of a running tractor can damage hearing if exposure occurs for long periods. The tractor can have a decibel level of 85 to 100 if the door is open which is comparable to loud rock music. Hearing protection should be used.

Dust from working in the fi eld can fi lter into your lungs while you breathe. Extended exposure to dust, pesticides, or other particles can lead to respiratory damage. Wear a respirator mask when appropriate.

Tractors are designed for work, not passenger transportation. Walk, ride a bike, or ride on the inside of a pickup cab with a seatbelt, if you have to get from one location to another. Make a lifetime policy to never allow extra riders on tractors. When old enough to drive a tractor be smart, use caution, and refuse to allow your friends to ride on a tractor with you. Place warning decals on the tractor fender to remind everyone of the dangers of riding on a tractor.

Parents and adults can help prevent injuries among youth by following these rules:

Tractors, like many machines on the farm, perform functions that can be dangerous if safety precautions are not followed. The chart on page 10 lists specific hazards, an explanation of the hazards, and ways to prevent injuries.

Activity:

Use the information in the chart on page 10 to complete the Mechanical Hazards Match Up on page 58 in the puzzle section.

The leading source of fatal injuries to youth (23%) involves machinery, including tractors. Young youth may not be directly involved with these hazards but they need to know the potential risks around tractors. If you see a warning sign, stay away from the machine. Decals and symbols identifying hazards are often placed on the tractor (see examples below).

QUESTION & ANSWER

Q: What should you do if you see that a guard is missing on a rotating object such as a PTO or a fan blade on the tractor?

A: Do not go near the object, especially if it is running. You could get caught in the spinning mechanism. Tell an adult about the missing guard.

Q: Why are pictures used to identify diff erent mechanical hazards?

A: In a situation where there are potential hazards, it is important to recognize the dangers quickly. Pictures are more easily and quickly recognized than written words. Images are universally understood in case operators cannot read English.

Falls from tractors are common and preventable. Falls can take place from a moving or stationary vehicle or machine. Make sure all steps and platforms are clean and free from grease, ice, manure, water, and other debris. Slipping on these substances can cause a person to fall. Use hand rails and steps when climbing aboard or down from the tractor. Wearing slipresistant shoes will also help prevent falls.

Jumping from a tractor, whether it is moving or not, can be dangerous. Clothing items can get caught on levers or other protruding parts causing the tractor to lurch into motion. Broken bones can result if you land incorrectly. If the tractor is moving, the operator can fall in the path of trailing implements which can cause death.

When operating a tractor with a rollover protection structure (ROPS) use a seatbelt to protect yourself. Never try to get off the tractor while it is moving, even when it is moving very slowly.

Use hand rails and steps, facing the tractor, when climbing aboard or down froma tractor. High speeds can cause the operator to fall from the tractor, especially if turning corners sharply or driving over obstacles.

Fall prevention tips:

QUESTION & ANSWER

Q: What is the worst thing that could happen if you fall off a tractor?

A: Death can occur if you fall off the tractor while it is moving. A tractor can weigh several tons. If you get run over by the tractor tire, you could be crushed.

Q: As a youth, what things can you do to prevent falls from tractors?

A: Clean manure and other debris off tractor steps; refuse to ride on a tractor as a passenger; and wear slip-resistant shoes, if operating a tractor.

Q: What type of clothing should be worn when driving tractors?

A: Close fitting clothing without dangling strings or flapping cloth will help prevent getting caught in moving parts or tripping. Wearing slip-resistant shoes will help prevent falls.

Tractors and other vehicles must share the road. During busy seasons, many tractors and implements are being transported from one location to another. Tractors travel at a much slower speed than motor vehicles like automobiles, pickups, and trucks. This difference in speed can create problems for both vehicles, especially combined with the characteristics of rural roads such as hills, gravel, narrow shoulders, decreased visibility at corners, and steep grades.

The short closure time of a fast approaching vehicle behind a slow moving tractor often does not give the driver of the faster vehicle time to react.

| Hazard Name | Explanation | Dangers | Prevention |

|---|---|---|---|

| Pinch Point | Two parts move together and there is a possibility that a body part could be caught between them. | Body parts that get caught can be cut or crushed; loose clothing that gets caught can pull body parts into the mechanism. | Stay away from moving objects. Keep shields in place. |

| Wrap Point | Rotating components, such as a PTO. | Clothing caught by the spinning shaft can pull a person into the mechanism. | Keep shields in place and shut off power before approaching the mechanism. |

| Shear Point | Two machinery parts move across each other. | An object in contact with the metal parts can be cut. | Turn off machine before approaching. |

| Crush Point | Two objects moving toward each other or one moving object hits a stationary object. | Body parts can be crushed by the moving part or dropped item. | Do not stand in a position where you could be caught and block all joints so the object can not move. |

| Burn Point | Heat from hot objects can burn fl esh. | Hot muffl ers, pipes, and hydraulic fl uids can burn a person. | Do not touch the engine or other potentially hot objects. Carefully place your hand near the object to feel if it is warm. |

| Pull-in Point | Rotating objects that come in close contact with each other. | Rollers can pull a person into the mechanism. | Shut down the machine before making repairs or adjustments. |

| Stored Energy | Energy released when an object is unconfi ned, for example, a pressurized system. | Released energy or pressure has enough force to damage the body, if struck. | Avoid areas where spring loaded devices are present. Stay away from hydraulic hoses. |

| Thrown Object | Blades and other rotating devices can propel objects that come in contact with the spinning blade. | Objects that hit people have the potential to bruise, lacerate the skin, or deeply cut flesh. | Wear eye protection around rotating blades. Keep bystanders away. |

One of the key safety features on a tractor is the rollover protective structure (ROPS). When ROPS are used along with seatbelts they can virtually eliminate death and serious injury. Unfortunately, only half of the approximately 4.7 million agricultural tractors in the United States have ROPS. In 2012, 59% of tractors used in the US were equiped with ROPS.

Since ROPS were introduced to the general public in the 1970s, many lives have been saved during tractor overturns. Rollover protective structures are designed for each specifi c tractor and must meet national and international standards. ROPS protective frame and crush resistant cab, when used in conjunction with a seatbelt, can reduce the number of serious and often fatal injuries to tractor drivers. The seatbelt holds the operator within the protective frame if an overturn takes place. When used with a seatbelt, a ROPS is 99% eff ective in preventing deaths in tractor related incidents.

ROPS are either a two-post type or built within an enclosed cab when manufactured. The two-post type can be either rigid or foldable which have hinges to allow it to fold down for low clearance areas.

Most overturns are associated with farm-related activities such as driving over hazards like rocks, stumps, and holes; running into ditches; hitching high on the tractor when pulling implements; driving up steep slopes; and operating front-end loaders.

A person riding with the tractor operator, even in a tractor with a cab, is not fully protected by ROPS, especially if not wearing a seatbelt. Extra riders have been thrown against a door, releasing the latch and being ejected from the cab. Often these types of incidents result in the rider’s death.

Overturn injury prevention tips:

QUESTION & ANSWER

Q: What should you do if you come upon a person that has just experienced a tractor overturn?

A: Get help as soon as possible. Call 911 from the closest phone and give explicit directions to the location.

Every tractor and self-propelled farm vehicle that uses the public roads at a speed less than the normal speed of traffic (most states define this as under 25 MPH) should have a slow moving vehicle (SMV) emblem. Check with your state department of transportation to determine your state’s speed limit requirements. Towed implements may need the same type of emblem. SMV emblems are made of specially designed, reflective material that is visible from a great distance. The emblems can be seen during the day and become even more bright when motor vehicle headlights shine on them at night.

SMV emblems are to be placed in the center of the tractor or implement and should be fastened between 2 to 10 feet above the roadway. They must be visible from a distance of at least 150 meters. SMV emblems fade in time due to sun and weather exposure. When this happens, replace the SMV emblem. When the SMV emblem becomes dirty, wash it.

Activity:

Complete the SMV emblems activity on page 25 in the lesson plan section to learn about the reflexivity of these signs.

