Various ways are used to prevent insects from attacking stored products. Once insects get into a stored product, however, few practical solutions are available for getting rid of them. Small amounts of products can be frozen, or heated, to kill the insects. Large quantities need to be fumigated. This publication presents information about using phosphine fumigants to control insect infestations in stored agricultural commodities.

Phosphine fumigants are sold in solid form, either as aluminum phosphide or magnesium phos- phide. This publication focuses on aluminum phosphide that is sold under various brand names including Phostoxin, Phosfume, and Weevilcide. Aluminum phosphide can be used to eliminate insect infestations in a variety of commodities, including animal feed and feed ingredients, corn, cottonseed, grass seed, millet, oats, peanuts, pecans, popcorn, rye, sorghum, soybeans, triticale, and wheat. They can also be used for a variety of processed foods as long as the residue dust does not come in direct contact with the product. They can be used on some nonfood commodities including straw and hay, cotton, feathers, tobacco, dried plants and flowers, and seeds. The fumigant label contains a complete list of commodities that can be fumigated. Phosphine fumigants can be used in a variety of structures including grain bins and silos, rail cars, warehouses, and flat storage structures.

When the solid fumigant is exposed to water vapor in the air, a chemical reaction occurs releasing phosphine gas (hydrogen phosphide) and heat:

Aluminum phosphide + Water = Phosphine gas + Aluminum hydroxide + heat

AlP + 3H2O = PH3 + Al(OH)3 + heat

The breakdown of the solid fumigant starts slowly, gradually accelerates, and then tapers off. When the chemical reaction has finished, all that is left is a non- hazardous gray powder consisting of aluminum hydroxide and other inert materials.

Phosphine gas is highly toxic, reactive, and potentially explosive. Because of the dangers associated with their use, phosphine fumi- gants are restricted-use pesticides that can be used only by trained and certified applicators in accordance with label instructions. Farmers who have a private applicator’s license can apply phosphine fumigants on their farms.

An effective fumigation requires that the phosphine gas be held in the infested structure long enough to kill the target pests. After fumigation, the gas must be vented to the legal level for human exposure. These requirements are constant regardless of the structure involved; however, different types of structures may require different application procedures and safety considerations.

When you purchase a phos- phine fumigant, be sure to ask for the applicator’s manual, which is legally part of the fumigant label. The manual contains information needed to perform a safe, effective, and legal fumigation procedure. Read and follow all instructions on the container label and in the applicator’s manual. Remember that the label, including the applicator's manual, is the law. This publication is not a substitute for the applicator's manual. It is meant to be an overview of the process of fumigation.

Why should I read the applicator's manual?

What is a fumigation management plan?

This is a written plan that sum- marizes all the steps that will be taken before, during, and after the fumigation. It makes sure that the fumigant is applied effectively and safely by forcing you to think about all the steps beforehand. The applicator’s manual explains what has to be in the plan: you must document who, what, when, where, how, and why. For example, who should be told about the fumigation because they might be accidentally exposed to phosphine gas during the fumiga- tion, or who should be notified in case of emergency. Include the phone numbers of the nearest fire department, police department, hospital, and your physician. Also, who will conduct the fumigation? What commodity will be fumi- gated? What type of structure will be fumigated? Can it be sealed? If not, it shouldn’t be fumigated. When will you begin the fumiga- tion, and when will you end the fumigation? When will it be safe to use the commodity? Describe the characteristics of the site, in- cluding a sketch. Indicate places where people might be acciden- tally exposed to phosphine gas. Think about where phosphine gas can escape and where you need to seal potential leaks. How will the structure be sealed? How will accidental exposure be pre- vented? How will you monitor gas concentrations? How will you apply the aluminum phosphide pellets or tablets? How will you aerate the structure? Why was the fumigation necessary?

Do I have to prepare a fumigation management plan?

Yes, unless you have some old product that came with the old (pre-2004) label. The plan needs to be kept on file for at least 2 years.

