|

!

Workers loading,operating,or working near refuse compacting

or baling equipment are at risk of serious injury and

death.

|

WORKERS

should take the following steps to protect themselves from injury

when operating or working near compacting and baling equipment

:

- Never bypass or disable interlocks or control switches.

- Keep all equipment guards in place during operation.

- Before attempting to clear jammed material from a compactor

or baler,follow OSHA standards on lockout/tagout procedures

[29 CFR 1910.147 ]:

- Disconnect the power from the machine.

- Isolate the power by locking the disconnect.

- Tag the disconnect to notify others that the power must

remain off.

- Mechanically block any ram that has the potential to

move before accessing the compacting chamber.

- Test equipment to ensure power has been de-energized

before beginning work.

- Locate all coworkers before activating power to the compactor

or baler.

EMPLOYERS should take the following steps to reduce

the risk of worker injuries and deaths:

- Establish procedures for periodic inspection and maintenance

of the equipment:

- Maintain equipment guards according to the manufacturer

's specifications.

- Check for proper operation of all interlocks and

emergency stop devices.

- Train workers to recognize compactor and baler hazards.

- Implement standard procedures for dealing safely with

material jams.

- Provide safe access to feed chutes for clearing material

jams.

- Comply with child labor laws that prohibit hazardous

work by workers under age 18.

The National Institute for Occupational Safety and Health

(NIOSH)requests assistance in preventing deaths and injuries

among workers who load,operate, or work near refuse compacting

or baling equipment. Recent NIOSH investigations suggest that

worker injuries and deaths could be prevented by using safe

work procedures,appropriate safety devices,and hazardous energy

control programs designed to address the hazards of operating,maintaining,

and servicing compacting and baling equipment. This Alert describes

five cases of fatal injuries that resulted when workers entered,fell,or

were caught and pulled into energized compacting or baling equipment.

The National Institute for Occupational Safety and Health

(NIOSH)requests assistance in preventing deaths and injuries

among workers who load,operate, or work near refuse compacting

or baling equipment. Recent NIOSH investigations suggest that

worker injuries and deaths could be prevented by using safe

work procedures,appropriate safety devices,and hazardous energy

control programs designed to address the hazards of operating,maintaining,

and servicing compacting and baling equipment. This Alert describes

five cases of fatal injuries that resulted when workers entered,fell,or

were caught and pulled into energized compacting or baling equipment.

All managers,supervisors,and workers in companies that use compacting

or baling equipment should follow the recommendations in this

Alert. NIOSH requests that equipment manufacturers,safety and

health officials,industry associations,unions,and editors of

trade journals bring the recommendations in this Alert to the

attention of all employers and workers who use compacting and

baling equipment.

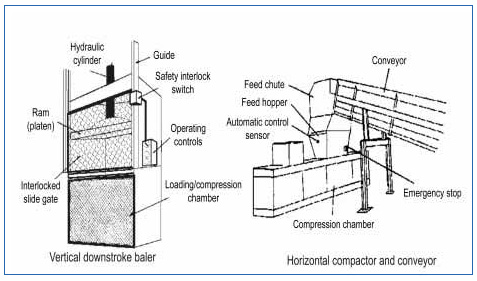

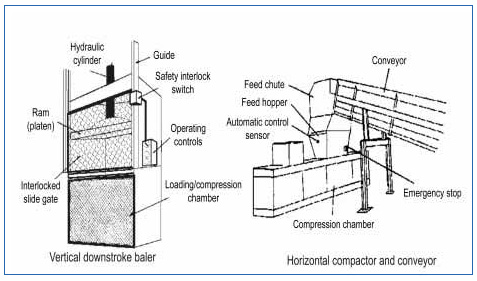

Compacting and Baling Equipment

Compacting and baling equipment reduces large amounts of solid

waste to smaller, more manageable units by means of powered

rams. These machines may be used by manufacturing companies

to compact and bale large amounts of scrap and waste materials

such as paper,cotton,and metals,and by retail and service industries

to compress paper and cardboard boxes. Compactors compress the

refuse material into containers for transport. Baling equipment

is designed to compress material and produce a bale (bound or

unbound)that can be handled and transported as a material unit.