QUESTION & ANSWER

Q: Why are the colors of florescent orange and red used on slow moving vehicle emblems on the back of the tractor?

A: These colors are highly visible during daylight hours. At night, the dark red border creates a hollow, red triangle which is very reflective when headlights from other vehicles hit the emblem.

Q: What can you do to increase the visibility of SMV emblems so your family’s tractor is noticeable while driving on public roads?

A: Wash the SMV emblem with soap and water to remove dirt and other road debris.

Lights on tractors are required from one-half hour before sunset to one-half hour after sunrise. During this time period, the tractor operator cannot see clearly to drive and other vehicles cannot see the tractor. Tractors must have sufficient lighting that can be seen from a distance of 1,000 feet. A white light in the front of the vehicle is required. On the back of the tractor, there should be two red lights as wide as the machinery and on the highest part of the tractor there must be two flashing, amber lights. These lights are in addition to the SMV emblem on the back, middle section of the tractor.

QUESTION & ANSWER

Q: What might happen if the lights on a tractor are not working?

A: Other vehicles on the roadways could not see the tractor at night and may collide with it.

Friction and fuel combustion of dried plant material can lead to a fire on tractors. Small, portable fire extinguishers are available for use on the tractor if a fire should start. It is important to have a multi-class, most commonly an ABC, fire extinguisher. See the chart below.

| Class | Symbol | Type of Fuel |

|---|---|---|

|

Green triangle | Ordinary, combustible (i.e. plant foliage) |

|

Red square | Flammable liquids and fuels |

|

Blue circle | Electrical equipment |

|

Yellow star | Combustible metals |

QUESTION & ANSWER

Q: As a youth, how can you protect your parents if a tractor fire should take place?

A: A multi-purpose fire extinguisher would make a great Christmas or birthday gift for your parent, grandparent, or guardian.

Q: Which class of fire extinguisher would probably not be needed on a tractor?

A: Class D (yellow star) would probably not be needed on a tractor. The other types of fuel are integral to tractor operation and therefore could start a fire.

While having a fire extinguisher aboard all tractors is a great asset, some upkeep is required. Be sure to check the expiration date, recognize that the pressure gauge needle is within the green area, and pressure test fire extinguishers every 5 to 6 years.

A pre-operational check of the tractor done by an adult will help ensure that mechanisms on the machine are working properly and safely. A safety “walk around” will identify items around the tractor that need to be addressed before operation. Make sure the tires are not frozen to the ground or stuck in mud. Remove any loose items such as tools laying on the tractor or platform. Check for any obstacles such as toys, large stones, or boards that may be run over if the tractor begins moving. Many of these items cannot be seen from the operator’s seat. It is especially important to make sure no children or other bystanders are present.

After doing the “walk around” it is now time to check the operating features of the tractor. Check these specific items on the tractor:

It cannot be emphasized enough that checking for people around the tractor is essential to prevent runovers. While in the driver’s seat, the operator may not be able to see or hear others on the ground, especially if they are small children. There have been many fatalities due to children playing close to the tractor or trying to approach the tractor operator.

QUESTION & ANSWER

Q: What can children do to help ensure the safety of tractor drivers?

A: The best way children can help everyone be safe is to stay away when someone is performing a tractor check. An adult may not see a small child that gets in the way or could be distacted from his/her work.

Tractors, like any machine or vehicle, need regular maintenance to keep them running smoothly and safely.

Operating and repairing tractors is an adult responsibility, but youth can help by telling someone about problems they may observe on a tractor. Often when tractors are being repaired, they are jacked up and wheels are removed. This process can be dangerous to the worker and anyone close. All children and other bystanders should keep their distance.

Youth can help with tractor maintenance by:

QUESTION & ANSWER

Q: Why should tractor repairs be done by an experienced person?

A: Tractors are valuable farm equipment and need to be protected from inappropriate actions that could cause damage. The mechanics of the tractor can be complicated. Someone with experience and knowledge should be conducting repairs and maintenance to protect the machinery and the individual from harm.

Q: What are some other things that might be found when conducting a tractor pre-operational “walk around”?

A: Items laying on the ground, such as tools that have fallen off the tractor or bolts that are not securely in place, may be found and should be repaired before operating the tractor.

A tractor’s stability can be altered by a change in its center of gravity (COG). COG is the point where weight is most evenly distributed.

Tractor overturns ususally occur when driving on a slope, over bumps, too fast, or using a front end loader. It happens when the COG is altered too much and the tractor tips beyond a point of no return.

To demonstrate COG, try balancing a pencil on your fi nger. When the pencil balances without falling, its weight is evenly distributed. If weight is attached to the tractor, or the tractor is hauling heavy items such as large, round hay bales, the center of gravity is altered just like adding a heavy eraser to the end of the balancing pencil.

Activity:

Complete the Tractor Stability activity on page 35 in the lesson plan section.

QUESTION & ANSWER

Q: What precautions can be taken to prevent injuries due to a tractor overturn?

A: ROPS protect the tractor driver but not an extra rider if they were on the tractor. Seatbelts hold the driver within the protection zone provided by the ROPS. Driving slowly around curves, on hills, and rough terrain will help prevent overturns.

Q: Why is it important to understand the center of gravity concept before operating a tractor?

A: It will help the driver operate the tractor more cautiously over bumps, on slopes, and encourage them to adjust speeds.

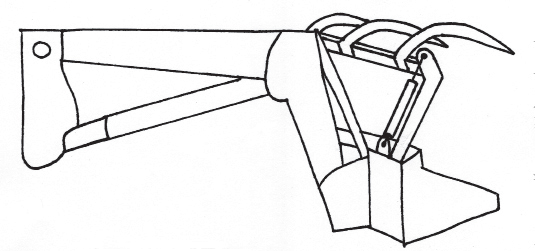

Front end loaders are used quite extensively on many farms to transport feed, gravel, manure, soil, and other items. The heavy load at the front of the tractor alters the center of gravity and the stability of the vehicle. This can lead to a tractor overturn if the operator does not know how to correctly compensate for the change in weight distribution. If the loader bucket is too high, unsecured materials in it can fall and injure the driver. To safely use a front end loader:

QUESTION & ANSWER

Q: What precautions should youth take when in close proximity to farm implements?

A: Due to the size and weight of farm implements, everyone should stay away from any moving equipment. The loader bucket could fall or its load could be released so never stand in front of or under front end loaders.

In many locations there are no restrictions on the number of wagons or trailers being towed at one time by a tractor. The tractor driver is responsible for making sure the implements are securely connected to the tractor. This may require the use of a safety chain to attach the tractor and implement when on the road.

QUESTION & ANSWER

Q: You may be asked to line up and attach an implement to a tractor. What precautions should you take to prevent injuries?

A: Say no, you’re too young to hitch an implement to a draw bar. Parents can check with the North American Guidelines for Children’s Agricultural Tasks (NAGCAT) to determine a child’s ability to safely perform this task.

Power Take-Off s (PTO) are used on the farm to transfer power from the tractor to another implement such as a grain auger, manure spreader, mower, or feed grinder. They are found on most tractors. PTOs operate by turning at speeds of 540 or 1,000 rotations per minute. This speed and the device make the PTO very dangerous. An entanglement can occur in the driveline between the tractor and the implement and can cause some of the most serious injuries on the farm. Equipment manufacturers provide shields for PTO drivelines to protect operators and bystanders from becoming entangled in the rapidly spinning shaft.

PTO Related Injury Prevention

QUESTION & ANSWER

Q: Why can a PTO be dangerous?

A: The speed of the spinning shaft makes it hazardous because if something gets caught in the shaft it can pull body parts into the spinning shaft.

Q: How do you know if a PTO shield is properly installed and intact?

A: Never go near a rotating PTO whether it is shielded or not. When looking at a shielded, non-operating PTO, you should not see the rotating shaft, protruding screws, or jagged edges. Tell a parent or adult if you see any of these safety hazards.