Why should I seal the structure?

How do I seal the structure?

Various materials are available, including plastic (4 mil or thicker is best), duct tape, explanding foam, and caulk. If you think you will need to fumigate, seal all cracks and crevices before you load the commodity into the structure. Every step you take to seal potential leaks will allow the gas to be distributed throughout the enclosure will improve effectiveness.

Should I use tablets or pellets?

Aluminum phosphide is packaged as tablets about 5/8 inch in diameter, as pellets about 3/8 inch in diameter, or as granules in a sachet or small, porous bag. Tablets release about five times more phosphine gas than pellets release. At high temperatures, it may be safer to use tablets because they break down slower than pellets. If you are fumigating a raw agricultural commodity, you ca use tablets or pellets, without removing the residue. For processed commodities, prepacs, ropes, or blankets, keep the residue within the packaging so it can be removed after the fumigation.

How much aluminum phosphide do I need?

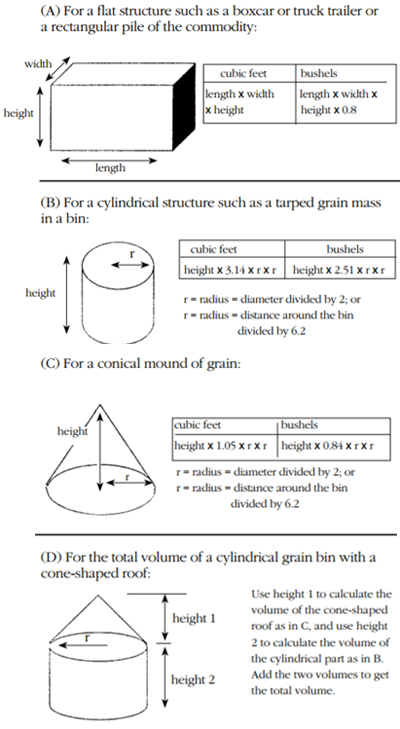

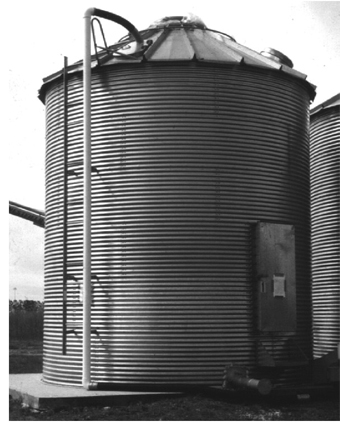

The applicators manual recommends different amounts for different structures. The maximum dose is 900 pellets or 180 tablets per thousand bushels (725 pellets or 145 tablets per 1,000 cubic feet). Since phosphine gas diffuses to an equal concentration within the structure containing it, volume (cubic footage, Figure 1) is usually a better way to calculate dosage than the number of bushels. For example, if you have 2,000 bushels of wheat in a 6,000-bushel bin, calculate the dose for 6,000 bushels because the gas will spread throughout the structure. An exception would be if you placed a plastic tarp over the top of the grain to keep the gas within the commodity, then you would calculate the dose for 2,000 bushels. Dosage depends not only on the volume of space to be fumigated but on the temperature, the commodity, the moisture content of the commodity, and how well the structure is sealed.

How long does it take to fumigate?