Compacting and baling equipment are available in many sizes

and configurations. These machines may have one or more rams

for compressing materials or extruding bales. The rams may move

vertically or horizontally (Figure 1).

Figure 1. Diagram of a vertical downstroke baler and

a horizontal compactor and conveyor.

Figure 1. Diagram of a vertical downstroke baler and

a horizontal compactor and conveyor.

Some types of equipment allow direct access to the compression

chamber. Others have a hopper or chute through which material

feeds into the machine. In businesses where refuse processing

is incidental to the primary operation (such as in retail and

service industries),loading and compressing may be done as separate

work activities —that is,material may be intermittently loaded

until the chamber is full and then compressed. Alternatively,in

businesses where compressing scrap and waste materials is the

primary operation or where large volumes of refuse materials

are processed daily,loading and compressing is a continuous

operation.

Machines may operate in a manual,semiautomatic,or automatic

mode. In the manual mode,a switch operated by a worker controls

ram motion. In the semiautomatic mode,an operator initiates

the compression,after which the machine automatically completes

the cycle. In the automatic mode,a sensor inside the compression

chamber signals when the chamber is full and activates the compression

cycle.

Workers at Risk

Because of the widespread use of compactors and balers across

varied industries,it is difficult to obtain exact numbers of

workers who are exposed to the hazards of this equipment. The

workers most likely to be exposed to risk from compacting and

baling equipment are those in the wholesale trade and transportation/public

utilities industries engaged in recycling and the collection

and disposal of refuse. Employees working in manufacturing settings

and in retail and service trades may also be at risk because

of the large volume of waste generated and processed daily.

Fatality Data

The Census of Fatal Occupational Injuries (CFOI)is a multisource

data system maintained by the Bureau of Labor Statistics to

identify work-related deaths in the United States. A NIOSH review

of the CFOI data identified 34 compactor-related fatalities

during 1992 –2000 in which the victim was caught in or crushed

by the compacting ram of the machine [NIOSH 2003 ].

The age range of the fatally injured worker was as follows:

| Age |

Number

of fatalities |

| <25............ |

8 |

| 25

–35 .......... |

10 |

| 36

–45 .......... |

8 |

| >46............ |

8 |

Industries involved were the following:

| Industry |

Number

of fatalities |

| Wholesale

trade ......... |

13 |

| Manufacturing

........... |

7 |

| Transportation/public

utilities ... |

7 |

| Retail

trade/services........ |

7 |

The following materials were being compacted at the time the

victim was crushed:

| Material |

Number of incidents |

| Cardboard ............ |

7 |

| Paper .............. |

7 |

| Trash/garbage .......... |

6 |

| Other/not specified ....... |

7 |

The NIOSH Fatality Assessment and Control Evaluation (FACE)Program

has con- ducted fatality investigations of selected types of

incidents since 1982.*Incident types include electrocutions,falls

from elevation,machine-related,and confined- space-related fatalities.

The goal of the FACE Program is to prevent occupational fatalities

by (1)identifying and investigating work situations that involve

high risk for worker injury and (2)formulating and disseminating

prevention strategies.

During 1992 –2002,FACE received 20 re- ports of compactor-related

fatalities. All of the fatally injured workers were males whose

ages ranged from 16 to 72 and were either caught in or crushed

by the machine. In-depth investigations were conducted for 13

of these cases in which the victim was crushed in the compacting

chamber or suffered amputation from being caught between the

ram and the compacting chamber walls. In all cases,the fatally

injured worker either reached or fell into the compression chamber.

One or more additional risks were also present in each case.

In five of the cases,the victim had been in the process of clearing

jammed material from the machine just before the injury. In

six of the cases,the machine cycled automatically when the victim

entered the compacting chamber;and in three of the cases,coworkers

activated the machine without knowing that a worker was inside

the compacting chamber. In two of the cases,the fatally injured

worker was attempting to retrieve material from the machine.