Tractors come with operator’s manuals intended to help the operator become familiar with the controls, gauges, and maintenance as well as safe operating procedures to be followed. All family members should know how to turn off the tractor and other equipment. Keep the manual in a convenient location on the machine for quick reference. If the manual has been lost, contact the manufacturer and request a new one.

Training and education are needed to drive a tractor safely. A tractor is a very powerful machine and should be treated with respect. Many youth are allowed to operate a tractor at a young age. It is important that they have the knowledge, skills, and abilities necessary to prevent injury and death. The North American Guidelines for Children’s Agricultural Safety and Health (NAGCAT) have been established to help parents recognize the characteristics needed before children are assigned jobs on the farm, like operating tractors.

The US Department of Labor determined tasks which youth, ages 14-15 years old can leagally perform for hire if certified. Certification courses are available to teach youth to be safer and more skilled tractor and machinery operators on the farm. Classes are taught by Extension personnel or agricultural educators. Call the local Extension offIce to find classes offered in your location. State and federal laws restrict youth from being employed to carry out certain hazardous activities or require certification to work off the family farm as well. These restrictions do not apply to youth working on their own farm but the necessary safety precautions do. Simply completing the recommended course work does not ensure the safety of young tractor operators. Supervision by a safety-minded adult is a must, especially when novice youth are first learning to operate the tractor.

The US Department of Labor identifies specific types of farm and ranch work that are classified as particularly hazardous for youth working under the age of 16.

These hazards include:

Employers can be fined if they hire youth under 16 to do these hazardous jobs if they have not successfully completed a certification course.

Activity:

Complete the Agricultural Hazardous Tasks activity on page 21 in the lesson plan section.

QUESTION & ANSWERS

Q: What other situations impair a person’s ability to safely operate a tractor.

A: (1) Using alcohol or drugs impairs the operator’s ability to think clearly and slows down the reaction process when unforeseen situations take place. (2) Having other people riding with the tractor operator distracts the driver and may cause him or her to lose concentration when driving. If an unforeseen situation takes place (hit a hole, tire blows, run into a rut, etc.) the driver may not be capable of quickly and safely handling the situation. (3) Lack of knowledge and experience handling tractors may cause incidents if the operator does not have an understanding of what to do in the case of an unforeseen situation.

Conducting surveys of your intended program audience can identify their knowledge about tractor safety. If the surveys are done before an educational program takes place, it will give the presenter a basis for where his/her audience is in relation to tractor safety. The educational program can then target issues lacking by the audience.

The surveys can be conducted again after the program has taken place in a pre and posttest format. This will identify change in knowledge. The resulting information could make a great newspaper article when reporting the changes made by your audience.

Listed on page 19 are questions related to the information in this packet. Take into consideration what topics you plan to cover in your presentation and program. If you will not be covering hydraulics, don’t use the questions related to this topic. The questions can be combined or rewritten to be specific to your program.

Surveys can be completed and tabulated several ways. They can be copied, distributed, completed, collected, and tabulated by hand if there are only a few surveys. If many surveys will be completed, an easier way to complete the process is using an electronic software package; some of them are free if you want only basic analysis results. Use their suggestions to ensure a good response rate.

ANSWER KEY: 1:b, 2:a, 3:d, 4:d, 5:d, 6:c, 7:b, 8:a, 9:c, 10:b, 11:c, 12:a, 13:d, 14:b

The self-assessment tool can be used to identify behaviors used by your audience. If used before your presentation, it can be used to identify areas that need special attention. If used after the program, it can be used to see if your audience has changed their behavior when compared to the assessment done prior to the program. This information is self-reported so there is a chance the information may be slanted.

| Always | Sometimes | Never | |

|---|---|---|---|

| I do not allow passengers when operating a tractor | |||

| I do not ride with others when they are operating a tractor | |||

| I model safe behavior around tractors when children are present | |||

| I place warning decals on tractors | |||

| I have successfully taken a tractor certification course | |||

| I do not step over an operating PTO shaft | |||

| I report when a shield is defective or missing | |||

| I clean tractor steps and platforms when dirty | |||

| I clean dirty SMV emblems | |||

| I report when SMV emblems are faded | |||

| I use hand rails and face the tractor when climbing aboard | |||

| I do not jump from or exit a moving vehicle | |||

| I tell an adult about strange noises made by the tractor |

| Organization | Web Link | Content |

|---|---|---|

| US Department of Labor | https://www.dol.gov/whd/state/agriemp2.htm | Listing of state specific agricultural child labor laws |

| USDA Extension Service | https://extension.org/ | Listing of extension resources – search for tractor safety |

| National Ag Safety Database | http://www.nasdonline.org/ | Listing of farm safety and health resources – type in tractor safety |

| CDC/NIOSH | http://www.cdc.gov/niosh/topics/aginjury/ | Fact Sheets |

| NIOSH Agricultural Safety and Health Centers | http://www.cdc.gov/niosh/oep/agctrhom.html | Projects and research about farm injury prevention, including tractor safety |

| Pennsylvania State University | http://extension.psu.edu/business/ag-safety/youthsafety/nationalsafe-tractorand-machineryoperation-program | National tractor and machinery certification course material |

| Purdue University | http://www.gearingup.info/ | National tractor and machinery certification course material |

Don’t forget to utilize local insurance companies, farm equipment dealerships, safety videos on YouTube, and universities in your state.

CDC/NIOSH. (2006). NIOSH awards funding to Ag Research Centers for initiative to reduce tractor deaths and injuries. Available at: http://www.cdc.gov/niosh/NPPM/upd-03-21-06.html

Donham, KD, Osterberg, M, Myers, M, & Letola, C. (1997). Tractor risk abatement and control. Policy Conference Final Report, 4-13. Iowa City, Iowa: University of Iowa.

Hard, DL, Myers, JR, & Gerberich, SG. (2002). Traumatic injuries in agriculture. J. Agric. Safety Health 8(1): 51-65.

Heaney, CA, Wilkins, JR, Dellinger, H, McGongle, H, Elliot, TL, & Jepsen, SD. (2006). Protecting young workers in agriculture. Participation in tractor certifi cation training. J. Agric. Safety Health 12(3): 181-190.

Jenkins, PL, Sorenson, JA, Yoder, A, Myers, M, Murphy, D, Cook, G, Wright, B, Beyes, JJ, & May J. (2012). Prominent barriers and motivators to installing ROPS: An analysis of survey responses from Pennsylvania and Vermont. J. Agric. Safety Health 18(2), 103-112.

Jepsen, SD. (2012). The U.S. Department of Labor’s tractor and machinery certifi cation program: management styles and perceptions held by community stakeholders and instructors. J. Agric. Safety Health 18(3): 217-32.

NIOSH. (2014). Agricultural Safety. Available at: http://www. cdc.gov/niosh/topics/aginjury/

NIOSH. (2007). Injuries to youth on U.S. farm operations, 2004. Available at: www.cdc.gov/niosh/docs/2007-161/

NIOSH. (2004). National Agricultural Tractor Safety Initiative. E. Swenson, ed. Seattle, WA: University of Washington, Pacific Northwest Agricultural Safety and Health Center.

NIOSH. (2010). Worker safety on the farm. Available at: http:// www.cdc.gov/niosh/docs/2010-137/

Ontario Farm Safety Association. (2002). A guide to safe farm tractor operation. Available at: http://nasdonline.org/1650/d001534/a-guide-to-safe-farm-tractor-operation.html

Penn State Extension. (2014). National safe tractor and machinery operation program. Available at: http://extension. psu.edu/business/ag-safety/youth-safety/national-safetractor- and-machinery-operation-program

Concept: This activity investigates and clarifies participants’ attitudes concerning children when they are around tractors. It helps participants discuss different views to sensitive issues in a nonthreatening format. Statements are designed to be progressively more controversial to foster discussion. If young children participate in this activity with their families, an adult may need to help them understand the concept of “level of agreement” and translate their answers into numerical values.

Targeted Age: Adults, families, and youth

Time: 30 to 45 minutes

Ask each participant to number from 1 to 9 (more or less if using diff erent statements), on a piece of paper. Read the following statements out loud. After each statement, have each person place a numerical value from 1 to 10 as to their level of agreement. Ten equals the most agreement and one equals the least agreement.