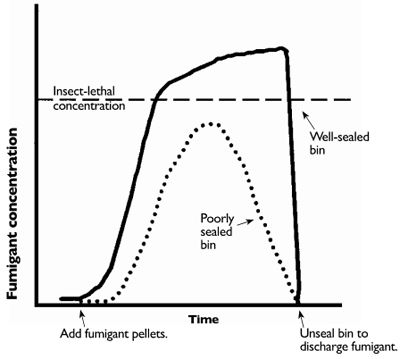

Do not rush the fumigation. You must give the gas time to build up to the concentration needed to kill insects (Figure 2). Respiration rates of insects are much slower than those of humans, especially in cooler tem- peratures. Only minutes of expo- sure of a given concentration of phosphine can be very dangerous to humans while the same con- centration may take days to kill insects. Phosphine gas concentra- tion also depends on temperature. It takes at least 2 days for the pel- lets to break down when the tem- perature in the structure is above 68 degrees F. It takes about a day longer if you are using tablets. The cooler it is, the longer it takes (Table 1). Then, it can take up to 2 days to aerate the product after the fumigation. Many professional fumigators like to see gas concen- trations of 200 to 300 parts per million for a minimum of 3 days. Not allowing enough exposure time can be a waste of money, but, more importantly, it can be very dangerous because the solid fumigant may not have completely broken down when the commod- ity is moved and people are then exposed. Partially spent fumigant, called greendust, will continue to give off gas and may create a sig- nificant hazard to anyone near the commodity. Special procedures are needed to dispose of green- dust. They are discussed in detail in the applicator's manual.

How do I apply the fumigant?

The applicator’s manual pro- vides tips for how to fumigate farm bins, flat storages, rail cars and other transport vehicles, vertical storages, mills, food processing plants and warehouses, tarped commodities, barges, small sealable structures, bee- hives, and in-transit ship holds. This includes where and how to place the fumigant. Too much aluminum phosphide in any one spot can lead to fires and explosions.

How long do I have to apply the fumigant in the grain bin (peanut warehouse, etc.)?

It depends on the temperature, the moisture in the air, and the volume of air in the headspace. The only way to be sure is to have an air monitoring device (see below) to make sure the gas concentrations are below safe levels. It is most dangerous to apply the fumigant on a hot, humid day. In an experiment on a hot day in South Georgia, six pellets left confined in a 30-gallon garbage can generated 50 ppm of gas in 5 minutes and 200 parts per million in 40 minutes.

Table 1. Temperature and Minimum Length of Exposure Time Needed to Fumigate With Aluminum Phosphide* |

||

|---|---|---|

| Temperature | Pellets (0.6 g) | Tablets (3 g) |

| 40°F or below | Do not fumigate | Do not fumigate |

| 41 to 52°F | 8 days | 10 days |

| 54 to 59°F | 4 days | 5 days |

| 60 to 68°F | 3 days | 4 days |

| above 68°F | 2 days | 3 days |

*Allow longer exposure periods for taller storage structures. A rule of thumb is to add 24 hours for every 10 feet of vertical distance in tall structures such as grain silos. Commodities with a low moisture content, such as grain with less than 10% moisture, should be given a longer exposure period—24 hours for each 0.5% under 10% moisture. Adapted from Phostoxin Applicator’s Manual, DeGesch America, Inc. |

||

I can smell the gas, can't I, and know when to get out?

No. Phosphine gas has no odor. The garlicky smell is the result of a different chemical reaction. Although it is an exposure indicator, you can’t always depend on the smell.

During a fumigation procedure, observe the following safety rules in addition to the rules specifically relating to fumigation.

Phosphine fumigants are valuable tools as long as they are used properly. Read and follow all instructions on the label, including the applicator’s manual to ensure a safe and effective fumigation.

Store all containers of fumigant under lock and key, and keep a careful inventory so each con- tainer and package is accounted for. If you discover that any fumigant has been stolen, you are required to report the theft imme- diately to your local law enforcement authorities. Make sure the storage area is properly placarded as a pesticide storage area. The applicator's manual specifies what must be on the placards for an area where phosphine fumigants will be stored. Never store fumigants inside a home or in any structure where humans or animals live. Just-in-time delivery of exactly the right amount of fumigant is the safest practice.