Occupational Safety and Health Administration (OSHA)

No current OSHA standards apply specifically to compacting and

baling equipment. However,current OSHA regulations on the control

of hazardous energy sources (lockout/tagout)[29 CFR † 1910.147],and

machine guarding [29 CFR Part 1910.212 ] are applicable to these

types of equipment. In addition,the confined space standard

[29 CFR 1910.146 ]may apply to entry into compacting and baling

equipment. An OSHA publication,Concepts and Techniques of Machine

Guarding ,describes and illustrates methods that can be used

for providing safeguards for balers and compactors [OSHA 1992

].

Fair Labor Standards Act (FLSA) and Youth Employment

The FLSA is the primary Federal law governing the employment

of workers under age 18. Regulations issued under the FLSA (as

amended by the Compactors and Balers Safety Standard Modernization

Act of 1996, Public Law 104 –174)prohibit children under age

18 from servicing,loading,operating,unloading,or assisting in

the operation of compacting equipment. These prohibitions are

specified under Hazardous Occupations Order No.12 (Power-Driven

Paper-Products Machine Occupations [DOL 2001 ].The current prohibitions

are specific to machines that are used exclusively to compact

and bale paper products. Though no final action has been taken,

the Department of Labor has proposed amending Hazardous Occupations

Order No.12 to expand the ban to balers and compactors used

to process other materials in addition to paper such as aluminum

cans,plastic,foam,and rubber [64 Fed. Reg. ‡ 67130 (1999)].NIOSH

supports this amendment since balers and compactors used to

process scrap materials other than paper products pose similar

risks of injury and have been associated with fatal injuries

[NIOSH 2000a ].

The FLSA (as amended)provides a limited exemption that allows

workers aged 16 and 17 to load only (place materials in) but

not to operate or unload materials from scrap paper balers and

cardboard box compactors that meet certain operation and construction

standards. The machines must not be able to operate while being

loaded. They must be equipped with a lockable on-off switch

that is maintained in the off position when the machine is not

in operation,such as during loading. The machine must comply

with the ANSI Z245.5 –1990 standard for baling equipment and

ANSI Z245.2 –1992 standard for compactors. The employer must

provide and post a notice that the machine meets the applicable

construction standards. Workers aged 16 and 17 may load the

machine,but no worker under age 18 may operate or unload material

from the machine. Compliance with these provisions can protect

adolescent workers from compactor and baler hazards by eliminating

exposure to moving machine parts and ensuring that older,more

experienced workers are available to operate and unload materials.

American National Standards Institute (ANSI)Standards

ANSI publishes voluntary standards addressing safety requirements

for a variety of equipment,including compactors and balers.

These standards were last revised in 1997. Stationary compactor

safety requirements are outlined in ANSI Z245.2 1997 [ANSI 1997a

],and baling equipment is addressed in ANSI Z245.5 –1997 [ANSI

1997b ].

The key points of the ANSI standards state the following:

- Employers shall provide workers with instruction and

training in safe work methods before assigning them to operate,clean,service,maintain,or

repair the equipment.

- The worker shall be responsible for using the safety

features on the compactor or baler.

- The worker shall ensure that all persons are clear of

the point of operation before starting up the machine or

a compactor cycle.

- The employer shall inspect safety interlocks,switches,and

other protective devices to ensure that they are not disabled

or bypassed. The employer shall not permit operation of

the baler unless these devices are fully functional.

The five cases described here are deaths investigated by the

FACE Program.

Case 1

On March 7,2001,a 36-year-old male paper factory worker died

from crushing injuries after being caught by the ram inside

a two-stage horizontal baling machine (Figure 2).The victim,working

alone in the warehouse area of a paper plant, was compacting

waste paper when he entered the compression chamber (either

through the access door or from the top of the feed chute) to

clear a jam and was caught by the machine 's hydraulic ram.