Statements:

Explain that one wall of the room is a continuum with 1 at the far left and 10 at the far right. All other numbers fall in between. Taped numbers on the wall will help. With answers in hand, have participants walk to the number corresponding to their answer for number 1. Do not re-read the statement until everyone is positioned. Encourage people to be honest and not go with the crowd. Allow time for discussion after each statement. When you are finished with statement one procede through the list until each statement is addressed and the students have moved many times along the wall.

This activity will spur good interaction and discussion about attitudes toward tractor safety. Explain that there are no right or wrong answers.

Facilitator – Ideas to be brought out during discussion:

Objective: Identify hazardous jobs on the farm that youth under the age of 16 should not be doing.

Concept: This activity is designed for youth before they start working on the farm. It is important for youth to know which farm tasks they should not be performing. The size, power, and mechanisms of tractors and farm machinery can cause injuries if proper precautions are not taken. Youth are at high risk; they do not have the size, strength, knowledge, and training necessary to safely perform certain tasks and operate specific machines.

Federal laws regulate that no youth younger than 16 years old perform specific tasks off the farmily farm without attending a tractor certification class. These tasks are shown in the pictures on pages 22-24. The laws only apply to situations where youth are employed for work. If youth are working for their parents the laws do not apply, although the identified situations and equipment are just as dangerous. It is wise for youth to stay away from dangerous situations no matter who they are working for.

Targeted Age: Junior high school students, parents, and employers of youth workers

Time: 30 to 45 minutes

Material: Pictures of tractors and farm machinery identified in the hazardous occupational act. (Larger, colored pictures can be found on the internet or in farm magazines.)

Identify agricultural dangers, especially those most harmful to youth. The items in the charts on pages 22-24 represent each of the dangers that are outlined by the US Department of Labor. Fill in the charts with the hazards associated with each item.

Discussion: Have students share stories that show how youth can become injured while performing dangerous tasks. Ask the students to explain how the person was injured (body part, injury severity, work setting, etc.). Give suggestions about preventing a similar incident.

QUESTION & ANSWER

Q: Are there laws that prevent youth from being employed on a farm?

A: Yes, federal law states that youth under the age of 16 cannot work for hire performing some hazardous tasks.

Q: List jobs on the farm that aren’t prohibited, therefore allowing youth to work for hire while doing these tasks.

A: Mowing lawns, picking berries, feeding hogs, repairing fences, loading hay, milking cows, painting, etc.

Q: There is a certification course that helps youth age 14 and 15 learn about working on the farm safely. What farm jobs can youth perform more safely because they took the certification course that otherwise they could not?

A: Youth can safely operate a tractor over 20 hp, combines, grinder, tillers, and other machinery because they took a certification course.

Q: Where can you find out about the certification course?

A: Call your local Extension office or FFA advisor and ask when and where the courses take place.

Q: The certification course targets what age group?

A: The course is designed for youth between 14 and 16 years old. Other youth can take the class for their own well-being or if their parents want them to learn how to be safer on the farm.

| Identified Hazards | Why are youth at increased risk? | |

|---|---|---|

Tractor over 20 hp |

Example: The power of a tractor is greater than most other vehicles on the farm. | |

General machinery |

||

Specialized machinery |

||

|

||

|

||

|

||

|

||

Transport (tractor with passenger) |

||

|

||

|

||

|

||

|

Objective: Visualize the importance of clean, bright slow moving vehicle (SMV) emblems for tractors and other farm vehicles used on public roads.

Concept: Farmers often use public roadways to move large farm machinery and tractors from one location to another. Large farm equipment travels at much slower speeds than cars and pickups. SMV emblems are made of reflective materials and are attached to the back of farm machinery to alert faster vehicles to slow down in order to avoid a collision.

Targeted Age: Upper elementary school students and above

Time: 30 to 45 minutes

Materials:

This activity should be done in a large room where you have the ability to turn the lights off and cover the windows with curtains or shades.

Cut various colors of construction paper into long, rectangular strips. Tape all strips of paper and similar strips of reflective tape on one wall of the room. Have all the students move ten feet away from the wall. Turn out the lights. Shine the flashlight beam on each object. Compare similar colors of different materials (red construction paper and red reflective tape). Compare different colors of the same material (red and orange reflective tape). Use additional colors (blue, green, etc.) to demonstrate why red and orange were chosen for the SMV emblem. Keep track of which colors and materials are the most visible. Turn on the lights and rearrange the strips in the order of least to greatest visibility. Have the students move as far away from the taped strips as possible. Turn out the lights again and shine the flashlight onto the strips. Compare the visibility. They should be in the order of least to most visible. If not, rearrange to reflect the group’s choices.

Place mud on a part of each reflective strip and tape. Turn off the lights and observe what the mud does to the reflexivity of each strip. If you have new and old SMV emblems, repeat the demonstration comparing the faded and new emblems.

Discussion: Discuss various farm machinery using the public roads (tractors and implements, combines, etc.). Discuss the shape, size, and color of an SMV emblem. Discuss where the SMV emblem should be located on a tractor or farm implement (center; back of vehicle; high enough for car lights to shine directly onto emblem; from 2 to 10 feet off the road surface). The SMV emblem should be securely mounted with bolts so the surface is straight and perpendicular to the surface of the road.

QUESTION & ANSWER

Q: Why are SMV emblems necessary on farm machinery?

A: Due to the difference in speed, a slower vehicle such as a tractor, needs to be visible from a distance in order for a faster vehicle to slow down and avoid a collision. To facilitate this, machines that travel less than 25 miles per hour need to have slow moving vehicle emblems on the back to increase visibility. Not all states have SMV regulations while some have different speed limits, so check your state laws.

Q: When driving a vehicle on the road, what should the driver do when they come up behind a tractor with an SMV emblem?

A: Farm vehicles are allowed on the traveled portion of a highway. The orange and red triangle is a signal to all drivers to slow down and be cautious. When you see it, reduce your speed and maintain a safe following distance. Only pass when it is safe to do so. Some farm vehicles are long and wide and may turn at places that are not well marked, such as field entrances, so be prepared to stop.

Q: When are you most likely to come across tractors and other farm machinery while driving on rural roads?

A: Farm machinery is most likely to be on the road during planting and harvest but they may be on the road at any time during the year.

Q: What things prevent an SMV emblem from reflecting properly?

A: It is important that the emblems are clean and in good condition. As SMV emblems age, they lose their refl ective ability. Replace SMV emblems that are no longer reflective.

Q: What things can youth do to help keep the drivers of slow moving vehicles safe?

A: Notice when an SMV emblem becomes faded and loses its reflexivity. Ask an adult for help in replacing it with a new one. If the SMV emblem becomes dirty, wash it with soap and water. These actions can help prevent a machinery/vehicle collision. When riding in a vehicle, youth can inform the driver when they spot a slow moving vehicle on the roadway.

Q: Where is the slow moving vehicle (SMV) emblem placed on the tractor or implement? Which characteristics of an SMV emblem help to improve its visibility?

A: The SMV emblem is placed 2 to 10 feet above the road surface on the middle back of the tractor or implement. An SMV emblem must be highly reflective and clean. If not, other drivers sharing the road with the tractor cannot see the tractor early enough to slow down to prevent an accident.

Q: Why should SMVs NOT be used as driveway markers?

A: SMV emblems are intended for use on tractors and other farm machinery. If they are used in other situations to call attention to a specific area, their purpose of calling attention to a tractor is diminished.

Objective: Identify the importance of seatbelts on a tractor with a cab or ROPS.

Concept: Rollover protective structures (ROPS) provide a protective zone for the tractor’s driver. A seatbelt holds only the driver (not any other rider) within the protective zone that the ROPS provides. If a seatbelt is not worn, the driver can be thrown outside this zone if the tractor rolls or goes over rough surfaces.