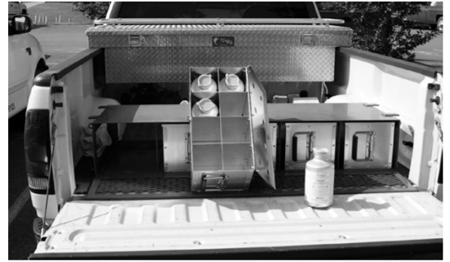

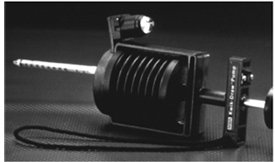

If you have to transport fumigants, keep the container(s) locked in a metal box in your truck bed. If you transport large quantities on a regular basis, you may want to consider a security system like the one in Figure 3. The applicator’s manual lists the hazards associated with transporting aluminum phosphide. Be aware of these hazards and have a list of them with you in the truck. Your truck will need to display a placard providing information about aluminum phosphide. If you are carrying less than 46 pounds of fumigant, you may be eligible for a placarding exemption, such as exemption DOT E 11329 (http://hazmat.dot.gov).

Make sure all employess know about the fumigation and are aware of potential safety hazards and emergency procedures. Make a list of the telephone numbers and addresses of the nearest fire department, rescue squad, hospital emergency room, and police department, and notify each agency of the fumigation ahead of time. Include on the list the names and telephone numbers of all appropriate personnel in charge. Provide each agency with a copy of your fumigation management plan and any other information needed in case of an emergency. This information should include the Material Safety Data Sheet (MSDS) for the phosphine fumigant used and a copy of the label, including the applicator's manual. There may be local requirements in addition to those in the applicator's manual. As you work your way through notifying the above agencies, you may learn of additional requirements. Accidents involving aluminum phosphide are rare - but in case the worst happens, a well-informed emergency response team would have a greater chance of saving your life than one that has not been informed about the hazards of aluminum phosphide.

A certified applicator is someone who has passed a state exam. Individuals receiving specific instructions in documented training sessions are classified as trained applicators. One certified applicator and another trained person are the minimum personnel required when aluminum phosphide is applied. Two trained people can legally make the application, as long as they are under the direct supervision of the certified applicator. All should carry some form of communication device, such as a radio, a walkie-talkie, or a cellular phone. See the applicator’s manual for requirements after the application.

You cannot follow label instructions without knowledge of the phosphine gas concentration during the fumigation process. One possible exception would be an isolated farm bin location on private property (see sections 10.3, 18.1, and 22.1 in the applicator’s manual). The label requires that you keep a log showing phosphine gas concentration at key locations surrounding the structure. The type of respiratory equipment used depends on the gas concentration. Furthermore, it makes sense to monitor the gas inside the structure (using extension hose from a safe outside location) to make sure an insect-lethal concentration of gas is present. Information about air-monitoring equipment is available from fumigant manufacturers and distributors. Safety equipment catalogs also provide valuable information and help in choosing the appropriate equipment. Two methods are commonly used to monitor the concentration of phosphine gas in the air. One method is using a hand-held continuous exposure meter with a digital display (Figure 4). This meter may be able to monitor gases other than phosphine.

If you will be applying the fumigant from within the structure, you must have some form of respiratory protection on site to follow label instructions.Use approved respiratory protection when the gas concentration is above the permissible exposure level of 0.3 ppm (as an 8-hour time-weighted average) or 1.0 ppm (15-minute short-term exposure limit).

All respiratory protection equipment must be models approved by the National Institute for Occupational Safety and Health/Mine Safety and Health Administration. Half-mask, dual cartridge respirators used for many pesticides and organic vapors are not suitable for use wiht phosphine gas. A full-face canister gas mask (Figure 6) can be used at gas concentrations from 0.3 ppm to 15 ppm (for example, NIOSH/MSHA prefix TC-14G). Be sure to use canisters designed to filter out phosphine gas. These canisters are typically color-coded olive green with an orange stripe. If the concentration is above 15 ppm or if the phosphine gas concentration is unknown, use a self-contained breathing apparatus (SCBA).