Investigation revealed that the baler was not shut off and locked

out before the victim entered it and that the safety interlock

on the compression chamber door may have malfunctioned,allowing

the machine to operate with the door in the open position [NIOSH

2001 ].

Figure 2.

Figure 2. Automatic two-stage horizontal baler.

Case 2

On July 27,2000,a 16-year-old male produce market worker died

as a result of crushing injuries from a baling machine used

to compress waste cardboard boxes for disposal and recycling

(Figure 3).The victim,working alone in the basement of a small

produce market,was crushing and baling cardboard boxes when

he was caught in the hydraulic ram. An investigation of the

incident by the police found that the baler was being operated

improperly,with the loading chamber door open and the door safety

interlocks bypassed with a wad of paper. When the victim was

found,it appeared that he had been starting a new bale. The

wire had been threaded through the compression chamber and secured

to the outside of the compactor,and a flattened box was in place

in the base of the compactor chamber. The victim may have leaned

over into the compression chamber trying to quickly adjust a

tie wire or the base box when he was caught by the ram as it

moved downward [NIOSH 2000b ].

Figure 3.

Figure 3. Vertical downstroke baler.

Case 3

On September 30,1999,a 24-year-old male machine operator died

from crushing injuries after he fell into a baling machine used

to compress and bale waste cardboard for recycling (Figure 4).The

victim worked alone loading,compressing,and moving completed

bales to a storage area. The victim was last seen around 5 p.m.

during a break. Between 5:30 and 7 p.m., the victim may have

climbed up the outside walls of the conveyor to dislodge a piece

of cardboard that was jamming the conveyor belt — an act he

had been observed performing in the past. Workers reported that

occasionally cardboard would become lodged in the top part of

the hopper just under the conveyor (an area that measures 28

by 8 inches),causing the hopper to jam. During this action,the

victim may have lost his balance and fallen into the compression

chamber,thereby tripping the automatic sensor that indicated

that the chamber was full and caused the baler to cycle [NIOSH

2000c ].

Figure 4.

Figure 4. Automatic conveyor-fed baler.

Case 4

On May 9,1997,a 34-year-old laborer at a paper products plant

died after falling into an operating paper compactor (Figure

5). The victim and a coworker were loading scrap paper into

the automatically operated compactor via a belt conveyor when

the material jammed in the feed chute. The coworker shut down

the conveyor,but the compactor 's controls remained in automatic

mode. The victim climbed up to a platform between the conveyor

discharge and the feed chute to clear the jam. When the victim

leaned over the platform rail to clear the jam,he fell into

the compression chamber. His presence tripped the automatic

control system, and the compactor 's ram was automatically activated

[NIOSH 1997 ].

Figure 5.

Figure 5. Automatic conveyor-fed horizontal baler.

Case 5

On April 17,1996,a 72-year-old recycling center laborer was

crushed to death after falling into the loading chamber of an

industrial baling machine (Figure 6).The incident occurred as

the victim and his coworkers were baling discarded newspapers

in a vertical upstroke baler. This machine used a 12-foot-deep

pit in the floor as a loading chamber. The victim,a “broom-man

”who usually swept loose material into the baler,was working

near the machine when he apparently fell into the loading chamber

pit. His coworkers,not knowing that he was in the baler,filled

the loading chamber with newspapers and started the machine

[NJ FACE 1996 ].

Figure 6.

Figure 6. Vertical upstroke pit baler.

Compacting and baling equipment has widespread use across varied

industries. The incidents discussed in this Alert involve hazardous

work practices,the lack or failure of safety devices,and failure

to develop and implement standard lockout/tagout procedures.

Information from the FACE investigations indicates that workers

suffered fatal injuries when they entered the compactor to clear

a jam,fell into the travel path of the ram,or reached into the

ma- chine while performing operational procedures. Employers

who recognize the need to implement lockout/tagout procedures

during maintenance may not fully appreciate that clearing jammed

material poses a similar risk of injury to workers and should

be conducted using standard procedures that include appropriate

hazardous energy control methods.