Targeted Age: Upper elementary school students and above

Time: 30 minutes Materials:

Have the students draw faces on the egg shells using markers or crayons to represent people. They can name them, if desired. Place the drop cloth or plastic bag under a table where the demonstration will take place. Create a raised driving surface on a table with the plywood.

Place one egg on each seat of the tractors. Drive the tractors (one with ROPS and one without) from the raised end of the board holding the eggs in place until the tractor picks up momentum. Let go of the tractor and the egg. Notice what happens to the eggs (drivers) when the tractors roll off the table.

Repeat the demonstration. This time tape the egg securely in the tractor seat on both tractors (ROPS and no-ROPS). The tape represents a seatbelt. Roll the tractors again to build up momentum and release.

Attach another egg (extra rider) onto the fender of the ROPS tractor with tape. Drive the tractor off the table and see what happens.

Discussion: Look closely at both tractors. Have the students explain the differences they find between the two tractors. Discuss the size of a person that would be driving each tractor and if they would fit within the safety zone provided by the ROPS. Discuss where the person would land if the tractor rolls onto its side or backwards.

QUESTION & ANSWER

Q: Does anyone in the group know of someone who has experienced a tractor overturn?

A: Answers will vary. If a death has occurred, ask the person about the driver’s age, the type of tractor they were driving, and what they know about the situation. Be sensitive especially if the person was a family member. If the driver survived, ask the speaker to explain which safety precautions saved his/her life.

Q: What is meant by a safe protective zone on the tractor?

A: The safe zone on a tractor is the area where the driver sits within the ROPS or cab. The ROPS or cab has reinforced steel that protects the driver in case the tractor rolls onto its side or backwards.

Q: Why is a seatbelt important when driving a tractor with a ROPS or cab?

A: In the case of an overturn, the driver must be held in place within the safe protective zone. When a tractor begins to tilt the driver looses balance and is thrown from his/her seat. They could very easily land in a place where the tractor could roll and crush them. This can happen even when the tractor has a ROPS or cab. When the tractor rolls the driver can be thrown off , if a seatbelt is not worn.

Q: Are there times when a seatbelt should not be worn on a tractor?

A: Seatbelts were not installed on tractors built without ROPS or cabs. If an older tractor without a ROPS is being used, do not have seatbelts retrofitted on them. Since there is no safety zone for the tractor driver, there is no reason to keep the driver in his/her seat. If the tractor overturns, the driver may be pinned under the tractor. If a tractor has a foldable ROPS, the seatbelt should not be used when the ROPS is not being used. Store tractors with foldable ROPS in the up position.

Q: Is there any safe place for an extra rider on a tractor?

A: No, there is no safe place for an extra rider on a tractor. Riders inside the cab should be limited to those providing training or machine diagnostics. The instructional seat is not intended or designed for use by children.

Q: What can be done for older tractors that were manufactured without ROPS?

A: Tractors can be retrofitted with a ROPS. Contact your local implement dealer and ask about a ROPS for your specific model. There is a national program associated with retrofitting a tractor, call 877-ROPS-R4U for more details. The University of Kentucky has a list of phone numbers to get ROPS. Visit: http://warehouse.ca.uky.edu/rops/ropshome.asp

Objective: Demonstrate safe driving practices using toy tractors.

Concept: Driving a tractor on an incline or on uneven terrain increases the dangers associated with operation. This is often the case when tractors are in operation on the farm.

Tractors are very heavy. If they become unbalanced when operating on sloped surfaces, this heavy weight shifts and pulls the rest of the tractor with it, possibly turning the tractor over. The steepness of the slope influences how likely the tractor is to tip.

Front tractor weights affect the center of gravity and help to keep the wheels on the ground when driving on hills.

Targeted Age: Upper elementary school students and above

Time: 30 minutes

Materials:

Form two inclined driving surfaces with the plywood and risers. Place the flat surface at the top of the steep incline so the tractor can drive easily from the incline to the flat surface.

Allow the students to pass the tractors around and instruct them to pay attention to the weight distribution of each tractor. Drive each tractor up each slope and compare the weight distribution when driving up the steep and slight slopes. Turn the tractors around and back up each slope. When backing up a hill the drive wheels are at the top, making it less likely to tip over. Drive one tractor on the ridge between the flat surface and the steep slope; this represents driving with one wheel in a ditch. Observe and feel which way the tractor pulls.

Discussion: Look closely at both tractors. Have the students explain the differences between the two tractors (size, cab or ROPS, weight, SMV emblem, etc.). Discuss how each item relates to safety.

Study the angle of the slopes represented by the plywood surfaces. Estimate the diff erence in the angles of the two slopes. Explain how the steepness of the slope impacts the stability and center of gravity of the tractor.

Discuss places on the farm where tractors have to drive on sloped surfaces (ditches, hills, etc.) and what the tractor may be doing (mowing, driving on hilly roads, etc.). Discuss the characteristics of the tractor that make it safer when driving on slopes (weights and ROPS).

QUESTION & ANSWER

Q: Why is driving up a steep slope backwards a safe option?

A: By turning the tractor around the weight is redistributed. The back tires, especially if they are dual tires, are very heavy and are used for traction. When driving forwards up a hill, the front of the tractor may come off the ground, causing the tractor to tip over backwards. Weight is often added to the front of the tractor to counter balance the weight of the back tires. When driving backwards, you are moving the heaviest part of the vehicle first and therefore less likely to tip.

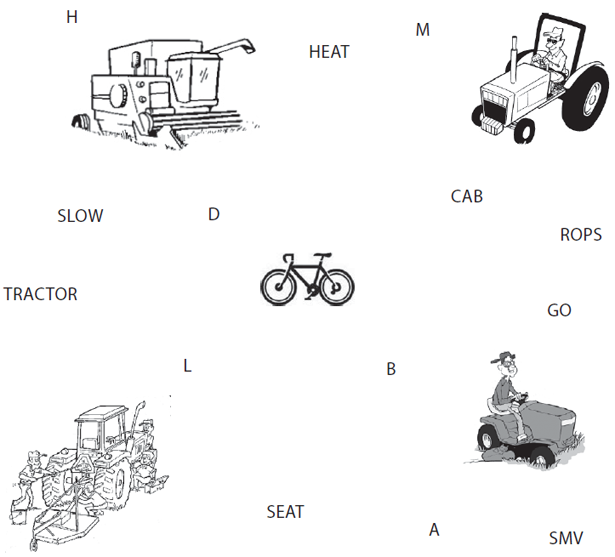

Objectives:

Concept: Tractors are used extensively on most farms. These tractors range from small lawn tractors to large, powerful, highly specialized vehicles. All machines can be hazardous when they are operated improperly.

Hazard examples include:

Targeted Age: Upper elementary school students and above

Materials:

Place the dowel stick into the hot dog lengthwise. Start the fan, motor, or bicycle wheel spinning. Holding the dowel close to the end opposite the hot dog, place the hot dog end into the blade. The stick represents a bone and the hot dog represents flesh. The motor or wheel represents the tractor motor.

Discussion:

Each year, people are hurt when they tempt fate by working around motors that are not shut off or shielded properly. Ask the students to list items on a tractor that can move quickly (motors, fan blades, auger, PTOs).

QUESTION & ANSWER

Q: Where are fast moving parts found on the tractor?

A: The tractor motor has fan blades and belts that move quickly. Implements that are powered by the tractor often have fast moving objects. Augers, PTOs, and fans all fall into this category.

Q: What things can you do to prevent injuries from moving parts on a tractor?

A: Install shields over moving parts to prevent a person from getting caught. If a shield becomes defective due to age, it should be replaced.

Q: Which body parts are most likely to be hurt by moving parts on the tractor?

A: Fingers, feet, and hair are body parts most often caught in moving mechanisms.

Q: What can youth do to prevent injuries from powerful, moving parts?

A: If you see a missing shield, tell an adult so they can repair it.

Materials:

Match up the shapes with the classes of fire extinguishers. Using a multi-class fi re extinguisher, practice extinguishing a fi re using the Pull, Aim, Squeeze, and Sweep system. Have each student practice putting out an imaginery fire to perfect the PASS system.

