2.0 APPLE PACKING PROCESS

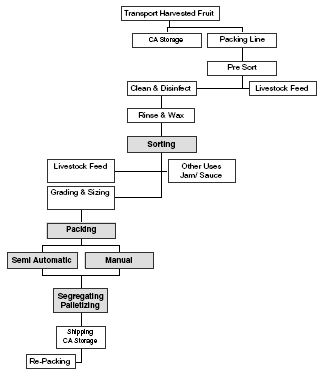

The apple packing process has been fairly well standardized across the industry with some minor modifications between companies (see Figure 1). Peleg provided a thorough overview of the process that generally includes sorting, packing, and segregating (Peleg, 1985). Job categories of primary interest to the Field Group were sorting, packing (including both manual and semi-automatic) and segregating.

Figure 1 Apple Packing Process

2.1 Sorting

The packing line begins with the transport of bulk bins of fruit directly from the orchard or

from controlled atmosphere storage to the packing line. As large-scale use of controlled

atmosphere (CA) storage became more common in the 1970s and 1980s, packing houses

could hold large amounts of fruit for up to one year. This technological advance allowed

packing houses to move from seasonal to year-round work. Bins can weigh between 450 to

1,100 pounds depending on their capacity and fill level, and are transported to the packing line by forklift. Apples are fed onto the packing line either by hydro handling (immersion of bins in a soaking tank allowing the fruit to float out of the tote) or by dry feeding (tipping full bins onto a receiving conveyor belt). Severely damaged or rotten fruit is removed in an initial sort. Apples are then cleaned by soaking them in water that contains detergents and disinfectants and are then transported via a series of rotating brushes, under a rinse-water spray, to a dryer. The apples are dried by rotary sponges and overhead fans then they are sprayed with food-grade wax to improve storage and visual appeal. The clean apples are pre-sized by hand with workers selecting out undersized or damaged fruit, referred to as culls. Culls are used for livestock feed, jams, canning, applesauce, or cider.

After cleaning, waxing, and pre-size sorting, the apples move onto a roller-sorting table for final sorting. The roller-sorting table is designed to continually rotate fruit as it moves past human graders (AKA: sorters). Sorters pick out one or more grades that comprise the minority of the fruit flow (usually very large apples) while the predominate grade is allowed to flow onto the next processing station. This is known as “Reduction Sorting” and is the most common type of sorting performed in apple packing houses. Sorters also inspect apples for shape, color, bruising, insect and mite damage, sunburn, rot, and cuts. Rejects and culls are removed from the flow and are either thrown in a bucket for disposal or down a chute for other product processing. Sorter task cycle includes: 1) checking fruit quality, 2) deciding on the grade, 3) stretching out a hand to pick out and discard minority or defective fruit from the moving flow, and 4) monitoring the fruit as it moves on to the next operation. Sorters repeat this cycle thousands of times per shift.

Apples continue down the sorting conveyor line to a computer-controlled sizer. The sizer is programmed to evaluate the fruit by size and color. It labels each apple with a pressure sensitive adhesive label, and delivers the fruit to grade-specific conveyors leading to the packers. The sizing system concurrently collects information on total volume of fruit packed, fruit grade, size and source (orchard or grower).

2.2 Packing

Apples are packed into a variety of containers, primarily into boxes with trays or into bags or bins. The particular type of packing conducted at a packing house is determined by the type of apples (delicate fruit is usually boxed in trays) and design of the packing house. Also, client needs may determine the type of container (e.g. Costco and Wal-Mart require specialized box containers, other clients request display bins and bulk bins). Apples are boxed by size, ranging from 38 to 150 apples per box, with 88 apples per box being the most common size.

Packing can be divided into manual and semi-automatic processes. Manual packing is done with delicate varieties (such as galas), to meet client requests, and in small packing houses. Larger and some small packing houses have automated most of the packing processes. Workers may do both manual and semi-automated packing and pack into a variety of containers over the course of a single work shift, depending on the client needs, fruit varieties, and production abilities and standards of the packing house.

Manual packing workstations receive apples from the computer-controlled sizer via a conveyor according to the size and grade of the apple. Apples are delivered to the packers on conveyors or are deposited into rotating receiving tubs. Packers stand either to the side of or directly in front of the conveyor or tub; the physical dimensions of the workstation often require that the packer lean and twist over the conveyor or tub in order to reach the apples. The packers usually retrieve an apple with one hand, transfer the apple to the other hand, and then place it into waiting paper trays or bags. Some packers may fill box trays with two hands. The packer at piece-rate companies sets the work pace within the pace set by the automated filling of the receiving bins. The conveyor speed sets the work rate at companies that pay an hourly rate. Paper trays have indentations appropriately sized for a particular size of apple. Tray indentations determine the number of apples that can be placed in one tray. Each standard apple box holds five or six trays depending on the apple size. Full boxes weigh 40 to 50 pounds.

Packers may use pre-made boxes or be required to fold and make each box. Each box to be manually packed is held on a rolling cart that is called a “packing horse.” Two designs of packing horse cart box holders were observed during this pilot project: roller tray and slide tray packing horses. The roller tray carts are a newer design and allow filled boxes to be easily pushed from the packing horse directly onto the next conveyor system without lifting the full box of apples. The slide tray packing horse requires the packer to lift the tray upon which the full box is sitting and slide or push the box onto the next conveyor system.

Some packing houses have moved to semi-automatic tray packing. Indented paper trays are mechanically or manually fed into the packing conveyor where they meet apples delivered from the computer-controlled sizer. Apples are gently rolled off the sizing conveyor onto the paper trays that are conveyed on to the packers. Packers manually adjust each apple in its tray for optimal presentation. The pace of the semi-automatic tray filling is determined by the speed of the conveyor. Filled trays are manually placed in boxes that are located at the end of each packing conveyor; full boxes are pushed onto another conveyor for labeling and delivery to storage.

Semi-automatic bagging has also been instituted in some packing houses. Apples are delivered from the computer-controlled sizer to either a standing or sitting semi-automatic bagging station. Apples roll from the delivery conveyor to a bagging machine chute that will hold a preset weight of apples. When the chute is full, the packer depresses a floor foot pedal to deliver the apples into an air-inflated bag. The bag is usually held in two hands, though some packers hold the bag in one hand. After the bag is full, the packer lifts it up with one hand, twists it, and applies a plastic closure clip or twist tie with the other hand. Closure clips may also be applied automatically. The bag is then placed with one hand onto another conveyor, which is either in front or behind the worker, for delivery to the labeling station and storage area.

Repacking. Often boxes need to be repacked to meet production needs, client requests for different containers, quality control requirements, or USDA requirements for storage limits. If the number of pallets to be repacked is small, repacking is done manually by the most experienced packers. This work is usually not performed at a standard packing station, but rather takes place at any available table. Apples are manually removed from one box, sorted, graded, and repacked in another box.

2.3 Segregating

Once boxes have been packed, labeled, and inventoried, segregators (usually male workers) manually lift boxes from a delivery conveyor and place them on wooden pallets according to labeled size and grade. A typical packing house may pack as many as 15 different apple varieties, sizes, and grades at once, and each must be stacked on a separate pallet. The boxes are stacked seven high, to approximately seven feet. Once the pallet is full, boxes are secured with twine and forklifts transport the pallets to the loading dock or to storage. Some packing houses use an automatic palletizer that stacks and shrink-wraps the boxes on pallets. The Yakima Valley Growers-Shippers Association reported that 81.6 million boxes of apples were processed in 1999 (YVGS, 1999).

Back to Table of Contents

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More