Too often, hazards are discovered or addressed only after a worker is harmed or dies.

Becoming aware of possible hazards is the first step to preventing tragic incidents that can have devastating impacts on workers, farmers, and even the community.

Every farm is unique but all have hazards associated with cattle handling, manure storage, and machinery and equipment.

Activities include moving cattle around the farm, feeding and milking cows, and cleaning stalls and beds.

--Cows get stressed and can strike, pin or step on workers.

--Identify and eliminate (or minimize) as many stressors as feasible. These can vary based on the handling activity, physical surroundings, tameness of the individual cow and other variables.

--Avoid the blind spot; approach slowly so cows can see you and speak calmly. Fresh cows may have a larger flight zone.

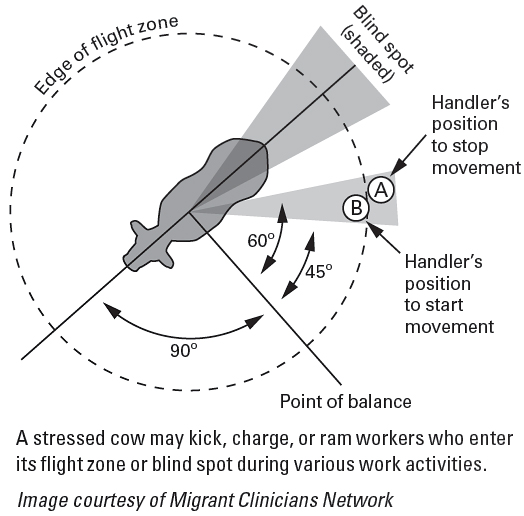

--Instead of using prods or touching cows to get them to move forward, backwards or around, learn how to use the “point of balance” technique. See illustration.

--Tell workers about how they can get hurt, what causes stress for cows (e.g. startling noises, sudden contact, etc.) and how to recognize signs of stress. Demonstrate what workers can do to minimize stressors that can make cows nervous and unpredictable.

--Be aware of gates and other escape routes available; wear crush-resistant footwear (steel-toed boots).

Locations include liquid manure and slurry storage pits, ponds, lagoons or tanks.

--Driving a farm vehicle too close to the edges of a manure storage site can cause the vehicle to tip over into the manure. --Decomposing manure creates a breathing hazard zone in enclosed areas or confined spaces because toxic gases can accumulate and quickly overcome workers and cause them to fall into the manure and suffocate.

--Manure contains bacteria and other pathogens that can make workers sick.

--Damaged or poorly set up ladders can result in tip overs and falls.

--Install a fence, concrete “ecology” blocks or other barriers around storage sites and place warning signs to prevent entry.

--Cover manure pits and tanks and post warning signs to keep unauthorized personnel out.

--Train workers about the dangers of manure pits, ponds, lagoons and tanks and instruct them about what they’ll need to do stay safe.

-- Follow permit-required confined spaces rules if workers need to enter manure storage tanks and other confined spaces to inspect, make repairs, clear blockages or do other tasks.

-- Wear appropriate PPE to protect against contact with bacteria and other harmful pathogens in animal waste. Wash hands frequently so you don’t spread waste contamination. ]

The edges around manure storage sites can appear

deceptively solid.

Here is one possible solution that

can prevent entry. Photo: L&I.

Included are skid steers, tractors, power take-off shafts (PTOs), feed mixers, manure spreaders, augers and hay balers.

Key hazards for these sources:

-- Exposed moving mechanical parts like rotating shafts, belts and pulleys, flywheels and gears, chains and sprockets, blades and shear points can catch workers’ hands, feet, hair or clothing and cause life threatening injuries. The risk for harm increases when operating equipment, clearing jams and making adjustments.

Respect machinery that can maim or kill, like

this feed mixer. Proper safety covers and

training on safe work practices can prevent

tragic lessons.

Photo: WorkSafeBC

-- Dangerous movement of machinery due to unexpected start up or release of stored hydraulic, electrical, pressure and other types of energy can hurt workers during inspections, maintenance, cleaning and repairs.

-- Rollovers when driving a skid steer or tractor.

-- Drivers can fall when getting in and out of a skid steer or tractor.

-- Entering spaces in large machinery may expose workers to confined space dangers (e.g., engulfment, amputation, electrocution, suffocation).

-- When you buy machines, look for well-designed safety features like covers or guards for dangerous moving parts.

-- Keep machine safeguards in place and maintained.

-- Safely install covers and other safeguards according to the manufacturer’s specifications.

-- Develop and follow lockout/tagout procedures and provide lockout devices (e.g., locks, tags) to prevent unexpected start-up of equipment.

-- Train workers on mechanical hazards and safety procedures (including lockout/tagout) for operating machinery, removing jams, cleaning and other tasks.

-- Keep clothing and hair secured so it can’t get entangled.

-- To reduce risk for skid steer and tractor rollovers, don’t overload the bucket and keep it low. Seat belts and rollover protection systems (ROPS) save lives during rollovers.

-- Follow the “3-point contact” rule when getting into a skid steer or tractor. Don’t jump.

-- Follow permit-required confined spaces rules if workers need to enter confined spaces to inspect, make repairs, clear blockages or do other tasks. Visit www.Lni.wa.gov/DairySafety to find L&I’s Dairy Industry webpage and get more information about hazards and solutions, access to safety rules, sample APPs, videos, training materials and other resources to strengthen your farm’s safety program.

Strengthen your farm’s safety program!

Like other employers in Washington State, dairy farms are required to set up and follow a written Accident Prevention Program (APP) that addresses their particular workplace hazards.

Upon request, foreign language support and formats for persons with disabilities are available. Call 1-800-547-8367. TDD users, call 360-902-5797. L&I is an equal opportunity employer.

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More