NOTE: If a professionally trained fireman is present, build a small fi re in a self-contained trough and have the students use the fire extinguisher on a real fire.

Discussion: There are four types or classes of fire extinguishers, each of which puts out a specific type of fire. Newer fire extinguishers use a picture labeling system to show which type of fire the extinguisher will put out.

QUESTION & ANSWER

Q: What could cause a fire to start around the tractor?

A: Flammable liquid fuel is present because it’s used to power the motor. Harvesting dried plant crops, such as corn, beans, and hay can also produce a combustible fuel source.

Q: Which fire extinguisher would be the best to carry in the tractor?

A: There is no way to know how a fire might start on a tractor, so multi-class rated fire extinguishers are preferable.

Q: What is the best procedure to make sure a fire is put out?

A: PASS will help you remember the proper way to use a fire extinguisher:

Q: What should you do if you notice that a fire has started around a tractor?

A: Tell an adult about the fire. Remind parents and adults to make sure fire extinguishers are working properly and they know how to use them.

Materials:

Draw a face on the melon to represent a person’s head. Using the ladder, climb to the top of a tractor cab, approximately 10 feet. Drop the melon onto the plastic tarp on the ground below.

Discussion: Tractors and other farm machinery are tall. If farm equipment is available, estimate how many feet off the ground the driver’s seat or the platform are located. Compare this to the number of stories or windows in a building. Talk about an instance where people have accidentally fallen from these heights.

QUESTION & ANSWER

Q: How tall is a large tractor?

A: Large tractors can be up to 10 feet tall. Combines can be even taller.

Q: What part of your body is the most vulnerable during a fall?

A: The head is the most vulnerable. If your skull is broken or cracked, the brain could be damaged. While other bones and muscles can heal, the brain is not easily repaired.

Q: How can you prevent falls from tractors and farm machinery?

A: Ladders and platforms used to access the driver’s seat need to be kept free of slippery substances such as water, ice, grease, and manure. When using the ladder and platform, be sure to use the hand rails. Always face the tractor when mounting and dismounting, using the hand rails. Dismounting facing forward may result in falling face first.

Materials:

Stuff the coveralls with straw or paper to represent a person’s body. An inflated balloon or Nerf ball can be attached to the coveralls to represent the human head. Make sure the PTO is in proper working condition.

Attach the stuffed “dummy” to the PTO shaft with a hidden string. (If you hold the dummy over the rotating PTO shaft it might not catch.) Do not allow youth to stand close to this demonstration. Create barriers using colored hazard tape to keep youth at least 10 feet from the demonstration. Have several adults present to make sure youth stay behind the barrier. Start the tractor and PTO. The dummy will begin spinning around the shaft. Stuffing may fly out of the Tyvek suit.

Discussion: Discuss why PTOs are used and the dangers that exist when the shaft is spinning. Discuss why shields are used to cover the PTO shaft and ways to identify when a shield needs replacing (cracked, bent, or missing areas, and protruding points).

QUESTION & ANSWER

Q: What type of implements are powered by a running PTO?

A: Manure spreaders, augers, mowers, choppers, balors, and grinders, etc.

Q: How does the PTO transfer power from the tractor to the implement?

A: The tractor spins a metal shaft around very fast. This speeding circular action causes the mechanisms within the implement to rotate.

Q: How fast does a PTO shaft spin while it is working?

A: Depending on the power of the PTO, it could spin at 540 RPM or 1,000 RPMs (revolutions per minute). At 540 RPM the shaft is rotating 9 times per second. Our normal reaction time is 3/4 of a second - that means anything caught would wrap 6 times around the shaft before we realize it. The speed is dependent upon the power of the tractor and the implement that it is running.

Materials:

With the nozzle closed, fill the hose with water. Turn the water off at the source. Let the hose set in the sun for several hours. When the hose feels hot, open the nozzle and notice the force of the water. After the initial hot water in the hose is released and the pressure is relieved, the water flow should subside.

Discussion: Tractor hydraulics are used to move or lift heavy items. The built up pressure is the force that causes the action. The term “hydraulic” refers to fluids under pressure. In the demonstration, the water is the fluid but since water becomes steam at 212 degrees Fahrenheit, it can not be used within a hydraulic system because it cannot build up enough pressure.

QUESTION & ANSWER

Q: What fluid is used in a tractor’s hydraulic system?

A: Oil is used. Oil has a much higher boiling point than water.

Q: How can tractor hydraulics be dangerous to a tractor operator?

A: The oil is under very high pressure, up to 3000 pounds per square inch. A leak in the hose could force oil under your skin and act like a poison. The heat generated by the pressure can also burn the operator.

Q: What precautions should be taken when using hydraulic components?

A: Wear gloves and safety glasses when working with a hydraulic system.

Objective: Determine the relationship between a tractor’s center of gravity, weight distribution, and overturn potential.

Concept: Tractors are used extensively on the farm. Front end loaders, hay forks, and scoops allow farmers to lift very heavy items. When lifting heavy objects, the center of gravity shifts on the machine. This shift can cause tractors to overturn. Gravity is the pulling force between two objects due to their masses. Center of gravity (COG) is the balance point of objects.

Targeted Age: Middle school students

Materials:

Make several copies of the tractor, loader bucket, and hay fork for each student (see pages 36-37). Instruct each student to glue the pictures onto the cardboard. Do the same thing with the large, round hay bales. Cut out the cardboard objects.

Attach a tack to both ends of a piece of string. Tack the top of the string into a bulletin board. Attach the second tack into the cardboard cut out of the tractor and allow it to pivot freely. When it comes to a rest, draw a line on the cardboard under the string.

Remove the tack from the cardboard and place it in a different location. Repeat. All the lines should meet at the same point. The meeting point marks the object’s center of gravity. To expand on this concept, ask the kids to balance the cardboard cut out on the flat pencil eraser. It will only balance at the center of gravity. Repeat the demonstration using the remaining attachments.

Use tape to attach the loader bucket or a hay fork to the tractor in various positions. Tape a bale to the loader arm and identify the new center of gravity using the ruler, string, and tacks as before.

Compare the intersecting points. Notice the center of gravity changes as the weight distribution changes. Discuss the extra weight of the object being moved and how this alters the center of gravity.

Allow the students to try various weights and various height positions to determine the change in the center of gravity.

Refer to Drive Head over Wheels activity on page 29. Using a tractor with a front end loader, compare various objects in the loader and bucket height to identify when the tractor is most stable and when it is most likely to tip over.

Discussion: Discuss the relationship between the center of gravity and overturns.

QUESTION & ANSWER

Q: When is a tractor most likely to overturn?

A: A tractor is very large and heavy. If the weight of the tractor is off -balance and starts to tip, it is difficult to stop the roll. Very similar to a snow ball picking up speed as it rolls down a hill, a tractor is hard to stop once it becomes off balance. Tractors can become off -balance when they are operated on hills, ditches, or rough surfaces.

Q: When using a front end loader on a tractor, what is the safest possition for the bucket?

A: Always keep the bucket low when possible.