Failure to de-energize the equipment and ensure that the device

could not be inadvertently reactivated contributed to some of

these fatalities. In addition,compacting and baling equipment

and any attached conveyors could have been interconnected so

that a single lockable device could de-energize and isolate

the power to both machines during lockout/tagout procedures.

Failure of safety devices and lack of instruction and training

in the operation of the equipment may have contributed to some

of these deaths. The circumstances involved in these cases indicate

that workers may not fully appreciate the hazards of entering

or working near feed hoppers of energized compacting and baling

equipment.

NIOSH recommends that employers take the following measures

to protect workers from injury when operating or working near

refuse compacting and baling equipment.

Lockout/tagout

Because ram motion ceases during a jam, workers may not recognize

that the machine remains operational and the ram could activate

inadvertently unless the power supply for the machine is disconnected.

Whenever unjamming,performing maintenance,or repairing a compactor

or baler,the machine should be de-energized and OHSA 's lockout/tagout

procedures [29 CFR 1910.147 ]should be followed. At a minimum,lockout/tagout

procedures should include the following elements:

- A statement of how the procedure will be used

- Training for workers in the specific hazards of each machine

- Identification and marking of power disconnects

- The steps required to shut down,isolate,block,and secure power

to the machines

- The steps designating the safe placement,removal,and transfer

of lockout/ tagout devices and the person who has the responsibility

for them

- The specific requirements for testing machines or equipment

to determine and verify the effectiveness of locks, tags,and

other energy control measures

- Notification of workers by the employer or an authorized worker

before lockout or tagout devices are applied and before they

are removed from the machine

Additional recommendations for developing and implementing a

hazardous energy control program are included in

NIOSH Alert

:Preventing Worker Deaths from Uncontrolled Release of Electrical,Mechanical,and

Other Types of Hazardous Energy [NIOSH 1999 ].

Machine Guarding

Compactors and balers should be equipped with machine guards

and safety interlocks to prevent worker injury,and interlocks

should be designed so they are not easily bypassed. All machines

should be equipped with safety interlock devices that will immediately

stop the machine should a worker attempt to gain access to a

ram or the travel zone of the ram while the machine is operating.

Currently manufactured compactors and balers conform to ANSI

standards that specify point-of-operation guards to prevent

workers from reaching into an operating machine and interlocked

control systems that interrupt or reverse the ram 's motion

if the compression chamber doors are opened. However,guards

and interlocks may be deliberately bypassed or may not be present

on some older machines.

Where conveyors are used to feed materials into compactors or

balers,workers may mistakenly believe that turning off the conveyor

also prevents the compactor or baler from operating. To protect

against this, compacting and baling equipment and any attached

conveyors should be interconnected so that a single lockable

device can be used to de-energize and isolate the power to both

machines. In addition,all emergency stop devices should be interconnected

so that the activation of any emergency stop will shut down

both the conveyor and the compactor or baler.

ANSI Z245.2,and Z245.5,and 29 CFR 1910.212 provide information

about machine guarding. These standards also provide information

about modification of older equipment to improve safety. Any

modifications made to equipment should be done only by qualified

persons. In addition, descriptions and illustrations of methods

that can be used for providing safeguards for balers and compactors

can be found in the OSHA Publication entitled Concepts and Techniques

of Machine Guarding [OSHA 1992 ]. Machine guards and safety

interlocks should be frequently checked by safety personnel,supervisors,and

workers to assure that they are in proper working order.

Work Practices and Procedures

Jams are common occurrences in compacting and baling machines.

Employers should implement standard procedures for dealing safely

with common events such as material jams. Employers should train

their workers in these safe work procedures and strictly enforce

adherence.

Fatalities have occurred when machines were activated while

the operator was unaware that a coworker was inside the compacting

chamber. Employers should establish procedures requiring machine

operators to account for the location of coworkers before activating

compactor or baler rams.

