David W. Smith, Extension Safety Program

The Texas A&M University System

July 17, 2004. A 16-year-old male died from injuries sustained when the tractor he was driving overturned. The tractor was not equipped with a rollover protection structure or a general purpose enclosed cab. The tractor was capable of traveling at a maximum speed of approximately 16 to 18 miles per hour. The victim drove west on a paved highway that did not have shoulders. A passenger rode on the tractor to the driver’s left, leaning against the tractor fender. As the victim drove down the highway, the right wheels of the tractor left the road surface. As the tractor traveled forward, the right wheels cut into the soft, grass-covered ditch. Tracks in the grass indicated the victim turned the steering wheel sharply to the left to drive the tractor back onto the road. When the right front wheel struck the edge of the paved road surface, the tractor suddenly turned nearly cross ways in the road. As a result of the speed of travel and the sudden turn to the left, the tractor overturned. The tractor rolled to the right side and came to rest in an inverted position on the road. The victim was pinned underneath the tractor and pronounced dead at the scene. The passenger was slightly injured when he was thrown clear of the tractor and landed in a ditch.

Source: Minnesota FACE 94MN039.

According to the National Institute for Occupational Safety and Health (NIOSH), about 250 people are killed each year in tractor accidents. Rollovers account for more than half of these fatalities, despite decades of effort by tractor manufacturers and farm safety professionals to prevent such tragedies.

Drivers who wear seat belts and operate tractors equipped with rollover protective structures (ROPS) significantly reduce their risk of suffering rollover injuries. But because more than half of the 4.8 million tractors used on U.S. farms are not equipped with ROPS and the average age of farm tractors in use today is 25.7 years, it is not surprising that the number of fatalities involving rollovers has remained high.

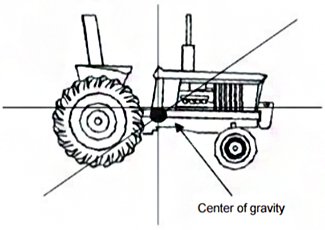

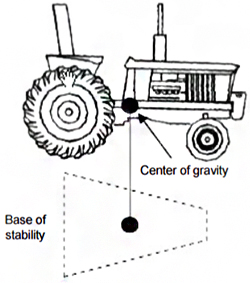

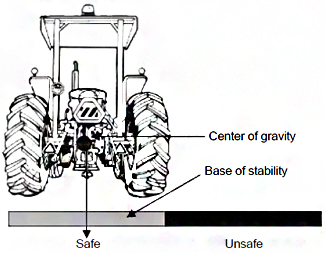

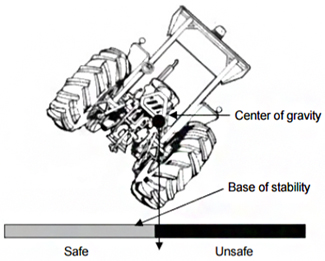

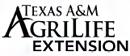

A tractor can roll over—to the rear or to the side— when its center of gravity is displaced outside its base of stability.

Center of gravity is defined as the point of equal weight distribution. This means that 50 percent of the tractor’s weight is distributed in front of this point and 50 percent behind. This same principle applies from side to side and top to bottom. On any given tractor, the center of gravity varies under different conditions.

Base of stability is defined as the area within the points where the tractor’s wheels contact the ground. The base of stability depends upon the front- and rearwheel spacing and the axle-to-axle spacing.

As long as the tractor is operated so that its center of gravity is within the base of stability, the tractor will not roll over.

About 85 percent of all tractor rollovers are side rollovers. The major causes of side rollovers are

Studies show that when tractor speed is doubled, the danger of rollover is increased four times.

Tractor manufacturers attempt to prevent side rollovers with design features and options that widen the base of stability and lower the tractor’s center of gravity. These features include

To reduce the risk of a side rollover operators should

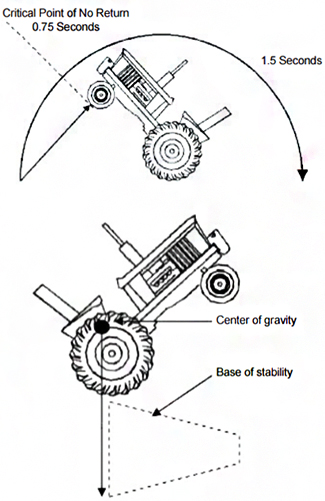

Rear rollovers are particularly dangerous because they happen so quickly, giving operators little time to react. Research shows that it takes only 0.75 seconds to reach the critical point of no return where the center of gravity moves over the rear axle and outside the base of stability. From the time the tractor begins to roll over, the incident can take as little as 1.5 seconds.