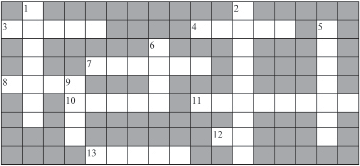

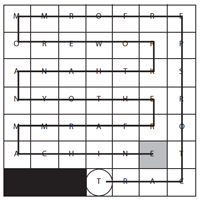

ACROSS

3. Sign that can be affixed to warn people about the dangers of extra riders

4. Young person

7. What you should do if someone asks you to ride on a tractor

8. Tractor operator’s line of sight

10. Responsible person; older than a child or youth

11. Tragic result of riding on a tractor

12. Safe response when offered a ride on a tractor

13. Sound that can hurt your ears

DOWN

1. Sense that can be damaged by exposure to high decibel noises

2. Shaking caused by tractor movement

5. Large, commonly used farm machine

6. Dirt in the air

9. Safe alternative mode of transportation; do this instead of riding on a tractor

Targeted Age: Upper elementary school students and above

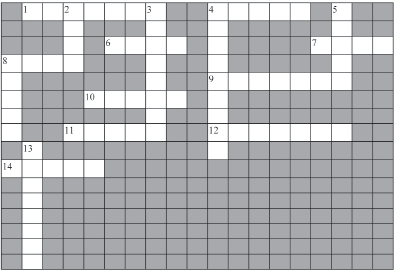

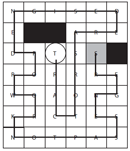

ACROSS

1. Metal implement hitch located on the back of a tractor

4. Sharp slope

6. Raised mound of earth

7. Backside of the tractor

8. Direction a tractor might tip if mowing a ditch

9. Wear a seatbelt on a ROPS tractor to protect you from being __ in an overturn

10. Weighs a lot

11. Implement pulled behind a tractor; used for cutting

12. Large, commonly used farm machine

14. End of life

DOWN

2. Rod between two wheels

3. This can occur when a tractor becomes unbalanced

4. Resistance to tipping

5. Rate at which a vehicle is traveling

8. Steepness of a hill

13. Safety mechanism worn around waist to protect driver

Targeted Age: Upper elementary school students and above

ACROSS

1. Far from the ground

7. Support to hold on to

8. Lose your balance

9. Large, commonly used farm machine

13. Barrier that may impede tractor movement

15. Animal waste; slippery substance

DOWN

2. Harm the body

3. Always wear __-slip shoes when climbing onto a tractor

4. Mechanism pulled behind a tractor

5. Dangerous way to dismount a tractor

6. Not slow

10. Using a ladder to go up

11. High surface to stand on

12. Frozen water

14. Hard body parts that can be broken

Targeted Age: Upper elementary school students and above

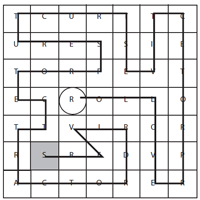

ACROSS

3. Type of hair or jewelry that can become caught in a PTO

4. Become twisted

6. Walk ___ the tractor when the PTO is running

7. Implement used to cut grass

8. Never ___ over an operating PTO

10. PTOs rotate at a high ___

11. Result of getting hair caught in a PTO

12. Mechanism pulled behind a tractor

13. Spin around

DOWN

1. Wear ___ fitting clothing when working with a PTO

2. Wound

3. Shaft of a PTO

5. Large, commonly used farm machine

6. Corkscrew-like mechanism that moves grain

7. ___ spreader

9. How should long hair be worn to prevent it from getting caught in a PTO?

10. PTO shaft cover

Targeted Age: Upper elementary school students and above

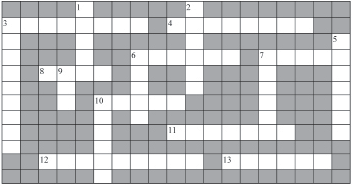

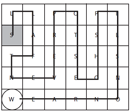

ACROSS

2. Not going fast

6. Not slow

7. Curve in the road

8. Raised mound of earth

9. Small truck

11. Turn over

12. Passenger vehicle

13. Abbreviation for slow moving vehicle

14. Large, commonly used farm machine

15. Trench along the side of the road

DOWN

1. Opposite of small

2. Sharply sloped

3. Lane used to exit farmstead

4. Surface of many rural roads

5. Farm animals that might wander on to the road

10. Mechanism pulled behind a tractor

Targeted Age: Upper elementary school students and above

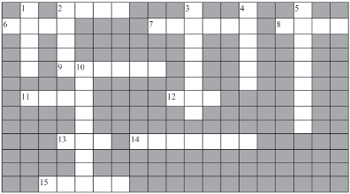

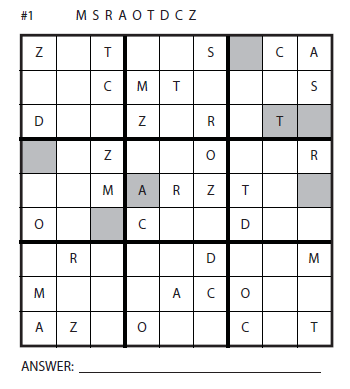

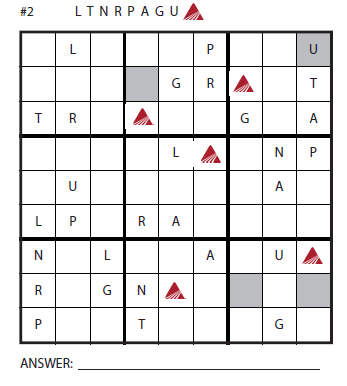

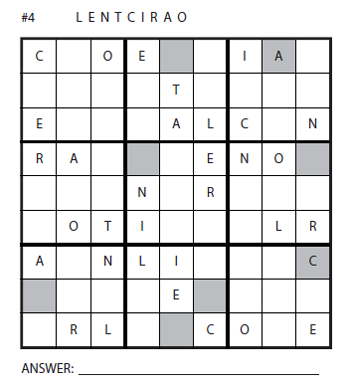

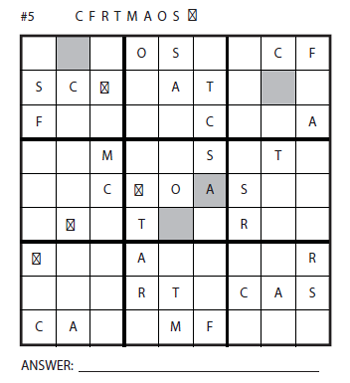

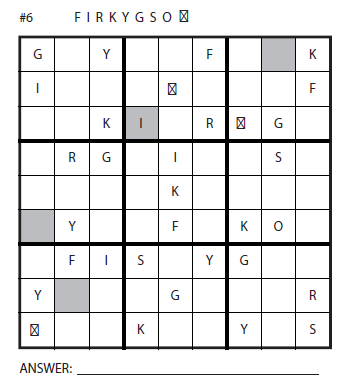

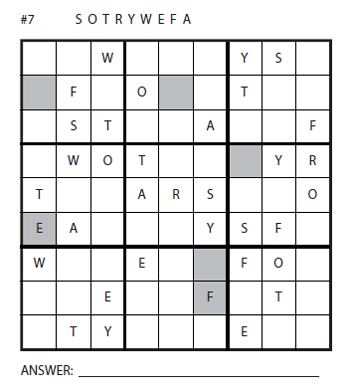

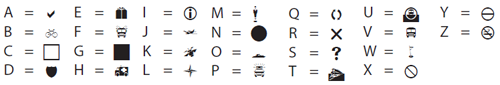

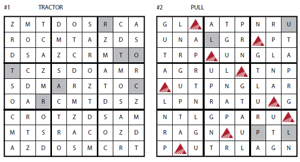

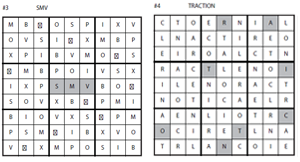

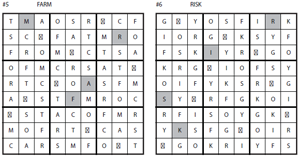

To solve Sudoku puzzles, place a diff erent letter or symbol in each row across, each column, and each small 9-box square. No letter or symbol may appear more than once in any row, column, or small 9-box square. Rearrange the letters in the shaded boxes to form a word associated with tractors.

Targeted Age: All ages

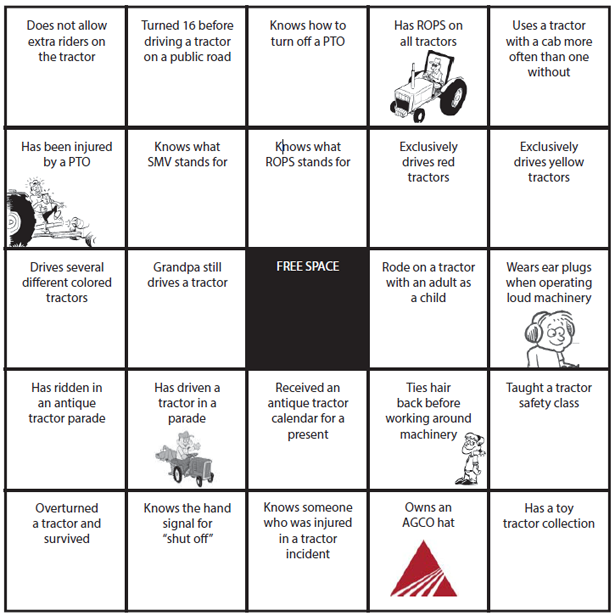

Make a photocopy for each participant. With a pencil in hand, find someone within the group that can answer each statement. Each person can only sign one space per page. The first person to get signatures on five boxes in a row wins!