Safe Access and Fall Protection

Because jams often occur at the openings to feed chutes of conveyor-fed

machines, workers may use the conveyor as a means of access

to the jam. Platforms incorporating stairs and standard railings

should be provided near the openings of feed chutes to allow

safe access for clearing jams. In addition,employers should

consider providing workers with fall protection devices, harnesses,and

lanyards to prevent them from falling into the feed chute if

they inadvertently lean over the platform railing while clearing

jammed material. Although neither of these measures eliminates

the need to follow appropriate lockout/tagout procedures,their

use could provide extra protection for workers.

Training

Employers should train workers to recognize the hazards of operating

or working near compactors and balers. Procedures and safe work

practices addressing problems that may develop during machine

operation should be developed and implemented. At a minimum,training

should include the following elements:

- A description and identification of the hazards associated

with particular machines

- The safeguards themselves,a description of how they provide

protection, and a list of the hazards for which they are

intended

- Instructions for using the safeguards

- Instructions for removing the safeguards (these should

include the circumstances under which they can be removed

and the persons who can remove them — most cases,repair

and maintenance personnel only)

- What to do (e.g.,contact the supervisor)if a safeguard

is damaged,missing,or unable to provide adequate protection

Protecting

Adolescent Workers

Employers should not assign workers under age 18 to service,

load, operate, or assist in the operation of compacting or

baling equipment. For cases in which the Compactors and Balers

Safety Standard Modernization Act applies,employers should

comply with all provisions of the Act —including ensuring

that the compacting or baling equipment meets specified safety

standards and that young workers are limited to loading materials

into de-energized equipment. When training young workers on

their job and work procedures, employers and supervisors should

explicitly note restrictions on having young workers load

and operate compacting or baling equipment. All workers in

the work setting should be aware of any workers under age

18 and be similarly trained so that they do not assign them

to work with compactors or balers and can notify the employer

or supervisor should violations of the policy occur. For stickers

that employers can post on the machine to alert workers of

the age requirement,see http://youthrules.dol.gov/news/posters-stickers-bookmarks/index.htm

The principal contributors to this Alert were Joe Burkhart

and Paul Moore of the NIOSH Division of Safety Research. Cases

presented in this Alert were contributed by the NIOSH FACE

Program and by Patrick Bost of the New Jersey State-Based

FACE Project. Additional reports from FACE investigations

are available at the NIOSH Internet site.

Please direct any comments,questions,or requests for additional

information to the following:

Dr.Nancy Stout,Director

Division of Safety Research

National Institute for Occupational Safety and Health

1095 Willowdale Road

Morgantown,WV 26505–2888

Telephone:304 –285 –5894

For further information about occupational safety and health

topics,

call 1–800–35–NIOSH (1–800–356–4674),or visit the NIOSH Web

site at www.cdc.gov/niosh

We greatly appreciate your assistance in protecting the health

of U.S.workers.

John Howard,M.D.

Director

National Institute for Occupational Safety and Health

Centers for Disease Control and Prevention

ANSI [1997a ].American national standard for equipment technology

and operations for wastes and recyclable materials stationary

compactors—safety requirements. New York:American National

Standards Institute,Inc.,ANSI Z245.2–1997.

ANSI [1997b ].American national standard for equipment technology

and operations for wastes and recyclable materials—baling

equipment—safety requirements. New York:American National

Standards Institute,Inc.,ANSI Z245.5–1997.

CDC (Centers

for Disease Control and Prevention)[2001 ]. Baler and compactor-related

deaths in the workplace—United States,1992–2000. MMWR 50 (16):309–313.

CFR. Code of Federal regulations. Washington,DC:U.S. Government

Printing Office,Office of the Federal Register.

DOL [2001 ].Child labor requirements in nonagricultural occupations

under the Fair Labor Standards Act. Child Labor Bulletin 101.

Washington,DC:U.S. Department of Labor,Employment Standards Administration,Wage

and Hour Division,WH1330.