The gas mask or self-contained breathing apparatus must fit the face properly. Any gaps that allow in unfiltered air will make the respiratory protection useless. Facial hair can interfere with the proper fit of a mask. A canister gas mask or self-contained breathing apparatus must be available on site when phosphine fumigant is applied from inside any enclosure. If air-monitoring equipment is not available on a farm, an approved canister gas mask must be worn during an application from within the structure.

Wear dry cotton gloves and body-covering clothing while applying the fumigant, and after fumigating, aerate the gloves and clothing before laundering them. Wash hands thoroughly after using phosphine fumigants. Keep all containers tightly closed until it is time to apply the fumigant. Then it is a good idea to open the fumigant containers in the open air or near an exhaust. fan. Otherwise, the accumulated gas within the canisters may provide an alarmingly high concentration of gas in the breathing zone during the fumigation. To open the container, invert it several times, point it away from the face and body, and slowly loosen the cap.Do not open the containers in a flammable atmosphere. Dispose of empty containers according to label instructions. Do not allow the aluminum phosphide to contact liquid water, and do not leave aluminum phosphide pellets or tablets in piles because doing so interferes with the proper release of the phosphine gas. It also increases the risk of explosion or fire should the pile be suddenly exposed to water. Fire or explosion can occur if phosphine gas concentration exceeds 1.8 percent. The gas is corrosive to copper, brass, and precious metals, so electric and electronic gear should be protected from exposure or removed.

Post warning placards on all entrances to structures under fumigation. Placards must be weather proof. They can be handwritten, but they must include specific information. See the applicator’s manual for details. Remove placards only when the gas concentration is 0.3 ppm phosphine gas or less. Make the structure under fumigation as secure as possible by putting locks on the entry points. If there is a fence surrounding the structure, make sure that the gate is locked. A security guard may be required under extremely sensitive conditions, such as in the middle of a town.

Although phosphine gas tends to penetrate deep into large volumes of stored commodities, its ability to evenly distribute itself does have limits. The following are some factors that would inhibit even distribution:

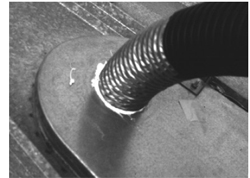

When any of these conditions exists, insects may be killed in one section of the enclosure and not in another. One way to deal with the problem of uneven distribution is to use a closed-loop fumigation system (Figures 7 through 9), which improves the distribution of phosphine gas within an enclosure. It involves the use of a tubing system and a blower to continuously recirculate the phosphine gas during the fumigation period. The system can be designed in a number of ways, but, for most situations, using 4-to 6-inch-diameter PVC pipe and flexible, solid drain tile is an inexpensive way to move gas from one point to another along the outside of the structure. The system should be designed to draw the gas from the head-space of the bin and reintroduce it under the false floor. Place a blower at a convenient point in the system. Usually a 0.25- to 1.0- horsepower motor is adequate. Proper sealing of the structure is even more critical with closed- loop fumigation since recirculation may speed up the escape of gas. Make sure all joints between sections of tubing and all entry and exit points are well sealed with duct tape, caulking, or other means. Place all tubing away from high-traffic areas, and protect it to prevent accidental damage. Test the system for leaks before applying aluminum phosphide.

Closed-loop fumigation systems are usually not necessary in small (less than 5,000 bu) tightly sealed bins. Advantages of closed-loop systems increase with the size of the bin since even distribution of the fumigant becomes more important. Closed-loop systems eliminate the need for labor- intensive and potentially dangerous probing operations or for moving grain from a full bin to an empty bin for the sole purpose of fumigation. Closed-loop systems can be safer than probing operations because the fumigant can be applied to the top of the grain so workers are not required to be inside the structure as long. Gas recirculation can reduce exposure time to as little as half the time required for some fumigations. Although there is an initial cost for a recirculation system, increased fumigant efficiency and lower dosages will usually pay for these costs in 1 to 4 years, depending on the size of the system and the frequency of fumigation.