Supplemental Activity: Identify which statements are unsafe. Why are they insafe? Ask them to give additional information about the experience, situation, or item described in each statement. How does each answer influence the safety of the individual involved? Which items do not impact safety?

Targeted Age: Elementary school students

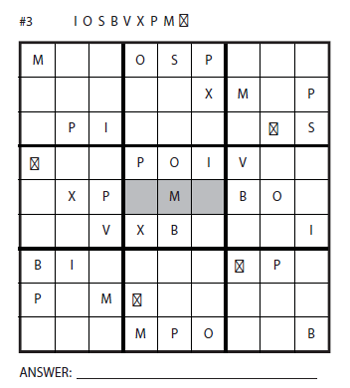

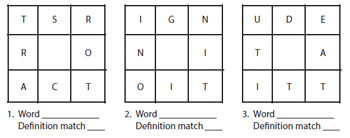

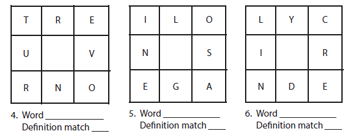

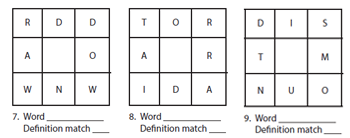

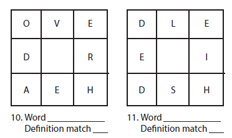

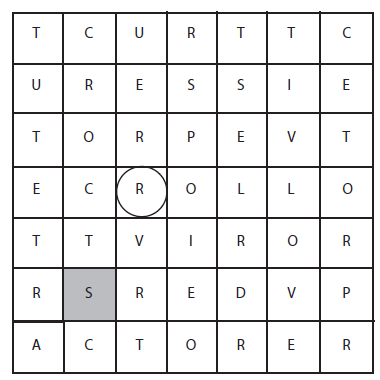

Find the tractor related, eight-letter-word in each square. Words can be spelled forwards or backwards and can start in any box. Match the word with the correct definition.

A. Get down off the tractor

B. When a tractor turns over on itself

C. Cooling device

D. Large, commonly used farm machines

E. Opposite of upwards

F. Round tube

G. Electrical system that starts the engine

H. A state of mind

I. Fuel for combustible engine

J. Electrical lines that should be avoided when using a front end loader

K. Covered PTO shaft

Supplemental Activity:

Each word relates to operating a tractor safely. After you unscramble the words, try using them in a sentence.

Targeted Age: Middle school students

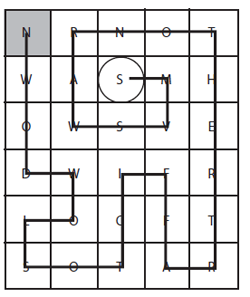

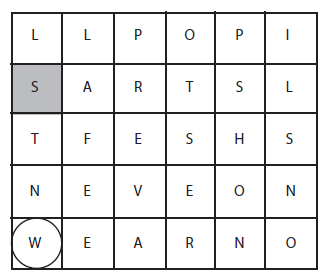

Each box contains a message about staying safe around tractors. Decode the message by drawing one continuous line, reading the words in any direction, horizontally, vertically and/or diagonally. Each letter is only used once. Start at the circled letter and end at the shaded square. Hint: Your lines will never cross.

EXAMPLE

Hint: Reflective triangles help drivers see tractors while on the road.

Answer: SMVs warn other traffic to slow down

Hint: This large piece of equipment is on almost every farm.

Supplemental Activity: Each statement listed above talks about the safe use of tractors on the farm. Have each student write an additional statement, and using graph paper, create their own puzzle for another person to solve.

Targeted Age: Middle school students

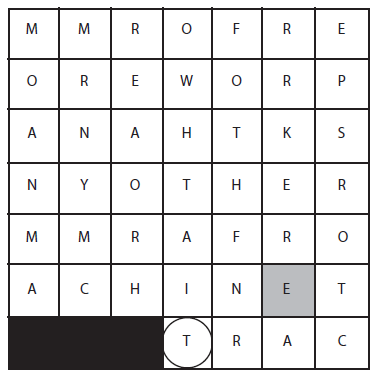

Each box contains a message about staying safe around tractors. Decode the message by drawing one continuous line, reading the words in any direction, horizontally, vertically and/or diagonally. Each letter is only used once. Start at the circled letter and end at the shaded square. Hint: Your lines will never cross.

Hint: Dangerous place to be on a tractor.

Hint: This device helps protect a tractor operator.

Hint: Type of footwear to use while on a tractor.

Targeted Age: Middle school students

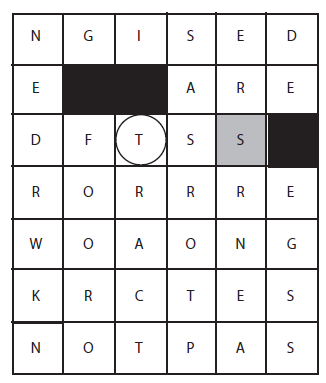

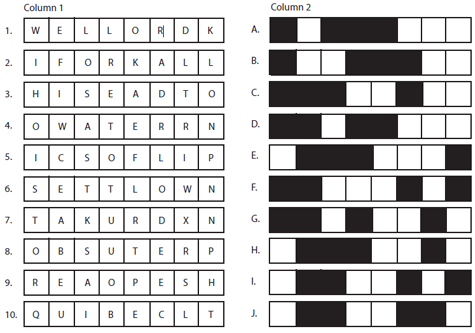

There are tractor-related, 4-letter words hidden amongst the letters in Column 1. Each word shows the letters in the correct order but other letters have been added. Find the hidden word then draw a line to match the word to the blank boxes in the second column.

EXAMPLE

Supplemental Activity: Each of the words listed in the boxes are related to using a tractor. After participants identify the words, conduct a group activity by having each child use the words correctly in a sentence to show he or she knows the meaning of the words. See who can form a complete sentence using the most words from the puzzle. Example: Slip-resistant shoes should be worn to prevent falls on stairs. ROPS and seat belts can prevent injuries.

Targeted Age: Middle school students

Start with the three words CARRY NO PASSENGERS and follow the directions to complete the thought.

| CARRY NO PASSENGERS | |

| Remove the first letter of the last word | _ _ _ _ _ -_ _- _ _ _ _ _ _ _ _ _ |

| Remove all double letters | _ _ _ -_ _-_ _ _ _ _ _ _ |

| Substitute ‘s’ for ‘c’ | _ _ _-_ _ -_ _ _ _ _ _ _ |

| Add ‘rid’ in front of the second ‘a’ | _ _ _ - _ _-_ _ _ _ _ _ _ _ _ _ |

| Duplicate the 5th letter | _ _ _-_ _ _-_ _ _ _ _ _ _ _ _ _ |

| Add a space and ‘t’ between the double letters | _ _ _-_ _-_ _-_ _ _ _ _ _ _ _ _ _ |

| Remove the 2 vowels right together | _ _ _-_ _ -_ _-_ _ _ _ _ _ _ _ |

| Remove ‘ng’ | _ _ _-_ _-_ _ - _ _ _ _ _ _ |

Supplemental Activity: Identify two short phrases that are related to tractor safety and each other, for example: “A rollover protective structure” and “Could save a life.” Write instructions to change the letters in the first phrase to end up with the letters and spacing for the second phrase. See who can change the phrase in the least number of steps.

Targeted Age: Early elementary school students