64 Fed.Reg.67130 [1999 ].Department of Labor,Wage and Hour Division,Employment

Standards Administration:29 CFR Parts 570 and 579:child labor

regulations, orders,and statements of interpretation; child

labor violations—civil money penalties;proposed rules.

NIOSH [1997 ].Laborer dies after falling into baler at paper

products plant—South Carolina. Morgantown,WV:U.S. Department

of Health and Human Services,Public Health Service,Centers for

Disease Control and Prevention,National Institute for Occupational

Safety and Health,FACE Report No.97–15.

NIOSH [1999 ].Preventing worker deaths from uncontrolled release

of electrical,mechanical,and other types of hazardous energy.

Morgantown,WV:U.S. department of Health and Human Services,Public

Health Service,Centers for Disease Control and Prevention,National

Institute for Occupational Safety and Health,DHHS (NIOSH)Publication

No.99–146.

NIOSH [2000a ].Comments of the National Institute for Occupational

Safety and Health on the Department of Labor notice of proposed

rulemaking and request for comments on child labor regulations,orders,

and statements of interpretation. Child Labor Violations—Civil

Money Penalties:29 CFR Parts 570 and 579. Cincinnati,OH: U.S. department

of Health and Human Services,Public Health Service,Centers for

Disease Control and Prevention,National Institute for Occupational

Safety and Health,January 28,2000.

NIOSH [2000b ].Sixteen-year-old produce-market worker dies from

crushing injuries after being caught in a vertical downstroke

baler—New York. Morgantown,WV:U.S. Department of Health and

Human Services, Public Health Service,Centers for Disease Control

and Prevention,National Institute for Occupational Safety and

Health,FACE Report No.2000–19.

NIOSH [2000c ].Worker dies from crushing injuries after falling

into a baling machine—North Carolina. Morgantown,WV: U.S. department

of Health and Human Services,Public Health Service,Centers for

Disease Control and Prevention,National Institute for Occupational

Safety and Health,FACE Report No.2000–01.

NIOSH [2001 ].Thirty-six-year-old paper factory worker dies

from crushing injuries after being caught in a horizontal baler

— Pennsylvania. Morgantown,WV:U.S. department of Health and Human

Services, Public Health Service,Centers for Disease Control

and Prevention,National Institute for Occupational Safety and

Health,FACE Report No.2001–08.

NIOSH [2003 ].Unpublished analyses of the 1992–2000 Census of

Fatal Occupational Injuries special research files provided

to NIOSH by the Bureau of Labor Statistics. Morgantown,WV:Department

of Health and Human Services,Centers for Disease Control and

Prevention,National Institute for Occupational Safety and Health,Division

of Safety Research. Unpublished database.

NJ FACE [1996 ].Recycling center laborer crushed in a vertical

upstroke baling machine. Trenton,NJ:FACE Investigation No.96NJ026.

OSHA [1992 ].Concepts and techniques of machine guarding. Washington,DC:U.S.

Department of Labor,Occupational Safety and Health Administration,Publication

3067.

*FACE conducts

fatality investigations of selected categories of cases,including

machinery-related incidents,and disseminates injury prevention

information. Through a series of cooperative agreements with

NIOSH,15 States maintain multisource surveillance networks to

identify all traumatic occupational deaths,conduct site investigations

of selected incidents,and disseminate prevention information.

† Code of Federal Regulations .See CFR in references.

‡ Federal Register .See Fed. Reg.in references.

§ An interlock is a device or mechanism used to connect individual

components so that the action of one part of the equipment is

constrained by,or dependent on,another. In general,its purpose

is to prevent or interrupt the operation of machine components

under specified conditions,usually when a hazard is present.

As applied to balers and compactors,the interlock prevents or

interrupts movement of the compacting ram if the access doors

of the machine are opened while the machine is energized or

in motion.

Publication #: NIOSH 2003-124

Disclaimer and Reproduction Information: Information in

NASD does not represent NIOSH policy. Information included in

NASD appears by permission of the author and/or copyright holder.

More