Rear rollovers are particularly dangerous because they happen so quickly, giving operators little time to react. Research shows that it takes only 0.75 seconds to reach the critical point of no return where the center of gravity moves over the rear axle and outside the base of stability. From the time the tractor begins to roll over, the incident can take as little as 1.5 seconds.

Some design features that reduce the risk of rear rollovers are standard on new tractors, while others are optional and are used in specific circumstances to maintain proper weight balance. These include

To reduce the risk of a rear rollover operators should

Rear rollovers can happen when tractors are stuck in mud and items are placed under the rear wheels to improve traction. Wheels stop slipping, rear torque causes the front end to rise off the ground, and the tractor’s center of gravity moves beyond the rear axle. When a tractor is stuck, always try to back it free first. If that doesn’t work, get another tractor to pull it out. Remember to attach the chain to the drawbar on the second tractor.

ROPS are protective frames attached securely to a tractor. They prevent the operator from being crushed if the tractor overturns. A seat belt prevents the operator from being thrown out of the protective zone. ROPS typically limit overturns to 90 degrees.

In 1976, the Occupational Safety and Health Administration (OSHA) passed a regulation that all tractors built after October 25, 1976 and used by farm employees must be equipped with ROPS. Furthermore, employers must ensure that all tractor operators wear seat belts. Low-profile tractors used in orchards, greenhouses and other buildings are exempt.

Legally, OSHA regulations apply to all farms with employees, even though OSHA cannot inspect farms with ten or fewer employees. OSHA regulations do not apply if a farmer uses only his or her own labor or uses only family labor. About 90 percent of all farms are small, with few or no employees, so the OSHA regulation does little to encourage the use of ROPS on most farms.

A more significant development in the promotion of ROPS occurred in 1985, when the American Society of Agricultural Engineers called for all new tractors to have a ROPS. Manufacturers now place ROPS on nearly all new tractors sold in the U.S., and make ROPS available as an option on models not fitted with ROPS at the factory.

Rollover injuries can be prevented by keeping the tractor from rolling over in the first place and by protecting the operator if a rollover does occur. To prevent a rollover, there are several ROPS designs available and others in the testing phase.

The four designs available at present are:

A new design being tested has a sensor that detects when a tractor is tilting, and then deploys a rollover bar to a level higher than the operator’s head. One objective of this design is to make it possible to have rollover protection in low-clearance areas, such as orchards, where standard ROPS designs cannot be used.

Many older model tractors can be retrofitted with ROPS, although retrofits for some models may be hard to find. The National Farm Medic Clinic (Marshfield Clinic) in Marshfield, Wisconsin has an online database of ROPS suppliers for many tractor makes and models.

The Guide to Agricultural Tractor Rollover Protective Structures lists sources of retrofits.

When retrofitting a tractor with a ROPS frame or cab, seat belts also must be installed. The seat belt is provided in some ROPS packages. In some instances the seat may have to be replaced. Ask the supplier about seat belts for the particular make and model of tractor you need to retrofit.

A ROPS must be installed correctly, according to the manufacturer’s instructions. Retrofits require special hardware and extra-strength bolts and fasteners. A ROPS should never be modified by drilling, cutting, welding or any thing else that could weaken its structure and cause it to fail during a rollover.

Constructing a homemade ROPS is strongly discouraged. Manufactured ROPS are specifically designed to conform to the tractor’s load-bearing capacity, weight distribution, and strength of construction. Homemade ROPS are often made of inferior materials and are not attached properly to the tractor frame. Homemade ROPS often fail during a rollover.

References

Myers, J.R. and K.A. Snyder. Rollover protective structure use and the cost of retrofitting tractors in the United States, 1993. Journal of Agricultural Safety and Health. 1996. 1:185-97.

National Institute of Occupational Safety and Health. National Agricultural Tractor Safety Initiative. January 2004.

National Safety Council. Injury Facts.

United States Department of Agriculture. Bureau of Labor Statistics. Census of Fatal Occupational Injuries. 2002.

The Texas A&M University System Extension publications can be found on the Web at: http://www.agrilifebookstore.org/

Visit Texas Cooperative Extension at https://agrilifeextension.tamu.edu/

Educational programs conducted by Texas Cooperative Extension serve people of all ages regardless of socioeconomic level, race, color, sex, religion, handicap or national origin. Issued in furtherance of Cooperative Extension Work in Agriculture and Home Economics, Acts of Congress of May 8, 1914, as amended, and June 30, 1914, in cooperation with the United States Department of Agriculture.

Edward G. Smith, Interim Director, Texas Cooperative

Publication #: E-344 04/05

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More