Ocean-going vessels can be fumigated with phosphine fumigant in transit, as can rail cars and containers, trucks, vans, and other transport vehicles shipped piggyback by rail. However, it is not legal to fumigate trucks, trailers, containers, vans, or other vehicles as they are being moved on public roads or highways. The fumigation must be completed and the placard removed following aeration before the vehicle can be moved.

After the appropriate exposure period, ventilate the structure as thoroughly as possible before reentering it. If the structure is a building, open roof vents and several doors from the outside to create a stack action, releasing most of the gas to the upper atmosphere. If the structure is a grain bin or silo, open the necessary vents and run the aeration fans. If you have to enter the structure, wear respiratory protection until the air-monitoring equipment indicates that the concentration of phosphine gas is less than 0.3 ppm (8-hour TWA) or 1.0 ppm (15-minute STEL). Finished foods and feeds that have been fumigated with phosphine must be aerated for 48 hours before being offered to the end consumer. An alternative is to analyze the commodity to prove that the phosphine residue is less than 0.1 ppm in animal feed, 0.01 ppm in processed foods, or 0.3 ppm for nonfood items.

All fumigants are dangerous, and their use requires specific training. All fumigants are restricted-use pesticides for application by trained and certified pesticide applicators only. This publication is intended to assist applicators who meet these requirements. It is always advisable, however, to consider using the services of a professional commercial fumigator to reduce both risk and liability.

Use fumigants according to the directions on the label. Follow all directions, precautions, and restrictions that are listed. Do not use fumigants on commodities or sites that are not listed on the label.

The fumigant rates listed in this publication are recommended only for those fumigants registererd with the Environmental Protection Agency and the pertinent state department of agriculture. If the label is cancelled or changed, the information contained herein is no longer recommended.

A video is availabel on this fumigation of on-farm grain bins. It is available on DVD or VHS. In Alabama, you can obtain a copy of this video from your regional agronomy agent of the Alabama, you can obtain a copy of this video from you regional agronomy agent of the Alabama Cooperative Extension System. Copies can also be obtained, at a cost of $15, from the Publications Distribution Office, Alabama Cooperative Extension System, Room 6 Duncan Hall, Auburn University, Alabama 36849. Make checks payable to the Alabama Cooperative Extension System. This video is available with a high-speed Internet connection at http://www.aces.edu/extcomm/satellite/fumig.wmv.

ANR-1154, Revised August, 2005.

Authors: Kathy Flanders, Extension Entomologist, Associate Professor, Entomology and Plant Pathology, Auburn University; and

Steve Brown, Extension Entomologist, Professor, Entomology, Georgia Cooperative Extension Service, University of Georgia

Notes: Figures 4, 5, and 6 are courtesy of IFC, Olathe, KS.

Use pesticides only according to the directions on the label. Follow all directions, precautions, and restrictions that are listed. Do not use pesticides on plants that are not listed on the label. The pesticide rates in this publication are recommended only if they are registered with the Environmental Protection Agency and the Alabama Department of Agriculture and Industries. If a registration is changed or cancelled, the rate listed here is no longer recommended. Before you apply any pesticide, fungicide or herbicide, check with your county Extension agent for the latest information.

Trade names are used only to give specific information. The Alabama Cooperative Extension System does not endorse or guarantee any product and does not recommend one product instead of another that might be similar.

For more information, call your county Extension office. Look in your telephone directory under your county’s name to find the number. Issued in furtherance of Cooperative Extension work in agriculture and home economics, Acts of May 8 and June 30, 1914, and other related acts, in cooperation with the U.S. Department of Agriculture. The Alabama Cooperative Extension System (Alabama A&M University and Auburn University) offers educational programs, materials, and equal opportunity employment to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.

Publication #: ANR-1154, Revised August, 2005.

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More